TRANSFER BOX

26

OVERHAUL

COMPONENT ASSEMBLING

1. Lubricate all components with recommended

oil.

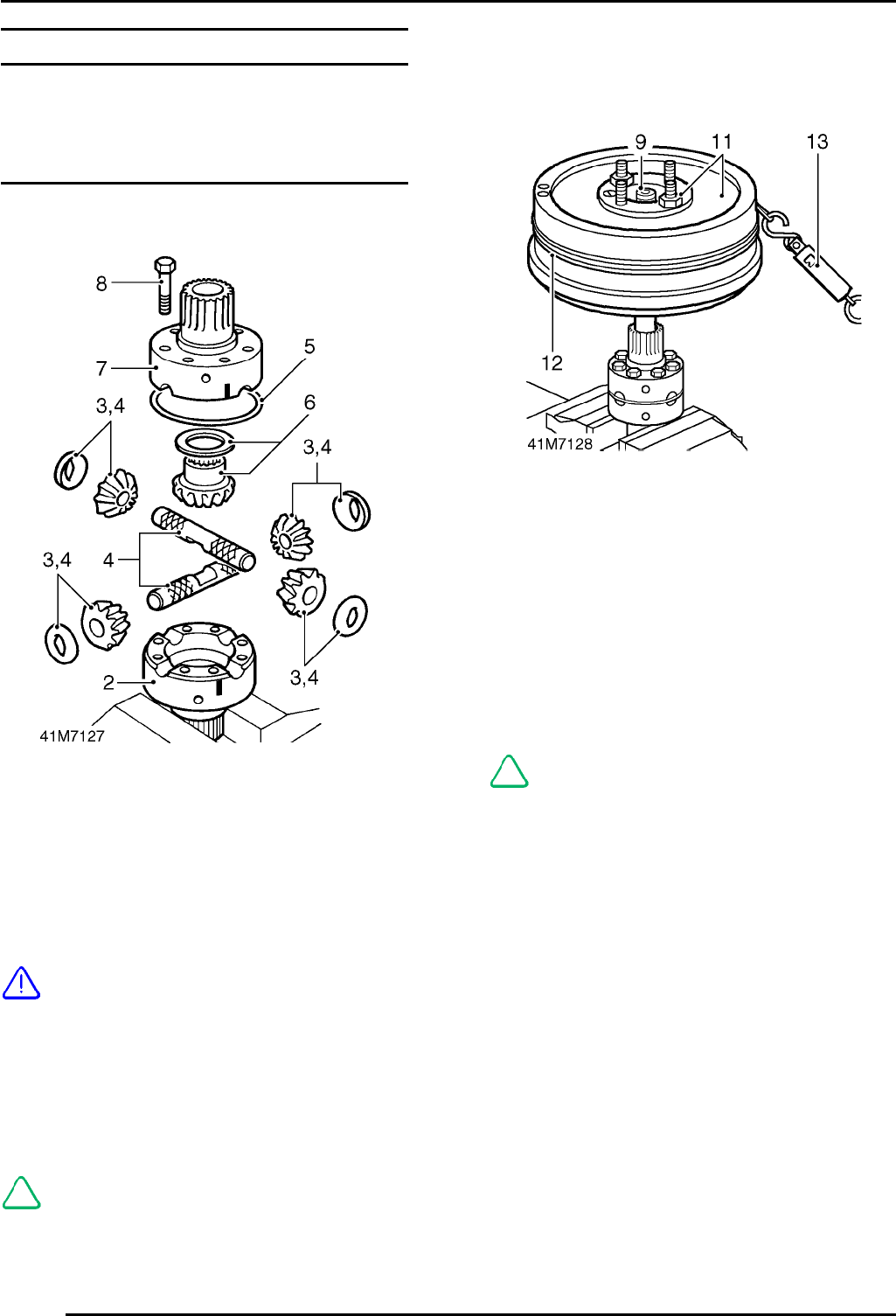

Differential

1. Lightly oil threads of differential bolts.

2. Secure rear half of differential carrier in a

soft-jawed vice.

3. Fit each planet gear to its respective

cross-shaft, fit new dished thrust washer to

each gear.

4. Fit cross-shafts, planet gears and dished thrust

washers in rear half carrier.

CAUTION: Ensure that cross-shafts are in

their correct fitted position in rear half

carrier. Do not fit sun gear into rear half

carrier at this stage.

5. Fit retaining ring.

6. Fit a 1.05 mm (0.04 in) thick thrust washer to

front half carrier sun gear, position gear in front

half carrier.

NOTE: This is the thinnest of the thrust

washers available.

7. Fit front half carrier to rear ensuring that

alignment marks are together.

8. Fit bolts and tighten by diagonal selection to 60

Nm (44 lbf.ft).

9. Insert front output shaft into front half carrier,

check that gears rotate freely.

10. Fit output flange on to splines of output shaft,

do not fit flange nut at this stage.

11. Fit transmission brake drum to output flange,

secure drum using 2 nuts.

12. Secure a length of cord around brake drum,

attach one end of cord to a spring balance.

13. Tension cord and note load to turn figure

recorded on spring balance when brake drum

rotates.

NOTE: Used gears should rotate smoothly

whilst new gears will have a ’notchy’ feel

as they rotate.

14. Check figure obtained against specified load to

turn figure:

Used gears = 0.45 kg (1.0 lb)

New gears = 1.72 kg (3.8 lb)