3

3

TIMING GEARS AND GEAR CASE

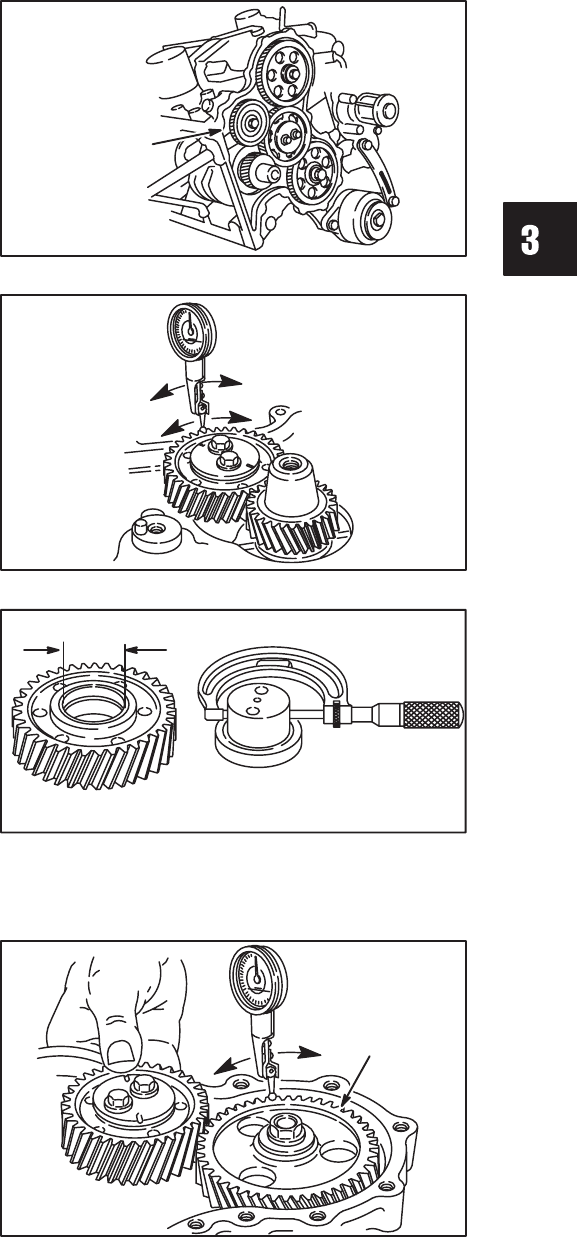

6. Remove oil pump drive gear, Fig. 5.

a. Check oil pump drive gear for damaged teeth.

Fig. 5 – Removing Oil Pump Gear

OIL

PUMP

GEAR

CHECKING GEARS

Inspect gear teeth for wear or damage.

CHECK GEARS IN SEQUENCE SHOWN.

1. Check gear backlash between idler gear and

crankshaft gear using dial indicator as shown in

Fig. 6.

a. Set tip of indicator on gear tooth, then rock

idler gear back and forth noting indicator

reading.

NOTE: Crankshaft must not turn while checking.

Fig. 6 – Checking Idler Gear Backlash

IDLER

GEAR

CRANKSHAFT

GEAR

2. If backlash exceeds 0.2 mm (.008”) check idler

gear bearing and shaft for wear, Fig. 7.

Reject Dimension: Idler Gear ID –

34.17 mm (1.345”)

Idler Gear Shaft OD –

33.91 mm (1.335”)

a. If idler gear bearing and shaft are within

specification, replace with new idler gear and

recheck.

b. If backlash exceeds 0.2 mm (.008”) with NEW

idler gear, crankshaft gear is worn.

NOTE: If crankshaft gear is worn the crankshaft

must be replaced.

Fig. 7 – Checking Idler Gear And Shaft

IDLER

GEAR

IDLER

GEAR

SHAFT

3. Hold idler gear as shown and check gear backlash

between camshaft timing gear and idler gear using

dial indicator, Fig. 8.

Camshaft timing gear backlash must not exceed

0.2 mm (.008”).

NOTE: Idler gear must not turn while checking.

Fig. 8 – Checking Camshaft Timing Gear Backlash

CAMSHAFT

TIMING

GEAR

IDLER

GEAR