Workman MDE

Page 3 -- 29

Electrical System

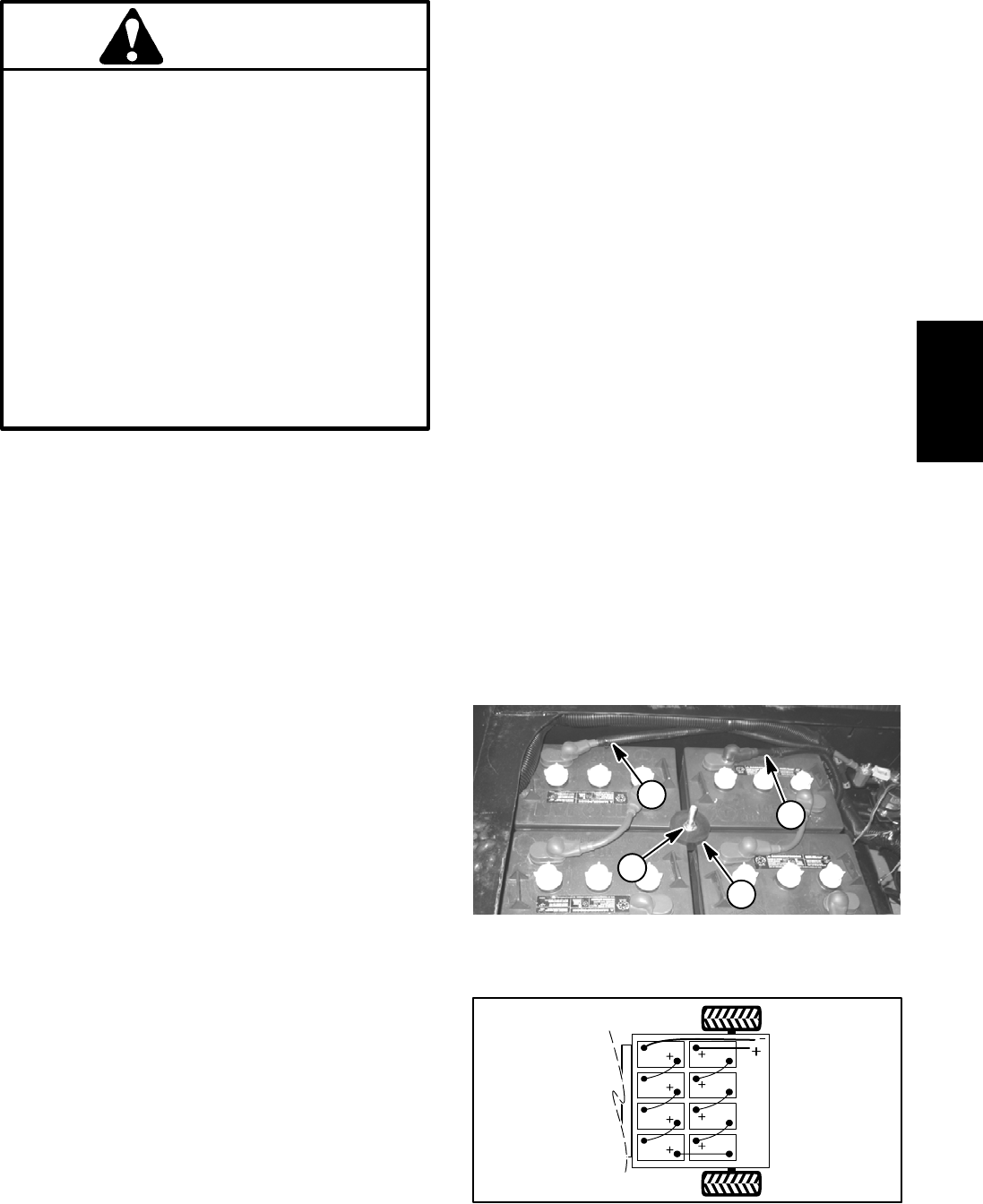

Battery Removal (Fig. 42)

WARNING

POTENTIAL HAZARD:

The battery terminals, metal tools and metal ve-

hicle parts could short together.

WHAT CAN HAPPEN:

Sparks can cause battery gasses to explode.

Damaged cables could short against metal ve-

hicle parts and cause sparks.

HOW TO AVOID THE HAZARD:

When removing or installing the batteries, do

notallow thebattery terminalsto shortagainst

metal parts of the vehicle.

Donot allowmetal toolsor metalvehicle partsto

short between the battery terminals or battery

cables.

Always keep the battery retainers in place to

protect and secure the batteries.

IMPORTANT: B e careful to not damage terminal

posts or cable connectors when removing the bat-

tery cables.

1. Position vehicle on a level surface, set parking

brake, turn on/off switch OFF and remove key.

2. Raise cargo box and secure with prop rod.

3. Open the battery circuit by carefully removing one of

the battery cables (see Opening Battery Circuit in the

General Information section of this chapter).

4. Once initial cable has been removed from vehicle,

disconnect and remove remaining battery cables from

all battery terminals.

5. Remove flange nuts (item 11) and battery retainers

(item 10) used to secure batteries to vehicle (Fig. 43).

6. Make sure that all battery filler caps are on tightly.

IMPORTANT: W hen removing batteries from ve-

hicle, do not lift batteries using battery terminals as

lift points: battery damage may occur.

7. Using case loops on battery tops as lifting points, re-

move batteries from vehicle.

Battery Installation (Fig. 42)

IMPORTANT: To prevent possible electrical prob -

lems, install only fully charged batteries.

1. Make sure vehicle on/off switch and all accessories

are OFF. Raise cargo box and secure with prop rod.

2. Make sure the battery supports are clean and re-

painted if necessary. Make sure cables, terminals, rods

and hold down retainers are in good condition.

IMPORTANT: When installing batteriesinto vehicle,

do not lift batteries using battery terminals as lift

points: battery damage may occur.

3. Using case loops on batterytops as lifting points, set

batteries on the battery supports with battery posts

properly orientated (Fig. 44). Make sure that battery

rods are positioned to allow installation of retainers.

4. Install two (2) battery retainers and nuts to secure

batteries to vehicle (Fig. 43). Torque nuts from 115 to

125 in--lb (13.0 to 14.1 N --m).

5. Install all but one of the battery cables used to con-

nect battery pack including the positive (red) cable and

negative (black) cablefrom vehicle (Figures 42and 44).

Make sure that cables are connected to c orrect battery

terminal noting battery polarity. Install lock washer and

nut on each battery terminal. Torque nuts from 115 to

125 in--lb (13.0 to 14.1 N --m) to secure cables.

6. Connect final battery cable to battery terminals.

Install lock washer and nut on battery terminals. Torque

nuts from 115 to 125 in--lb (13.0 to 14.1 N--m).

7. Apply Toro battery terminal protector (see Special

Tools) to all battery posts and cable connectors to re-

duce corrosion after connections are made. Make sure

that terminal boots are positioned over all connections.

8. Lower and secure cargo box.

1. Negative cable to vehicle

2. Positive cable to vehicle

3. Flange nut

4. Battery retainer

Figure 43

1

2

3

4

Figure 44

A

4

Electrical

System