Daniel 3812 Liquid Ultrasonic Flow Meter Installation Manual Section 2: Mechanical installation

3-9000-765 Rev D March 2013

Piping recommendations 31

Meter tube dimensions with tube bundle or profiler plate for uni-directional and bi-directional

flow, the minimum straight pipe length is as follows:

• T

he bore of the mating piping should be within 1% of the meter inside diameter.

• The met

er is provided with dowel pins to align the meter body bore with the bore of the

mating piping.

• The

Daniel Liquid Ultrasonic Flow Meter should be mounted in horizontal piping with

the chord paths horizontal

• Norm

ally, the meter body is installed so that the electronics assembly is on the top of

the meter. If there is insufficient space above the piping for this arrangement, the meter

can be ordered with extra long transducer cables for remote mounting or the meter

housing can be installed with the electronics assembly on the bottom.

• T

he mating piping should include temperature and pressure measurement

connections located a minimum of two nominal pipe diameters length down stream of

the meter, or per API MPMS 5.8.

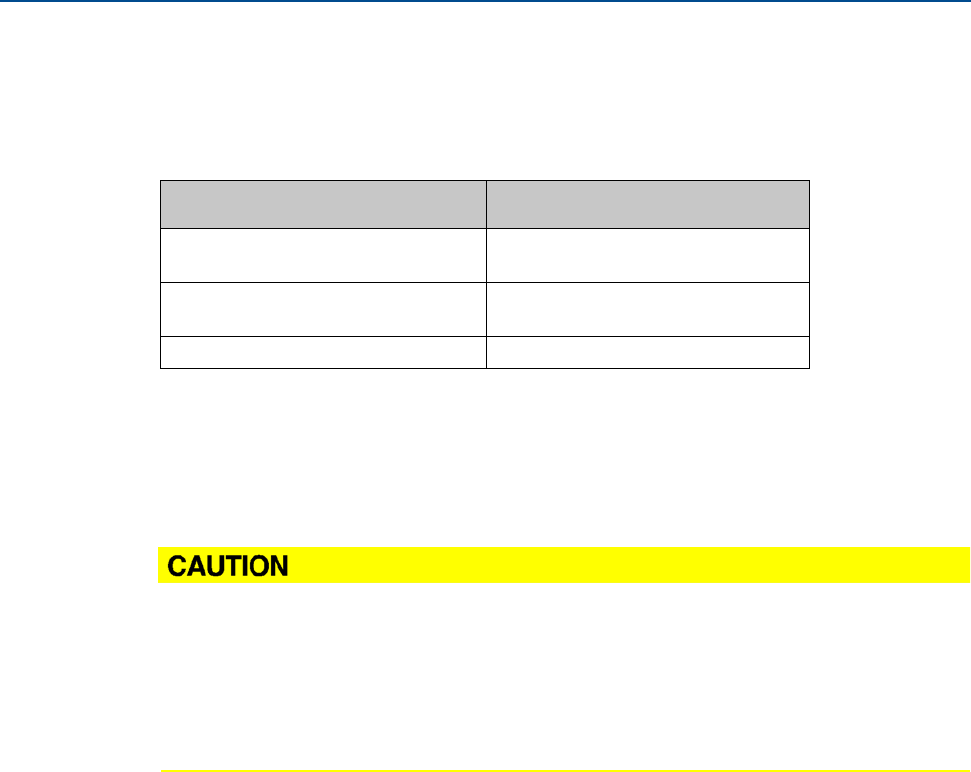

Table 2-2 Piping recommendation for uni-directional or bi-directional flow

UniDirectional Flow BiDirectional Flow

8D up stream

(with a flow conditioner)

8D up stream

(with a flow conditioner)

8D up stream

(no flow conditioner)

8D up stream

(no flow conditioner)

5D in front of flow conditioners if used 5D in front of flow conditioners if used

FAULTY METER INSTALLATION

Correctly install the meter.

If meter bodies are mounted or oriented differently than specified above, debris may collect in

the transducer ports which could adversely affect the transducer signals, or cause equipment

damage.