7

Reference Manual

00809-0700-4530, Rev AA

Section 2: Installation Considerations

September 2013

Installation considerations

Apart from the additional cost of installation, there are some sizing and selection criteria for the

radar gauges that must be considered. This document outlines those considerations.

GWR is the preferred technology for shorter installations where rigid probes may be used. This

makes it a suitable replacement for caged displacers, which are often less than 10 ft. (3 m). The

probes are available in a variety of materials to handle corrosive fluids.

For further information on how to replace displacers with GWR in existing chambers, see the

Replacing Displacers with Guided Wave Radar Technical Note (Document No.

00840-2200-4811).

For taller applications or those with limited head space for installing rigid probes,

non-contacting radar may be advantageous. Non-contacting radar is also the preferred

technology for applications with heavy deposition or very sticky and viscous fluids.

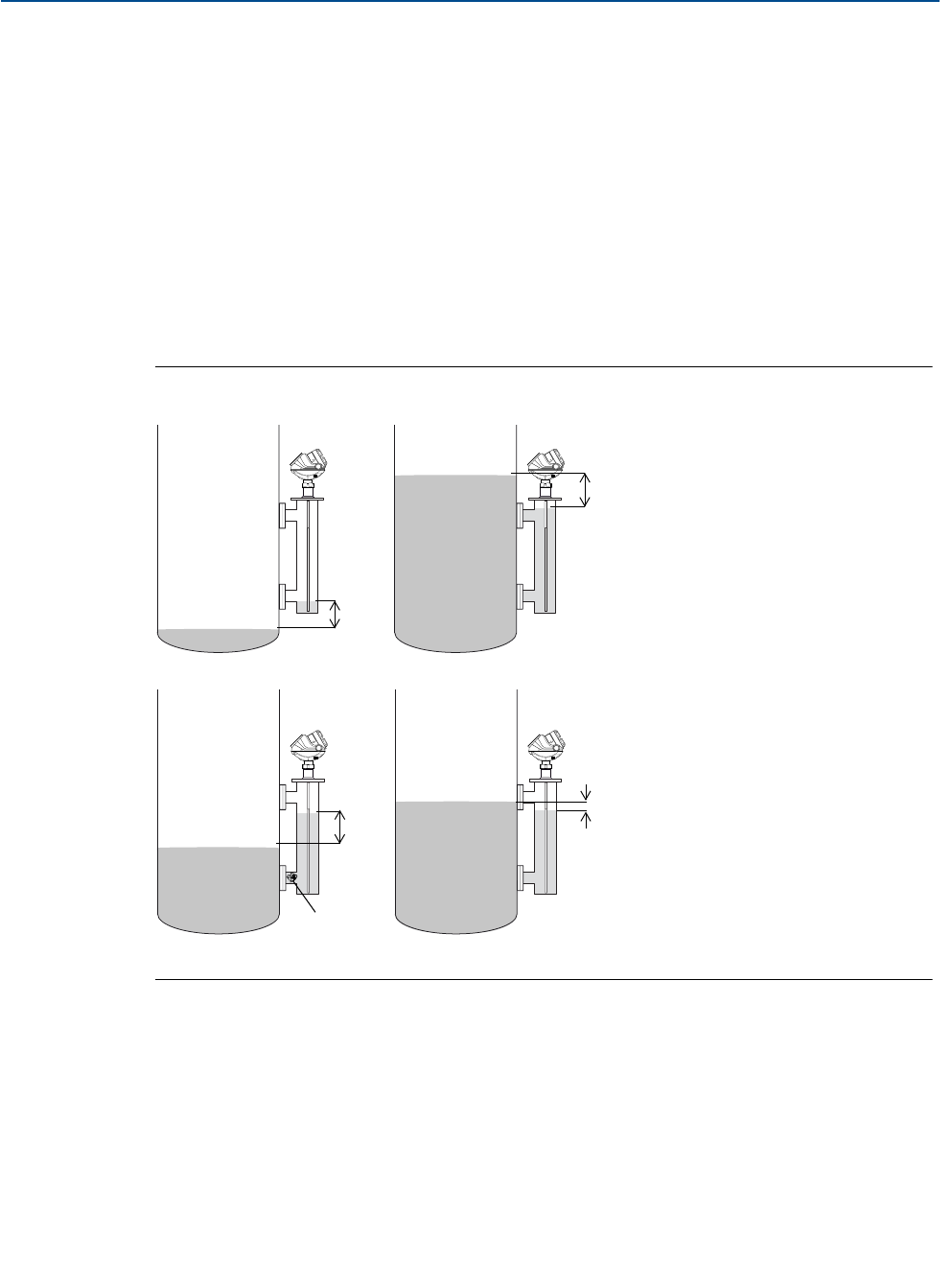

Figure 2-1. Possible error sources in chamber installations

For application guidelines, see Section 1: Power applications.

2.3.1 High pressure steam applications

Phase changes

It is especially common during startup to experience varying temperature and pressure. Both

the liquid and steam phases of the system will have density changes as the system reaches the

operating temperature and pressure which can cause up to a 30% error over temperature up to

600 °F (315 °C), as seen in Ta bl e 2- 1.

Error

Error

Error

Inlet-pipe

clogged

Error

300 °F (150 °C)

SG=0.80

150 °F (65 °C)

SG=0.85