Workman MDE Transaxle and BrakesPage 4 -- 7

Removal (Fig. 1)

1. Park vehicle on a level surface, turn on/off switch

OFF and remove key from the on/off switch.

WARNING

Before jacking up the vehicle, review and follow

Jacking Instructions in Operator’s Manual and

Chapter 1 -- Safety.

2. Chock wheels notbeing jacked up.Lift rearwheel off

theground usingajackand placeappropriatejack stand

beneath the rear frame to support vehicle.

NOTE: To remove brake drum, it may be necessary to

loosen parking brake cable adjustment or remove park-

ing brake cable from brake actuator lever.

3. Remove five (5)lug nuts, wheelassembly and brake

drum from the wheel hub.

4. Remove cotter pin and flange nut that secure wheel

hub (item 7) to the transaxle shaft.

5. Remove wheel hub from transaxle.

6. If necessary, use press to remove wheel studs from

hub.

7. If necessary, remove brake assembly from trans-

axle:

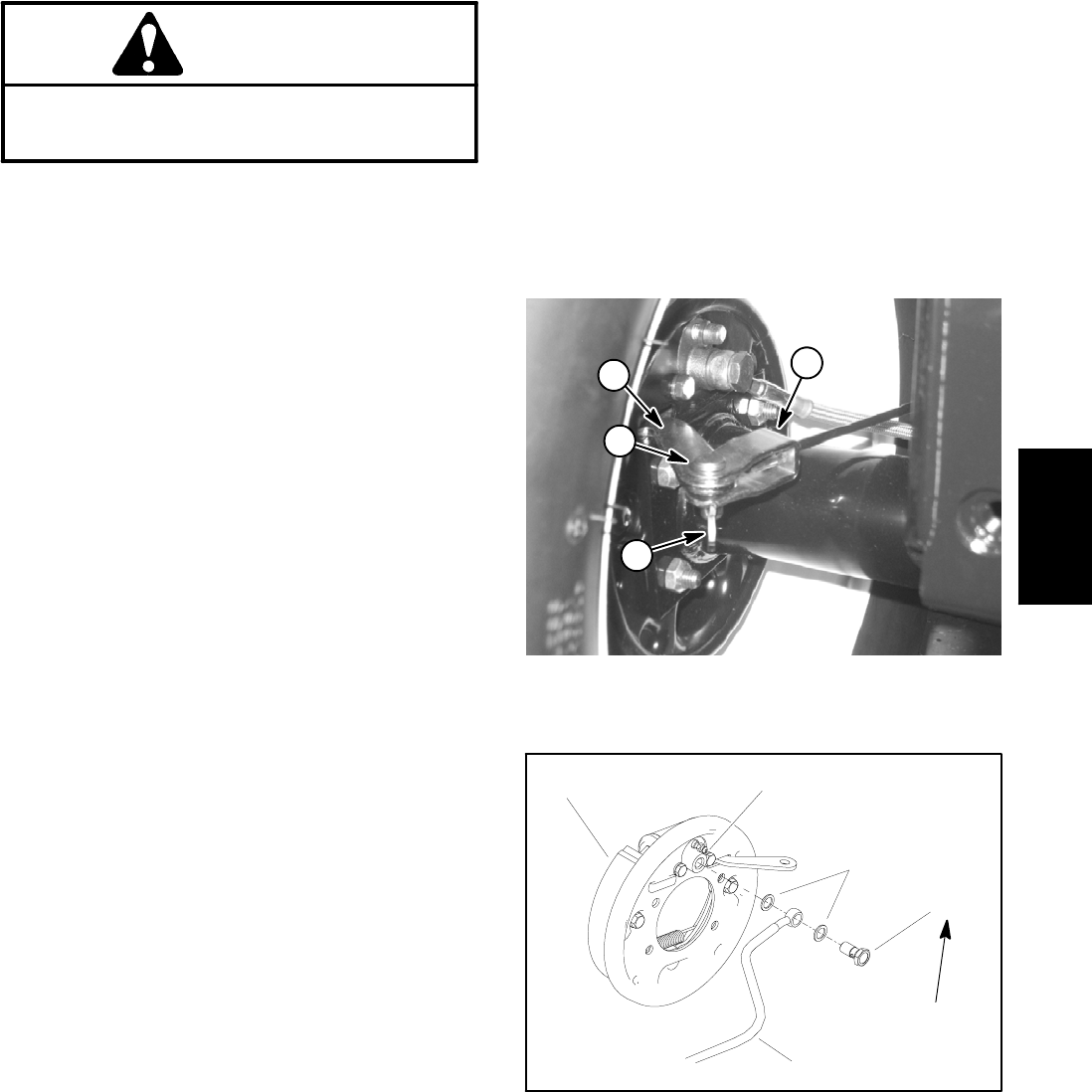

A. Remove cotter pin and clevis pin securing the

parking brake cable bracket to the brake actuator le-

ver (Fig. 2).

B. Clean hydraulic brake line area of rear brake cyl-

inder to prevent contamination. Loosen and discon-

nect hydraulic brake line from wheel cylinder. Plug

brake line and position it away from wheel cylinder.

C. Remove four (4) socket head screws and lock

nuts securing the brake assembly to the transaxle.

Remove brake assembly from the transaxle.

Installation (Fig. 1)

IMPORTANT:The parking brake actuation levers

should be positioned above the transaxle mount.

When positioned correctly, the levers will point to-

ward the rear of the vehicle (Fig. 2).

1. If brake assembly was removed from axle, install

brake assembly to transaxle.

A. Secure brake assembly to the transaxle with four

(4) socket head screws and lock nuts. Torque lock

nuts from 26 to 30 ft--lb (34 to 41 N--m).

B. Position and securehydraulic brake line to wheel

cylinder (Fig. 3). Torque banjo bolt from 15 to 21 ft--

lb(21to28N--m).

C. Secure parking brake cable bracket to the brake

actuator lever with clevis pin and cotter pin (Fig. 2).

2. If wheel studs were removed from wheel hub, use

press to install wheel studs into hub. Make sure to fully

press studs into hub.

3. Slide wheel hub onto transaxle shaft. Install flange

nut to secure wheel hub to the transaxle shaft. Torque

nutfrom125 to140ft--lb(170 to190N--m).Installcotter

pin.

4. Slide brake drum onto wheel hub.

1. Cotter pin

2. Clevis pin

3. Brake cable bracket

4. Brake actuator lever

Figure 2

2

3

1

4

1. Brake assembly

2. Wheel cylinder

3. Banjo washer

4. Banjo bolt

5. Brake line

Figure 3

5

4

1

2

3

15 to 21 ft--lb

(21to28N--m)

Transaxle and

Brakes