10

11

ENGINE SPEED

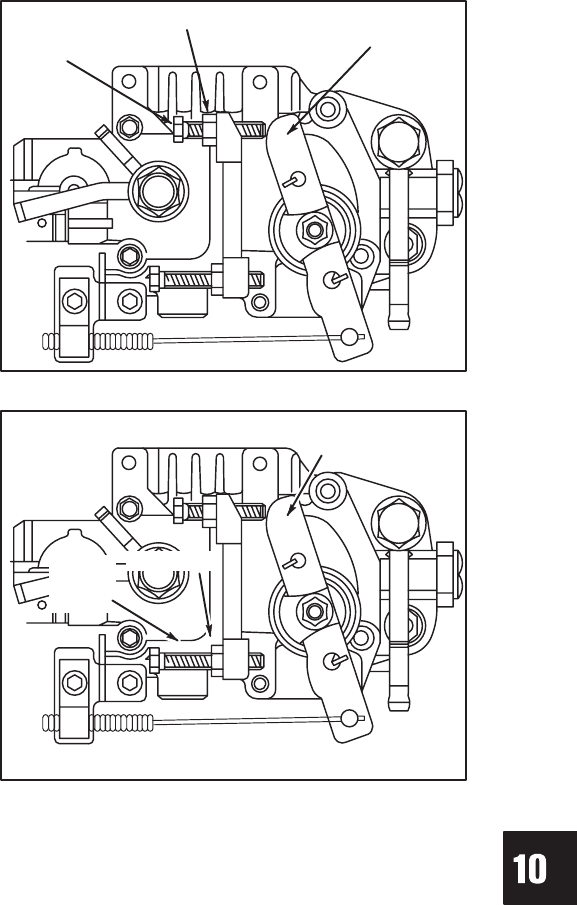

ADJUST IDLE SPEED

Engine should be at operating temperature before

adjusting idle speed.

Make sure speed control lever contacts idle speed

screw with engine at idle.

1. Loosen idle speed screw lock nut and adjust idle

speed screw to obtain RPM specified by model

and type number shown in chart, Fig. 23.

NOTE: Do exceed RPM shown for specific model

and type number.

a. Torque lock nut to 6.0 Nm (50 in. lbs.).

Fig. 23 – Adjusting Idle Speed

IDLE

SPEED

SCREW

SPEED

CONTROL

LEVER

LOCK NUT

ADJUST TOP NO LOAD SPEED

Engine should be at operating temperature before

adjusting idle speed.

Temporarily disconnect speed control wire at control

bracket on pump.

1. Remove and discard top no load wire and seal.

2. Loosen top no load speed screw lock nut.

3. Move speed control lever to FAST position and

adjust top no load speed screw to RPM specified

by model and type number shown in chart, Fig. 24.

NOTE: Do exceed RPM shown for specific model

and type number.

4. Stop engine and torque lock nut to 6.0 Nm

(50 in. lbs.).

5. Reassemble speed control wire at bracket.

a. Tighten screws securely.

b. Make sure speed control lever contacts top

no load screw when throttle lever is in

FAST position.

Fig. 24 – Adjusting Top No Load Speed

TOP NO

LOAD

SPEED

SCREW

SPEED

CONTROL

LEVER

LOCK NUT