Daniel 3812 Liquid Ultrasonic Flow Meter Installation Manual Section 2: Mechanical installation

3-9000-765 Rev D March 2013

Use of appropriate safety engineered swivel hoist rings in meter end flanges 33

When lifting a Daniel Ultrasonic Meter by itself, Daniel recommends two methods. These

methods are:

• U

sing appropriately rated Safety Engineered Swivel Hoist Rings installed in the Daniel

Ultrasonic Meter end flanges.

• U

sing appropriately rated lifting slings positioned at designated areas of the Daniel

Ultrasonic Meter.

Both methods must be used in conjunction with all appropriate company hoisting and rigging

st

andards or the

DOE-STD-1090-2004 HOISTING AND RIGGING standard if such company

standards do not exist. Refer to the following sections for more information on these two

methods.

2.3.1 Use of appropriate safety engineered swivel hoist rings in

meter end flanges

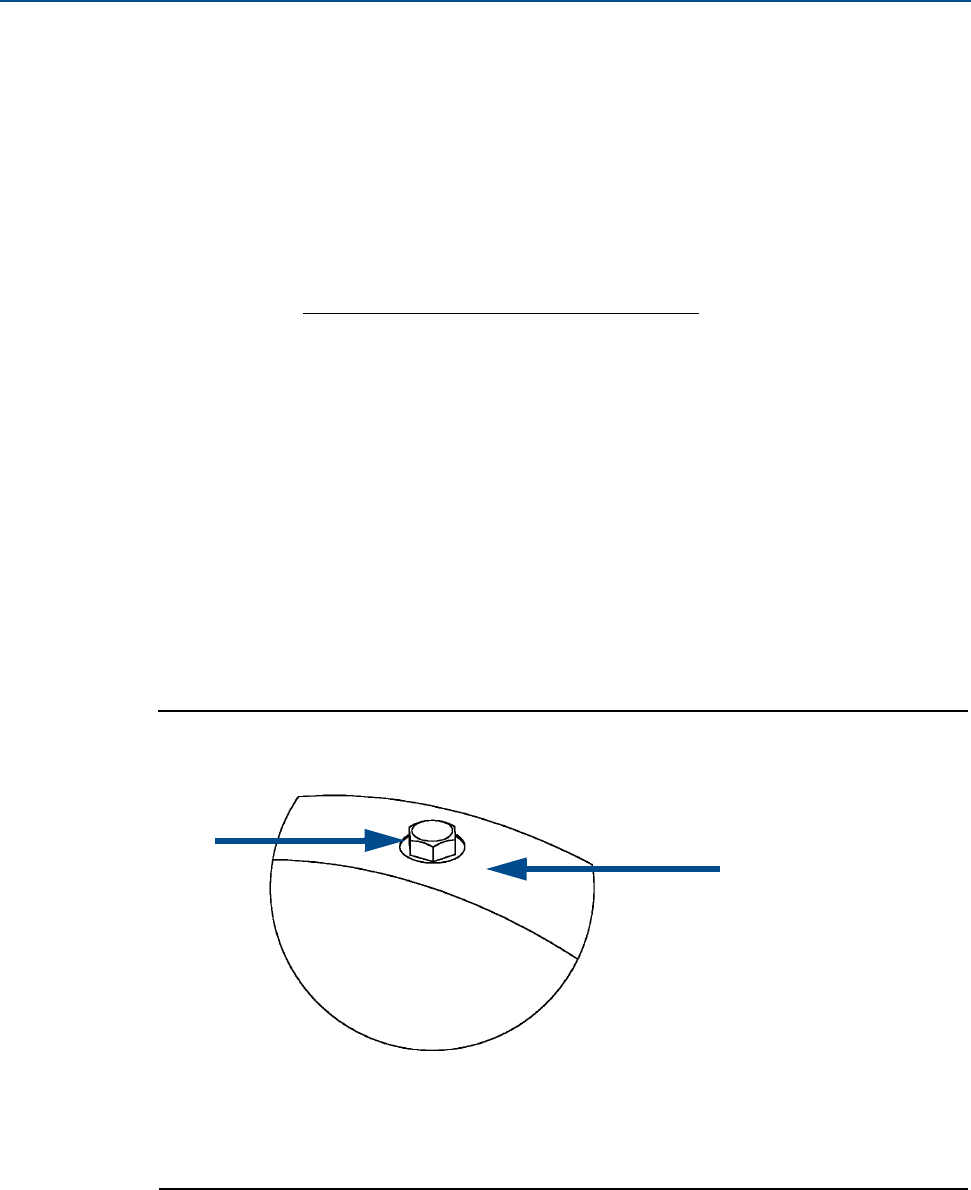

Daniel Ultrasonic meters come equipped with a tapped hole located on the top of each meter

body end flange. A flat machined surface surrounds each tapped hole (see Figure 2-7). This

feature provides complete surface contact ONLY between the meter flange and an OSHA

c

ompliant Safety Engineered Swivel Hoist Ring as shown in Figure 2-8.

Operators SH

ALL NOT use Eye Bolts (see Figure 2-8) in the Daniel Ultrasonic Meter flange tapped

holes to aid in lifting or maneuvering the unit.

Operators S

HALL NOT use other Hoist Rings that do not fully seat flush with the counter bore on

the top of the meter flanges.

Figure 2-7 Meter end flange with tapped

flat-counterbore hole for hoist ring

A. Plug bolt

B. Flat counterbore surface

A.

B.