Workman MDE

Page 3 -- 33

Electrical System

Traction Motor Brushes

The traction motor in the Workman MDE uses eight (8)

brushes. Traction motor brushes should be inspected

every 500 hours of operation or annually.

Inspection

1. Make sure that on/off switch is OFF. Raise and latch

cargo box to allow access to traction motor.

2. Open the battery circuit by carefully removing one of

the battery cables (see Opening Battery Circuit in the

General Information section of this chapter).

3. Unlatch headband of traction motor and reposition

headband to allow inspection of abrush at the top of the

motor.

4. If end ofbrush is even with the brushholder (Figs. 47

and 49), brushes should be r emoved from motor for in-

spection andmeasurement (seeTraction MotorService

in this section).

5. In most instances, wear of all traction motor brushes

should be similar to wear found onthe top brushes. If in-

spection of remaining brushes is needed or if brushes

require replacement, traction motor should be removed

from vehicle ( see Traction Motor and Traction Motor

Service in this s ection).

6. If vehicle is often operated in severely dirty environ-

ments, brush should be removed frommotor to allow in-

spection of mating surface of brush (Fig. 48). If brush

surface is rough, pitted, arced or scored, additional

brush and/or motor inspection should be completed

(see Traction Motor and Traction Motor Service in this

section).

7. Visually inspect commutator surface of motor arma-

ture. If commutator surface is rough, pitted, arced or

scored, additional motor inspection should be com-

pleted (see Traction Motor and Traction Motor Service

in this section).

8. After brush inspection, make sure brush is correctly

installed in brush holder and tensioned by spring. Refit

headband to traction motor and latch headband.

9. Carefully connect removed battery cable to battery

terminals. Install lock washer and nut on battery termi-

nals. Torque nuts from 115 to 125 in--lb (13.0 to 14.1

N--m).

10.Lower and secure cargo box.

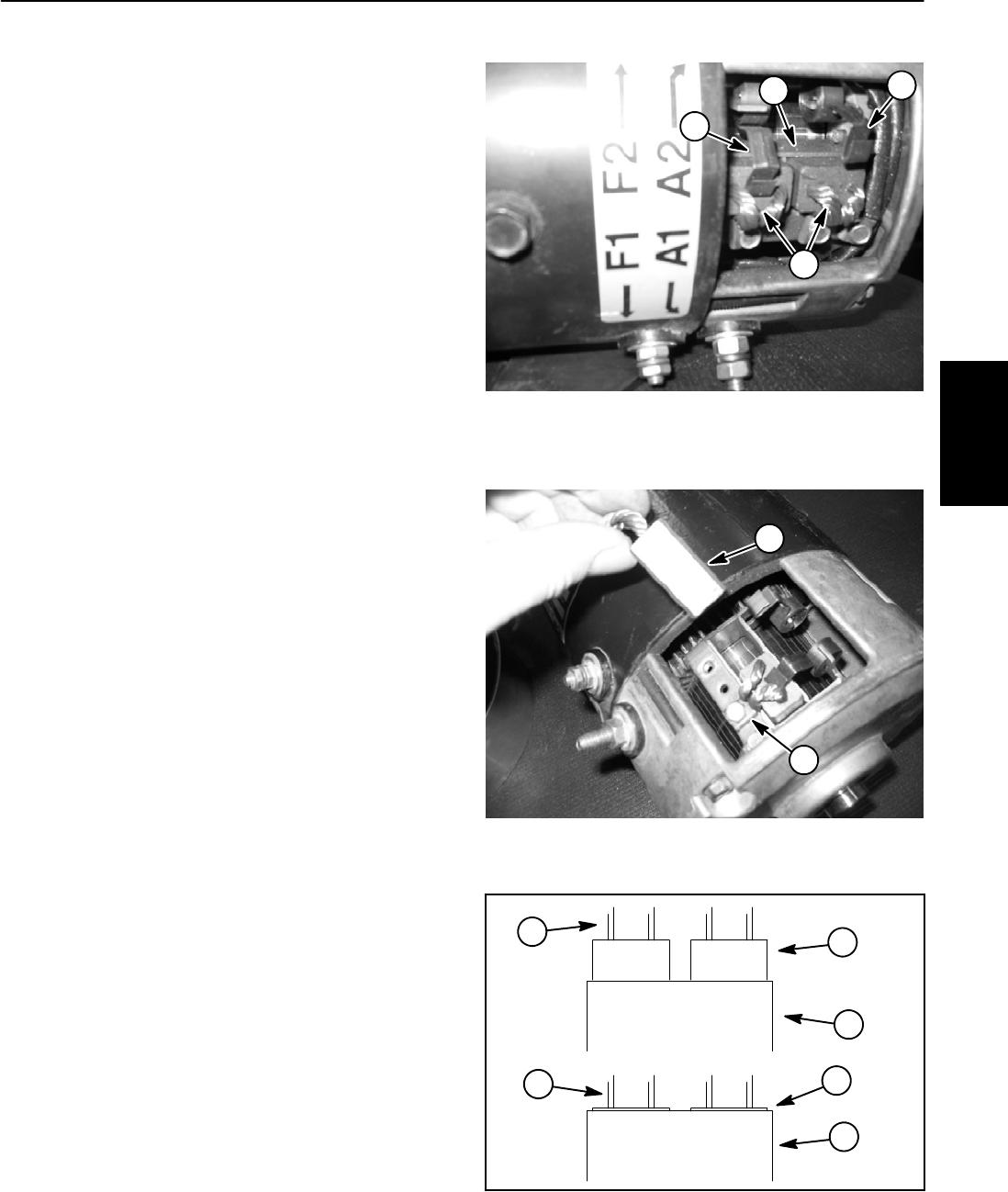

1. Brush

2. Brush holder

3. Brush spring (tensioned)

4. Brush spring (released)

Figure 47

2

1

3

4

1. Removed brush 2. Cap screw

Figure 48

1

2

1. Brush holder (side view)

2. Normal brush

3. Worn brush

4. Brush shunt wire

Figure 49

1

2

3

4

4

1

Electrical

System