• Reference Waveform

VEHICLE INFORMATIONS

YEAR

:

1986

MAKE : Nissan/Datsun

MODEL

:

Stanza Wagon

ENGINE : 2.0 L

FUELSYS : Multiport Fuel Injection

PCM_PIN : B WhtBlk wire

STATUS :

KOER (Key On Running)

RPM : Idle

ENG_TMP : Operating Temperature

VACUUM : 21 In. Hg

MILEAGE : 183513

IMPORTANT :On some European

vehicles like Jaguar,

there may be only

one release spike because the

first

release spike does not appear due to a spike suppression diode.

• Troubleshooting Tips

Spikes during on-time or unusual high turn off spikes indicate the injector driver’s malfunction.

Mixture Control Solenoid

• Theory of Operation

The mixture control signal is the most important output signal in a carbureted Feedback Fuel Control system. On a

GM vehicle, this circuit pulses about 10 times per second, with each individual pulse (pulse width or on-time) varing,

depending upon the fuel mixture needed at that moment.

In a GM vehicle, this circuit controls how long (per pulse) the main jet metering rods in the carburetor stay down

(lean position). Most feedback carburetor systems operate in the same way – more mixture control on-time means

lean mixture

command. Generally, mixture

control commands (from the PCM) tha

t

oscillate around duty cycles

greater than 50 % mean the system is commanding a lean mixture in an effort to compensate for a long term rich

condition.

• Symptoms

Hesitation on throttle tip in, poor fuel economy, erratic idle, rich or lean emissions

• Test Procedure

IMPORTANT :Before performing the test procedure, the O

2

sensor must be tested and confirmed good.

1.

Connect the CH A lead to the mixture solenoid control signal from the PCM and its ground lead to GND.

6-39

When the Feedback Fuel Control System controls

fuel mixture properly, the injector

on-time will modulate from about 1-6 ms at idle to about 6-35 ms under cold cranking

or Wide Open Throttle (WOT) operation.

The injector coil release spike(s) ranges are from 30 V to 100 V normally.

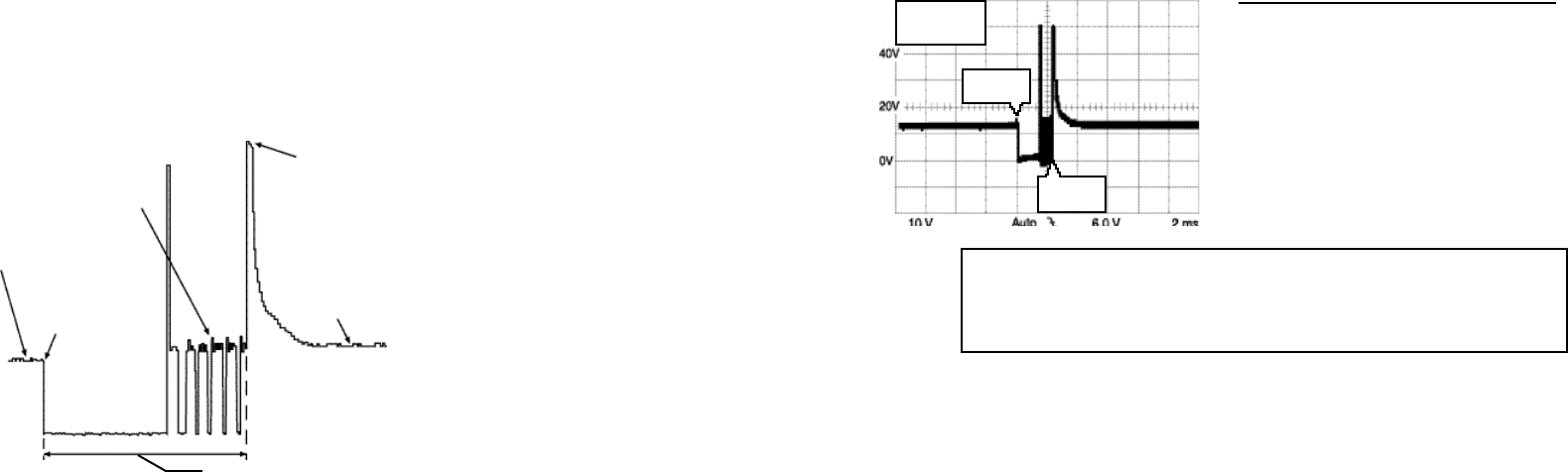

MAX = 50.6 V

MIN = -3.33 V

DUR = 2.23 ms

PCM turns

circuit off

PCM turns

circuit on

Bosch-Type Peak and Hold Injector

• Theory of Operation

Bosch type Peak and Hold injector drivers (within the PCM) are designed to allow about 4 A to flow through the

injector coil, then reduce the flow to a maximum of 1 A by pulsing the circuit on and off at a high frequency. The

other type injector drivers reduce the current by using a “switch-in” resistor, but this type drivers reduce the current

by pulsing the circuit on and off.

Bosch ty pe Peak and Hold i njector

drivers are found on a few

E

uropean

models with MFI systems and

some

early to

mid-1980s Asian vehicles with

MFI systems.

• Symptoms

Hesitation on throttle tip in, rough idle, intermittent stall at idle, poor fuel mileage, emissions test failure, low power on

acceleration

• Test Procedure

1. Connect the CH A lead to the injector control signal from the PCM and its ground lead to the injector GND.

2. Start the engine and hold

t

hrottle at

2500 RPM for 2-3 minutes until the engine is fully warmed up and

t

he

Feedback Fuel System enters closed loop. (Verify this by reviewing the O

2

sensor signal, if necessary.)

3. Shut off A/C and all other accessories. Put vehicle in park or neutral. Rev the engine slightly and watch for the

corresponding injector on-time increase on acceleration.

1) Induce propane into the intake and drive the mixture rich. If the system is working properly, the injector on-

time will decrease.

2) Create a vacuum leak and drive the mixture lean. The injector on-time will increase.

3) Raise the engine to 2500 RPM and hold it steady. The injector on-time will modulate from slightly larger to

slightly smaller as the system control the mixture. Generally, the injector on-time only has to change from 0.25

ms to 0.5 ms to drive the system through its normal full rich to full lean range.

IMPORTANT: If the injector on-time is not changing, either the system may be operating in an “open loop” idle

mode or the O

2

sensor may be bad.

4. Use the Glitch Snare mode to check for sudden changes in the injector on-time.

6-38

Peak voltage caused

by the collapse of the

injector coil. when

current is reduced.

Current flow

pulsed on and

off enough to

keep hold in

winding activated

Battery voltage

(or source voltage)

supplied to the

injector

Return to battery

(or source) voltage

Driver transistor

turns on, pulling

the injector pintle

away from its

seat, starting fuel

flow

Injector On-Time