10

8

INJECTORS

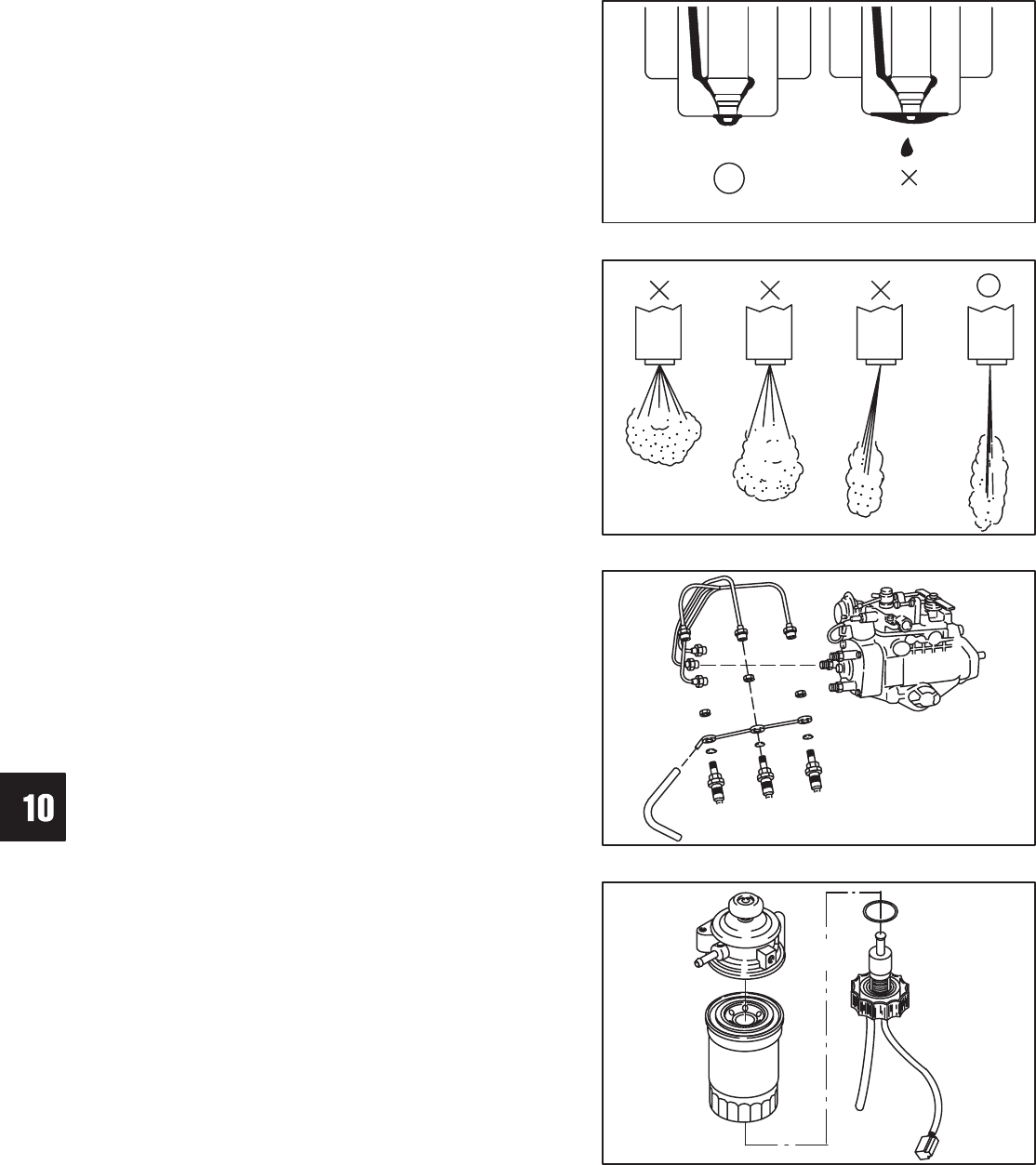

3. Check injector for leakage, Fig. 16.

Maintain injector pressure at approximately 120 Bar

(1707 psi), for about 10 seconds. Make sure there is no

leakage from nozzle or retaining nut area.

Fig. 16 – Checking Leakage

4. Check spray pattern of nozzle, Fig. 17.

Operate tester handle rapidly while observing pattern.

Spray pattern should be uniform and centered under

nozzle.

NOTE: A buzzing or chattering sound should also

occur while operating handle. Nozzle

should not drip between pump strokes.

Fig. 17 – Checking Spray Pattern

Install Injectors

Install injectors and fuel return line with new gaskets,

Fig. 18. Install fuel delivery lines.

a. Torque injectors to 61.0 Nm (45 ft. lbs.).

b. Torque fuel return line to 27.0 Nm (20 ft. lbs.).

c. Torque fuel delivery lines to 25.0 Nm

(220 in. lbs.).

Fig. 18 – Installing Injectors

FUEL FILTER – GENERAL

The fuel filter consists of a replaceable cartridge type

filter with a water level sensor and priming pump,

Fig. 19.

Replace fuel filter cartridge every 800 hours of engine

operation.

The water collector contains a float type sensor that

activates a warning lamp when it collects a minimum of

80 cc’s (2.5 fl. oz.) of water.

Fig. 19 – Fuel Filter

DRAIN PLUG

FILTER

O-RING

FLOATVENT PLUG

PRIMER

BUTTON