80

Reference Manual

00809-0700-4530, Rev AA

Section 5: Troubleshooting Procedures

September 2013

Troubleshooting procedures

Potential problems include:

Fluid density changes: source, grade, product and temperature affect the density of

the fluid, and thereby the level output.

In case of a wet leg, is it completely filled? Or, if a dry leg is used, is it really dry? Loss of

fluid and condensed fluid respectively create an offset in the level reading. Consider

using either an electronic or a capillary remote seal.

If a fill fluid is used, is its density known? Has the transmitter been scaled correctly?

If a single pressure transmitter is used, process pressure will create an offset in the level

reading. A differential pressure transmitter should be used.

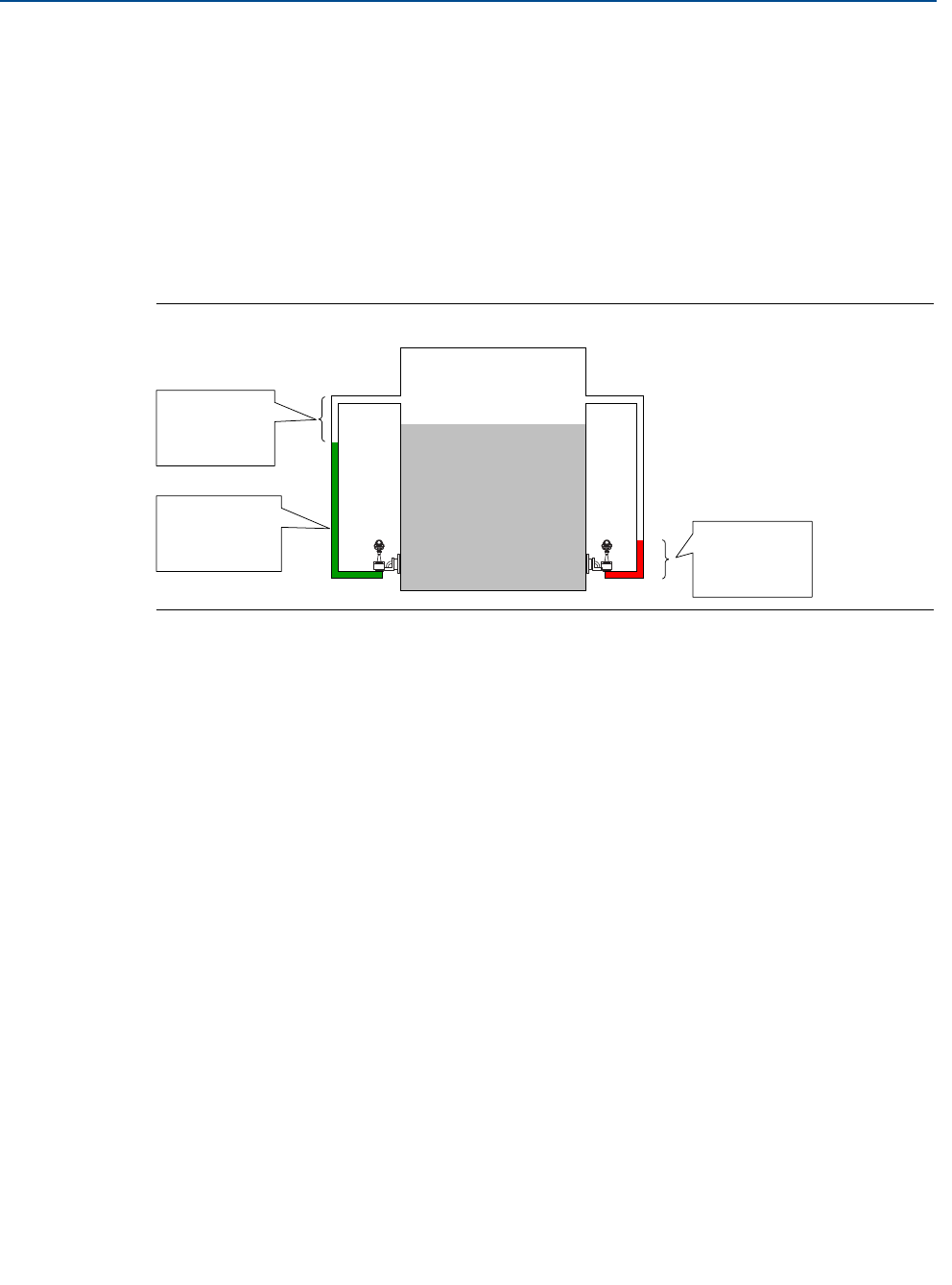

Figure 5-23. Differential pressure transmitter

Wet Leg:

Level offset is

created by

incomplete fill

Density of fill

fluid must be

known

Dry Leg:

Level offset is

created by

condensed fluid