14 Meter specifications

Section 1: Introduction Daniel 3812 Liquid Ultrasonic Flow Meter Installation Manual

March 2013 3-9000-765 Rev D

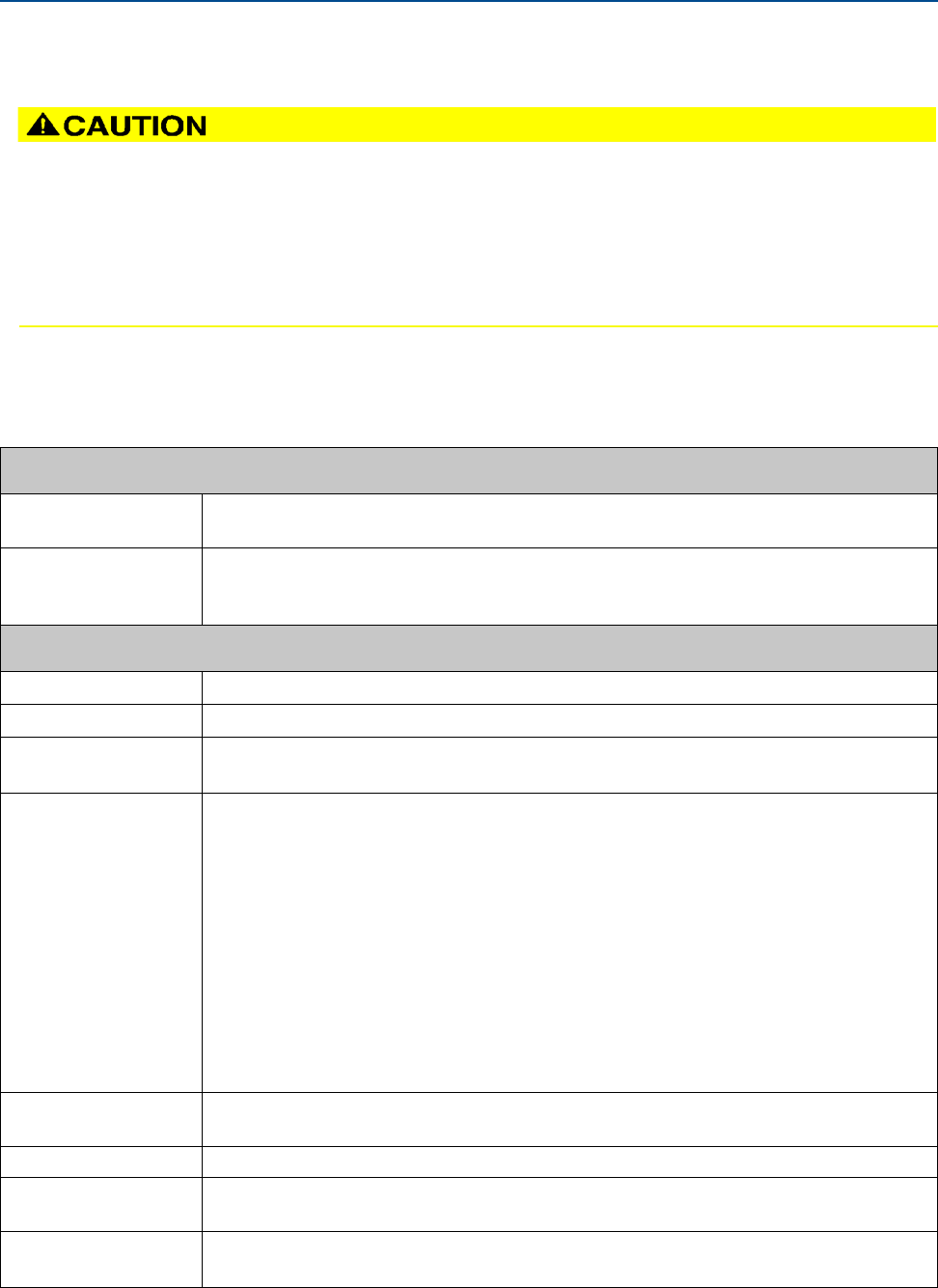

1.6 Meter specifications

Consult your Daniel Sales and Service representative to ensure you purchase the correct

c

omponents and seals for your application.

Table 1-2 Meter specifications

Liquid Ultrasonic Flow Meter specifications

Meter type Number of paths

• Two path (four transducer) chordal design

Ultrasonic type

• Transit-time based measurement

• Spool piece with integral mount transducers

Meter Performance

Linearity

• ± 0.30% of measured value over a 10:1 turndown (40 to 4 ft/s; 12.2 to 1.2 m/s)

Repeatability

• ±0.10% of reading in the specified velocity range

Velocity range

• 40.0 ft/s (12.2 m/s) (nominal) to 2.0 ft/s (0.6 m/s)

• 48 fps (14.3 m/s) (over-range)

Body and Flange Pressure

rating range

U.S. Customary Units sizes - 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24, 28, 30, and 36 (in)

• ANSI pressure classes 150 and 300, 600, 900 (per ANSI B16.5)

• Carbon Steel

• 316 Stainless Steel

Metric Units sizes

• DN 50, 75, 100, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 750, and 900

• PN 20, 50, 100, 150

• Carbon Steel

• 316 Stainless Steel

Meter bore

• Schedule 40 and Schedule 80

Maximum Pressures

• Dependent on operating temperature

Flange types ANSI classes - 150, 300, 600 and 900

• Raised face or RTJ

Specific Gravity 0.35 to 1.50

Accuracy Limits Accuracy limits typically are:

• ± 2% without a flow calibration, ± 0.3% with flow calibration

Minimum operating

pre

ssure

• 0 psig

• 0 barg

ESCAPING FLUIDS HAZARD

The purchaser of the meter is responsible for the selection of Daniel components/seals and materials

compatible with the chemical properties of the measurement fluid.

Failure to select suitable meter components/seals may cause escaping fluids, resulting in injury or equipment

damage.