Diesel Glow Plug

• Theory of Operation

Starting cold diesel engines are not easy because Blowby past the

piston rings and thermal losses reduce the

amount of

compression possible. Cold starting

can be improved by a shea

t

hed element glow plug in

t

he

precombustion chamber (in case of Direct-injection (DI) engines, in the main combustian chamber).

When current flows through the heating coil of the glow plug, a portion of the fuel around the glow plug’s hot tip is

vaporized to assist in igniting the air-fuel mixture. Newer glow plug systems, which continue to operate after engine

startup for up to 3 minutes, improve initial engine performance, reduce smokes, emissions, and combustian noises.

Usually, a glow plug control unit supplies power to the glow plug during appropriate conditions. Some newer glow

plugs

are designed with a heater element that changes resis

t

ance wi

t

h temperature.

The glow plug’s resistance

increases as the heating element gets hotter by the combustian temperature’s increment after startup.

Usually, glow plug systems are power feed controlled so the waveform of the

current

going

t

hrough

its heating

element appears as a straight line at 0 V until the ignition key is switched on.

• Symptoms

No or hard start, emissions with excessive smokes, excessive combustian noises (knocks)

• Test Procedure

1. Set the instrument up with the current probe. (Connect the probe to the CH A.)

2. Adjust the probe to read DC Zero.

3. Clamp the current probe around the glow plug feed wire.

4. With the diesel engine stone cold, turn on the ignition key and watch for the readings.

5. Make sure that the amplitude of the current is correct and consistent for the glow plug systems under test.

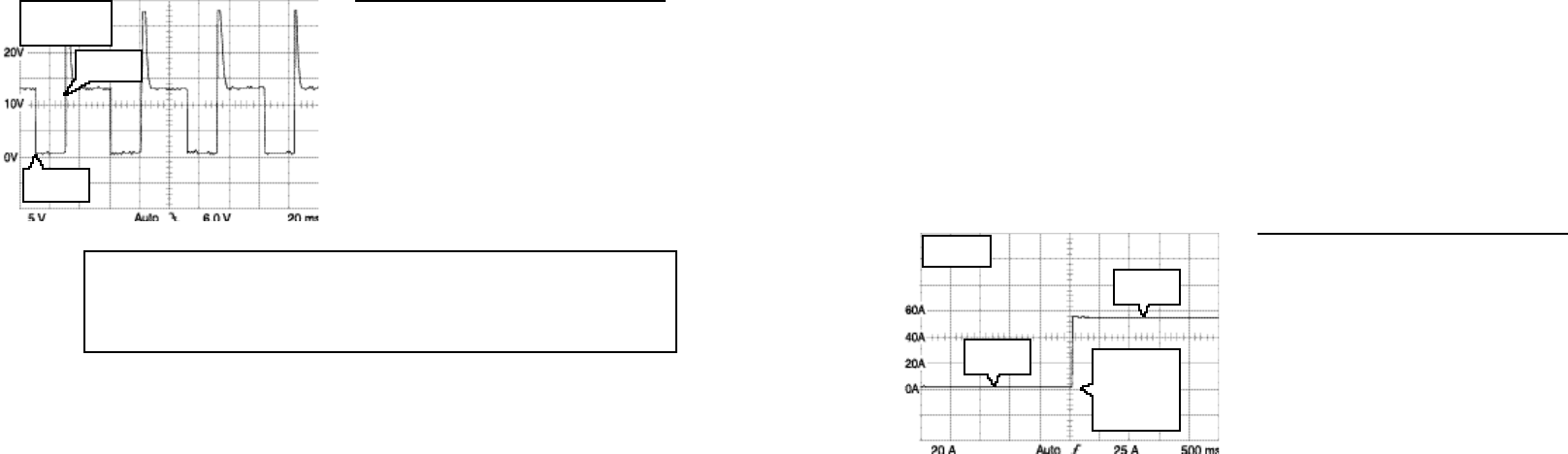

• Reference Waveform

VEHICLE INFORMATIONS

YEAR

:

1977

MAKE : Mercedes-Benz

MODEL : 240 D

ENGINE : 2.4 L

FUELSYS : Multiport Fuel Injection

PCM_PIN : Power supply to glow plugs

STATUS

:

KOEO (Key On Engine Off)

RPM : 0

ENG_TMP : Ambient Temperature

VACUUM

: 0 In. Hg

MILEAGE

: 151417

6-47

MAX = 56 A

MIN = 1 A

Ignition key

switched on.

Current begins

to flow through

glow plugs.

Ignition key

on

Ignition key

off

A door (called the wastegate) is opened and closed to regulate the amount of bypass. The wastegate is controlled

by a vacuum servo motor, which can be controlled by a vacuum solenoid valve that receives a control signal from

the PCM. When the PCM receives a signal from the MAP sensor indicating that certain boost pressure is reached,

the PCM commands the vacuum solenoid valve to open in order to decrease boost pressure. The PCM opens the

solenoid valve via a pulse width modulated signal.

• Symptoms

Poor driveability, engine damage (blown head gasket), hard stall under acceleration

• Test Procedure

1. Connect the CH A lead to the solenoid control signal from the PCM and its ground lead to the chassis GND.

2.

S

tart the

engine and

hold thro

t

tle at 2500 RPM

for

2-3 minu

t

es until the engine is

f

ully warmed

up and the

Feedback Fuel system enters closed loop. (Verify this by viewing the O

2

sensor signal, if necessary.)

3. Drive the vehicle as needed to make the suspected problem occur.

4. Make sure that the drive signal comes on as the boost pressure is regulated and the wastegate actually responds

to the solenoid control signal.

•

Reference Waveform

VEHICLE INFORMATIONS

YEAR

:

1988

MAKE : Chrysler

MODEL : LeBaron Convertible

ENGINE :

2.2 L Turbo

FUELSYS : Multiport Fuel Injection

PCM_PIN : 39 LtGrn Blk wire

STATUS : KOBD (Key On Driven)

RPM : Moderate Acceleration (35 MPH)

ENG_TMP : Operating Temperature

VACUUM : 5 In. Hg

MILEAGE : 77008

• Troubleshooting Tips

If the turn off spikes are not present, the solenoid coil may be shorted.

If the drive signal never appears under the high boost conditions, the driver within the PCM may have failed.

If the turn off spikes are runted (shortened), the vacuum solenoid valve may be shorted.

6-46

As soon as the turbo engine reaches a predetermined

boost pressure under

acceleration,

t

he PCM should begin pulsing the turbo boost

solenoid wi

t

h a varying

pulse width modulated signal

t

o open the was

t

ega

t

e. On deceleration, the signal is

stopped and the valve is closed.

FREQ = 19.5 Hz

DUTY = 39.2 %

MAX = 28.0 V

PCM turns

circuit on

PCM turns

circuit off