11

12

CHARGING SYSTEMS

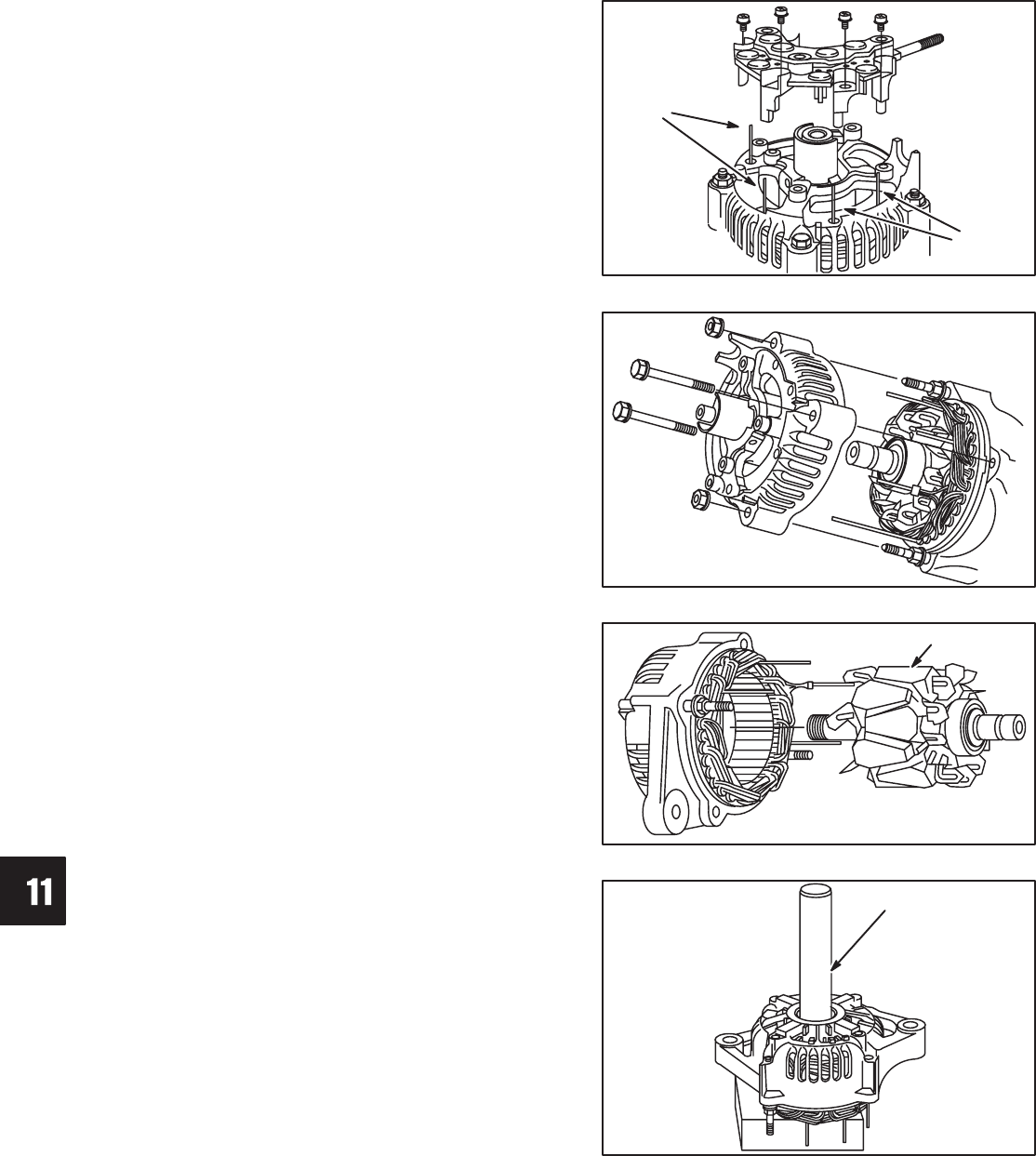

6. Remove four stator lead screws from rectifier,

Fig. 26.

a. Carefully straighten stator leads.

b. Remove rectifier.

Fig. 26 – Remove Rectifier

STATOR

LEADS

STATOR

LEADS

7. Scribe or place a reference mark on drive end and

brush end housing so that they may be

re-assembled in original position.

8. Remove two nuts and two thru bolts.

9. Remove brush end housing being careful not to

damage stator leads, Fig. 27.

Fig. 27 – Remove Brush End Housing

10. Remove rotor from drive end housing, Fig. 28.

Note: Stator is NOT removable.

Fig. 28 – Remove Rotor

ROTOR

CHECKING BEARINGS

Ball bearings must rotate freely. If any rough spots are

felt the ball bearing must be replaced.

Note: Rotor and ball bearing are an assembly. If

bearing is worn, replace rotor assembly.

Remove Ball Bearing

1. Remove four screws and bearing retainer, Fig. 29.

2. Support drive housing on blocks.

3. Press out bearing from pulley side of drive end

housing using driver #19416.

DO NOT re-use ball bearings that have been removed

from drive end housing. The bearing races are usually

damaged during removal.

Fig. 29 – Remove Bearing Retainer

19416 DRIVER