1

10

2

4

5

6 8

7

7

9

8

9

6

2

4

5

3

3

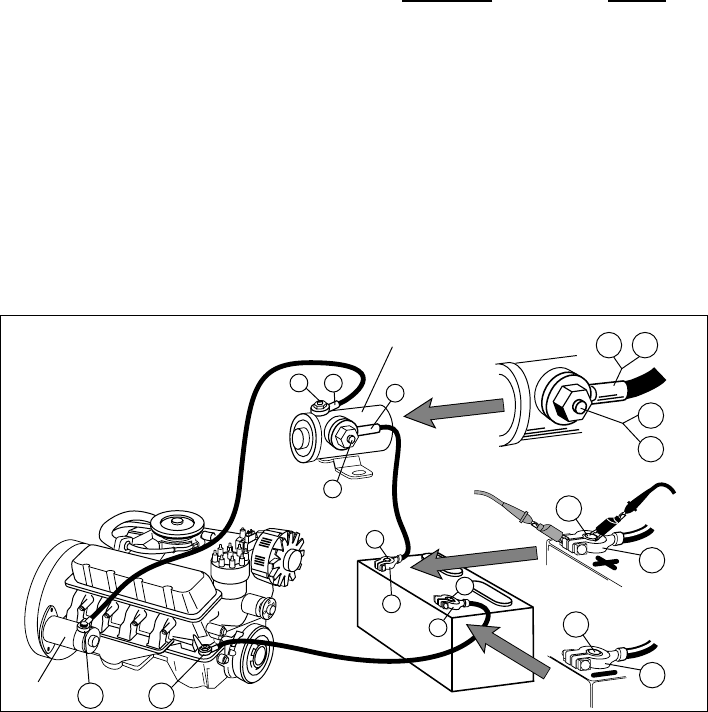

17

Voltage Drops

5. Turn multimeter rotary switch to

200mV DC range.

If multimeter overranges, turn multimeter

rotary switch to the 2V DC range. (See

Setting the Range on page 6)

6. Crank engine until steady reading is on

display.

Record results at each point as

displayed on multimeter.

Repeat Step 4 & 5 until all points are

checked.

7. Test Results

Estimated Voltage Drop of Starter

Circuit Components

Component Voltage

Switches 300mV

Wire or Cable 200mV

Ground 100mV

Battery Cable Connectors 50mV

Connections 0.0 V

Compare voltage readings in Step 6

with above chart.

If any voltages read high, inspect

component and connection for defects.

If defects are found, service as

necessary.

This test measures the voltage drop across

wires, switches, cables, solenoids, and

connections. With this test you can find

excessive resistance in the starter system.

This resistance restricts the amount of

current that reaches the starter motor

resulting in low battery load voltage and a

slow cranking engine at starting.

Test Procedure (see Fig. 18):

1. Disable ignition system so vehicle

wont start.

Disconnect the primary of the ignition coil

or the distributor pick-up coil or the cam/

crank sensor to disable the ignition

system. Refer to vehicle service manual

for disabling procedure.

2. Insert BLACK test lead into the COM

test lead jack.

3. Insert RED test lead into the test lead

jack.

4. Connect test leads.

Refer to Typical Cranking Voltage Loss

Circuit (Fig. 18).

Connect RED and BLACK test leads

alternately between 1 & 2, 2 & 3, 4 & 5,

5 & 6, 6 & 7, 7 & 8, 8 & 9, and 8 & 10.

Red

Black

Fig. 18 Typical Cranking

Voltage Loss Circuit

Solenoid

This is a representative sample of

one type of cranking circuit. Your

vehicle may use a different circuit with

different components or locations.

Consult your vehicle service manual.

Starter