28

Reference Manual

00809-0700-4530, Rev AA

Section 2: Installation Considerations

September 2013

Installation considerations

2.5 Solids measurement

Solids generally provide a difficult measuring environment with low dielectric products in tall

tanks, where pull forces may act on the probe, and dust, steam, or risk of coating are often

present. In addition, the surface is not flat and the angle of repose tends to change. As a result,

the signal levels are often very low, and installation is of utmost importance.

2.5.1 Rosemount 5303

Adding to the installation considerations described in “Tank installations” on page 22, when

measuring solids, it is also important to consider the following:

Mount the probe as far away as possible from filling and emptying ports. This will

minimize load and wear, and will help to avoid disturbances from the incoming product

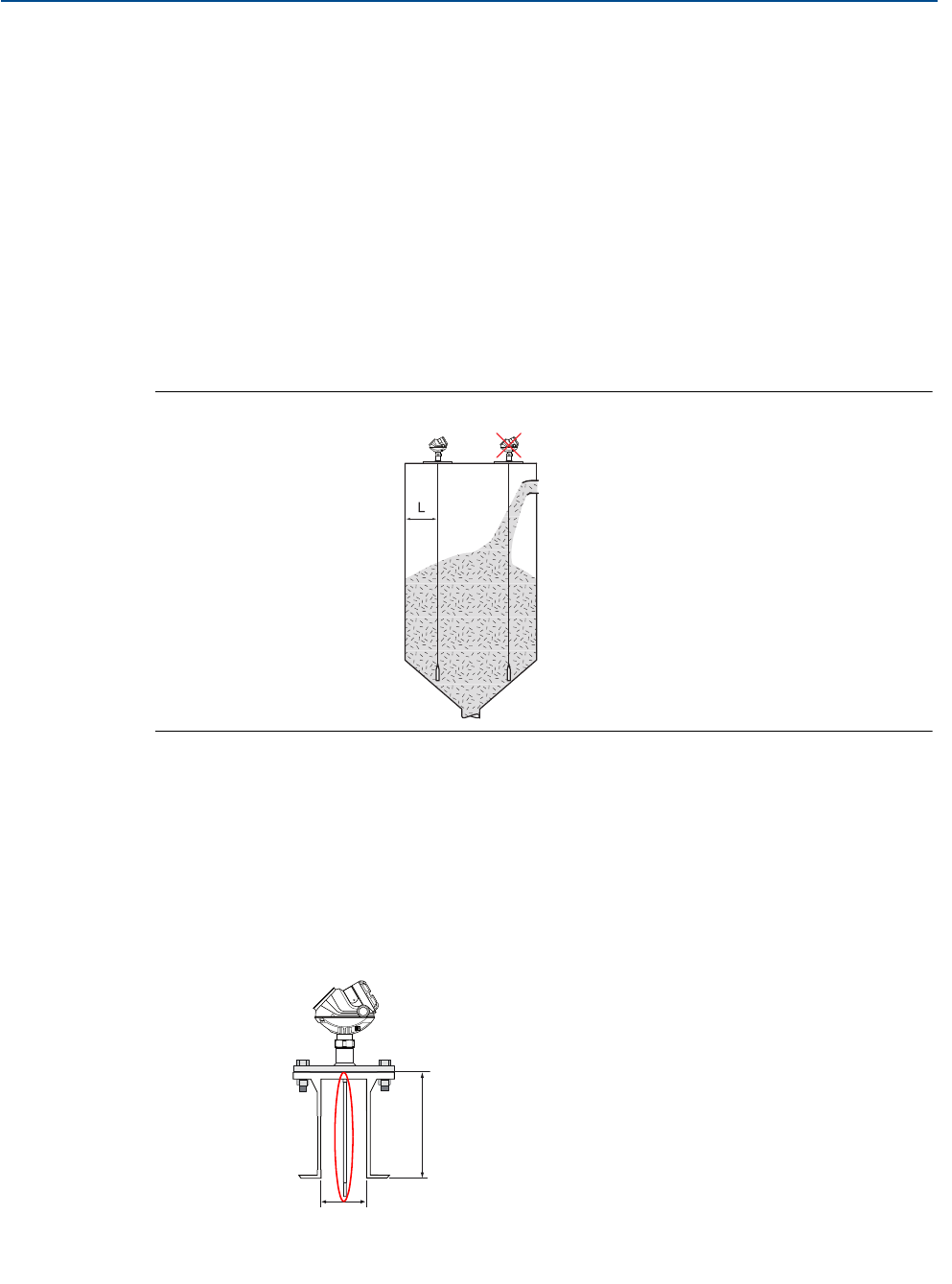

Figure 2-20. Rosemount 5303 solids recommended mounting position

Installing the probe at about

1

/3 to

1

/2 of the silo radius is recommended to compensate

for measurement errors caused by centered filling of the material cone.

The minimum recommended probe distance to tank wall or disturbing object is 20 in.

(50 cm), unless the wall is comprised of smooth metal. Then the distance is 4 in.

(10 cm). In any case, the probe should not be able to touch the wall of the tank during

operation.

The maximum recommended nozzle height is nozzle diameter + 4 in. (100 mm).

When nozzles are more than 4 in. (100 mm) in height, a Long Stud (LS option) is

recommended to prevent the probe from contacting the nozzle.

For flexible single lead probes,

the minimum clearance to the

tank wall (L) or obstruction is

4 in. (10 cm) in the case of

smooth metallic walls, and

20 in. (50 cm) in the case of

disturbing objects, rugged

metallic or concrete/plastic

walls.

Long stud

(9.8 in./250 mm)

Nozzle

height

Nozzle diameter