2

14

CYLINDER HEAD AND VALVES

ADJUST VALVES

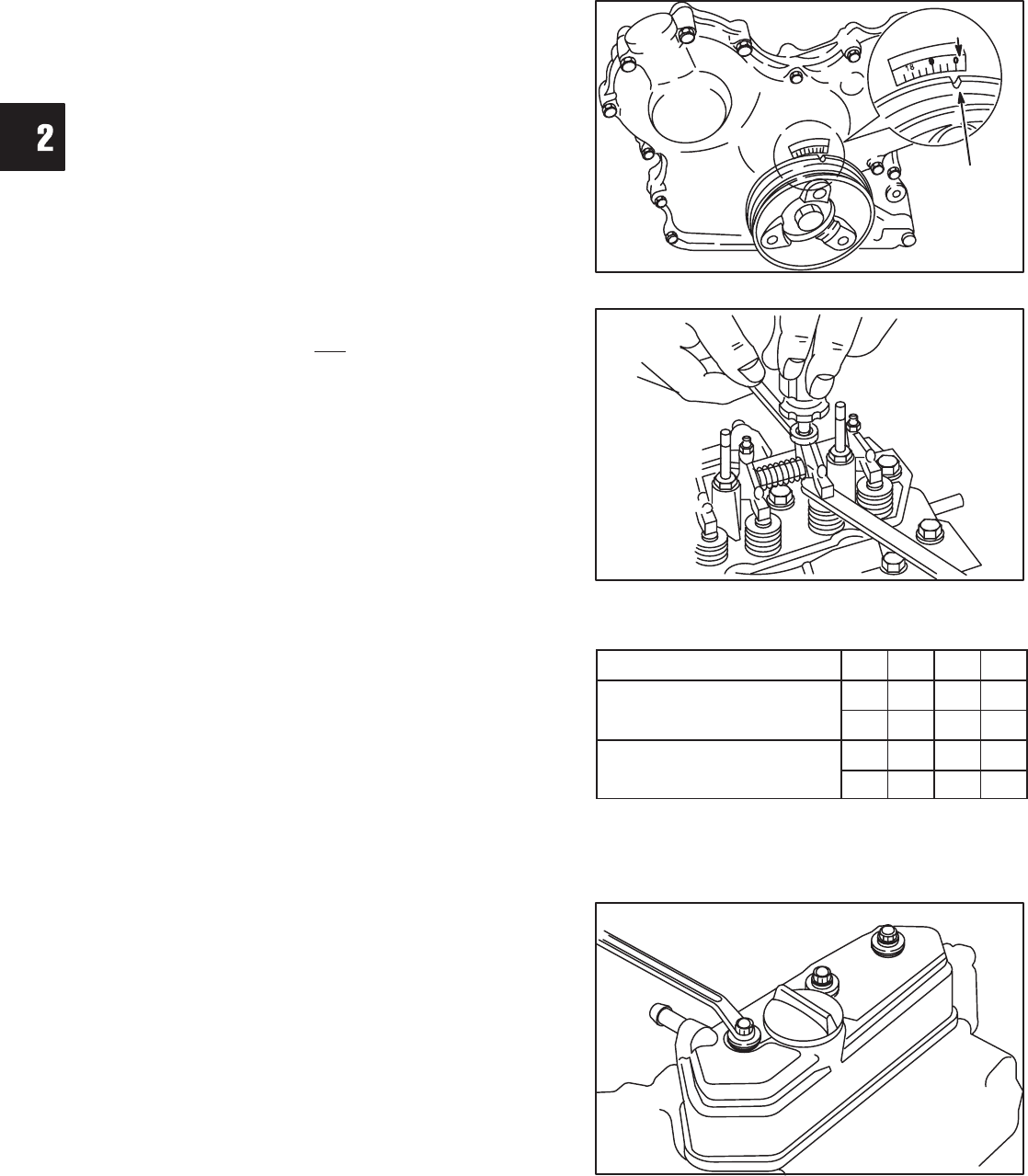

1. Before adjusting valves, make sure that No. 1

cylinder is at TDC – compression stroke, Fig. 42.

Fig. 42 – Set Cylinder No. 1 at TDC

REFERENCE

POINT

TIMING

MARK

a. Adjust valves and check, Fig. 43.

Valve Clearance (cold) IN and EX 0.20 mm (0.008 in.)

b. Torque adjusting screws and jam nuts to 11.0

Nm (95 in. lbs.).

Fig. 43 – Adjust Valve Clearances

With No. 1 piston at TDC of compression stroke, check

and adjust valve clearances for cylinders shown in

chart at right.

Rotate crankshaft one complete turn (360°)"clockwise

to check and adjust remaining valves.

Piston Position Cylinder 1 2 3

No. 1 piston at TDC, of

IN

l l

No

.

1 piston at TDC

,

of

compression stroke

EX

l l

Rotate Crankshaft 360°

IN

l

Rotate Crankshaft 360

clockwise

EX

l

2. Install valve cover with new rubber seal, Fig. 44.

a. Torque cover nuts to 7.0 Nm (50 in. lbs.).

NOTE: Make sure rubber seal is in groove in

valve cover.

Fig. 44 – Install Valve Cover