34 Use of appropriate safety engineered swivel hoist rings in meter end flanges

Section 2: Mechanical installation Daniel 3812 Liquid Ultrasonic Flow Meter Installation Manual

March 2013 3-9000-765 Rev D

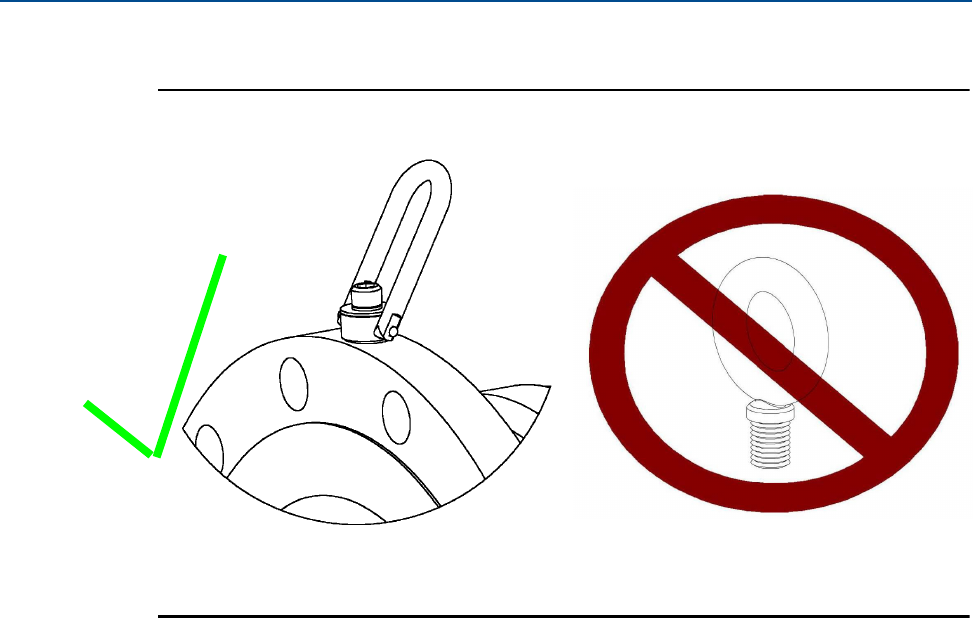

Figure 2-8 Safety approved hoist ring and non-compliant eye bolt

Safety precautions using safety engineered swivel hoist rings

Read and follow the Safety Precautions listed below:

1. Meters must only be lifted by personnel properly trained in the safe practices of rigging

an

d lifting.

2. Remove the plug bolts installed in the tapped ho

les on the top of the flanges. Do not

discard the bolts as they must be reinstalled once the lifting operation is complete to

prevent corrosion of the tapped holes.

3. Make sure the tapped holes on the meter are clean and free of debris before installing

the ho

ist rings.

4. Use only the safety engineered swivel hoist ri

ngs that are rated for lifting the meter. Do

not use any other type of hoist rings with the same screw size or heavy duty hoist rings.

The meter tapping and counter bore size are suitable only for the hoist rings specified

by Daniel.

5. When installing a hoist ring, make sure the base surface of the hoist ring fully contacts

t

he machined flat surface of the tapped hole. If the two surfaces do not come in contact

then the hoist ring will not hold its full rated load. Torque the hoist ring attachment

bolts to the limit indicated on the hoist rings.

6. After installation of the hoist rings, always check that the ring rotates and pivots freely

in

all directions.

7. NEVER attempt to lift the meter using only one hoist ring.

Eye bolt

Safety engineered swivel hoist ring