9

2

CYLINDER BLOCK ASSEMBLY

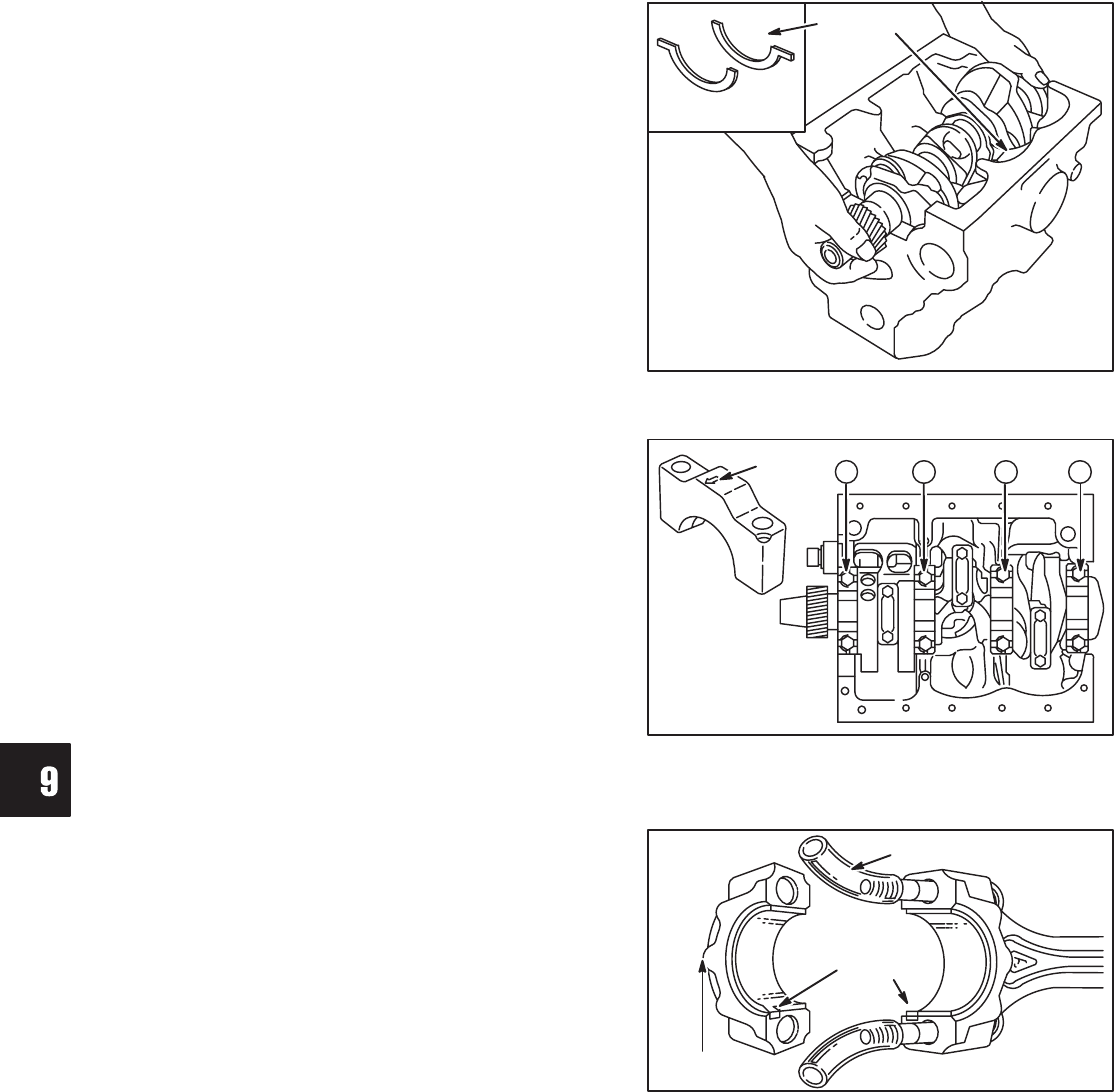

3. Install crankshaft with gear facing front of cylinder

block, Fig. 3. Take care not to damage journals or

bearings.

a. Install crankshaft shims on #3 main bearing

web with grooves facing out.

b. Lubricate journals with engine oil.

Fig. 3 – Installing Crankshaft

INSTALL

SHIMS

#3 MAIN

BEARING

4. Install main bearing caps, Fig. 4. Lubricate

threads of screws with engine oil.

a. Install bearing caps in their respective

positions with arrows facing front.

b. Starting with #3 bearing cap, torque bearing

caps one at a time in sequence shown to 58.0

Nm (43 ft. lbs.).

c. Recheck crankshaft end play.

Crankshaft End Play: 0.025-0.24 mm

(0.0008-0.0094”)

NOTE: After torquing bearing cap, make sure

crankshaft rotates freely before pro-

ceeding to next bearing cap.

Fig. 4 – Installing Main Bearing Caps

ARROW

FRONT

FRONT

#1

#2

#3

#4

3

412

INSTALL PISTONS AND

CONNECTING RODS

1. Install connecting rod bearings, Fig. 5. Be sure

tang on bearing is seated in notch in connecting

rod and cap.

a. Install a piece of vinyl tubing over each

connecting rod screw to prevent damage to

screw threads or crankpin when installing

piston and connecting rod.

Fig. 5 – Installing Connecting Rod Bearings

NOTCH

VINYL TUBING

ID MARK