Workman MDE

Page 3 -- 38

Electrical System

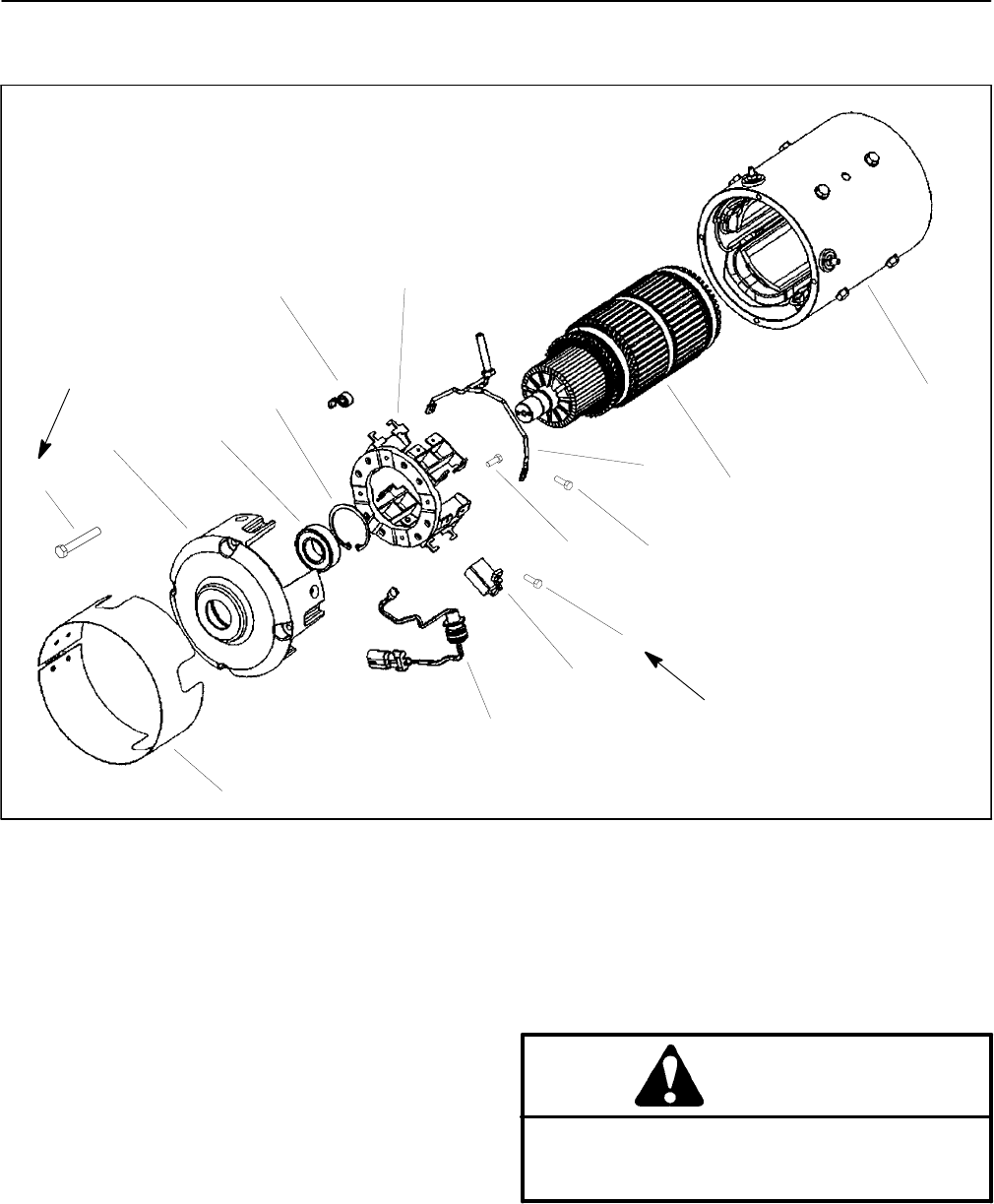

Traction Motor Service

1. Frame and field assembly

2. Armature

3. Brush lead (2 used)

4. Cap screw (2 used per brush lead)

5. Cap screw (4 used)

6. Cap screw (8 used)

7. Brush (8 used)

8. High temperature sensor

9. Headband

10. Bolt (4 used)

11. Commutator end head

12. Bearing

13. Retaining ring

14. Brush spring (8 used)

15. Brush box

Figure 56

3

4

5

8

6

7

9

1

10

12

2

11

13

14

18 to 22 in--lb

(2.0 to 2.5 N--m)

120 to 140 in--lb

(13.6 to 15.8 N--m)

15

Disassembly (Fig. 56)

1. Unlatch and slide headband from traction motor.

2. Pull back the brush springs and latch them in the

open position on the spring holders. Slide brushes from

the brush holders.

3. Use an arbor press or a bearing puller to remove the

armature from thecommutator end head andframe and

field assembly (Fig. 57).

4. Remove four (4) bolts that secure the commutator

endhead tothe frameand fieldassembly.Remove com-

mutator end head from frame and field assembly.

5. Remove the retaining ring and press bearing from

the commutator end head. Discard the bearing.

CAUTION

When using compressed air for cleaning motor

components, follow all safety instructions, in-

cluding wearing eye and respiratory protection.

6. Carefully blowout anyaccumulated carbon dustand

dirt from the commutator end head and the frame and

field assembly using clean, oil free, compressed air.