8-1

CHASSIS

TUNING

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

<Requirement for selection of secondary gear

reduction ratio>

• It is generally said that the secondary gear ra-

tio should be reduced for a longer straight por-

tion of a speed course and should be

increased for a course with many corners. Ac-

tually, however, as the speed depends on the

ground condition of the day of the race, be

sure to run through the circuit to set the ma-

chine suitable for the entire course.

• In actuality, it is very difficult to achieve set-

tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the race

result. In such a case, run through the entire

course while making notes of lap times to find

the best balance; then, determine the second-

ary reduction ratio.

• If a course has a long straight portion where a

machine can run at maximum speed, the ma-

chine is generally set such that it can develop

its maximum revolutions toward the end of the

straight line, with care taken to avoid the en-

gine over-revving.

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider's settings from the beginning but

choose your own setting according to the level

of your riding technique.

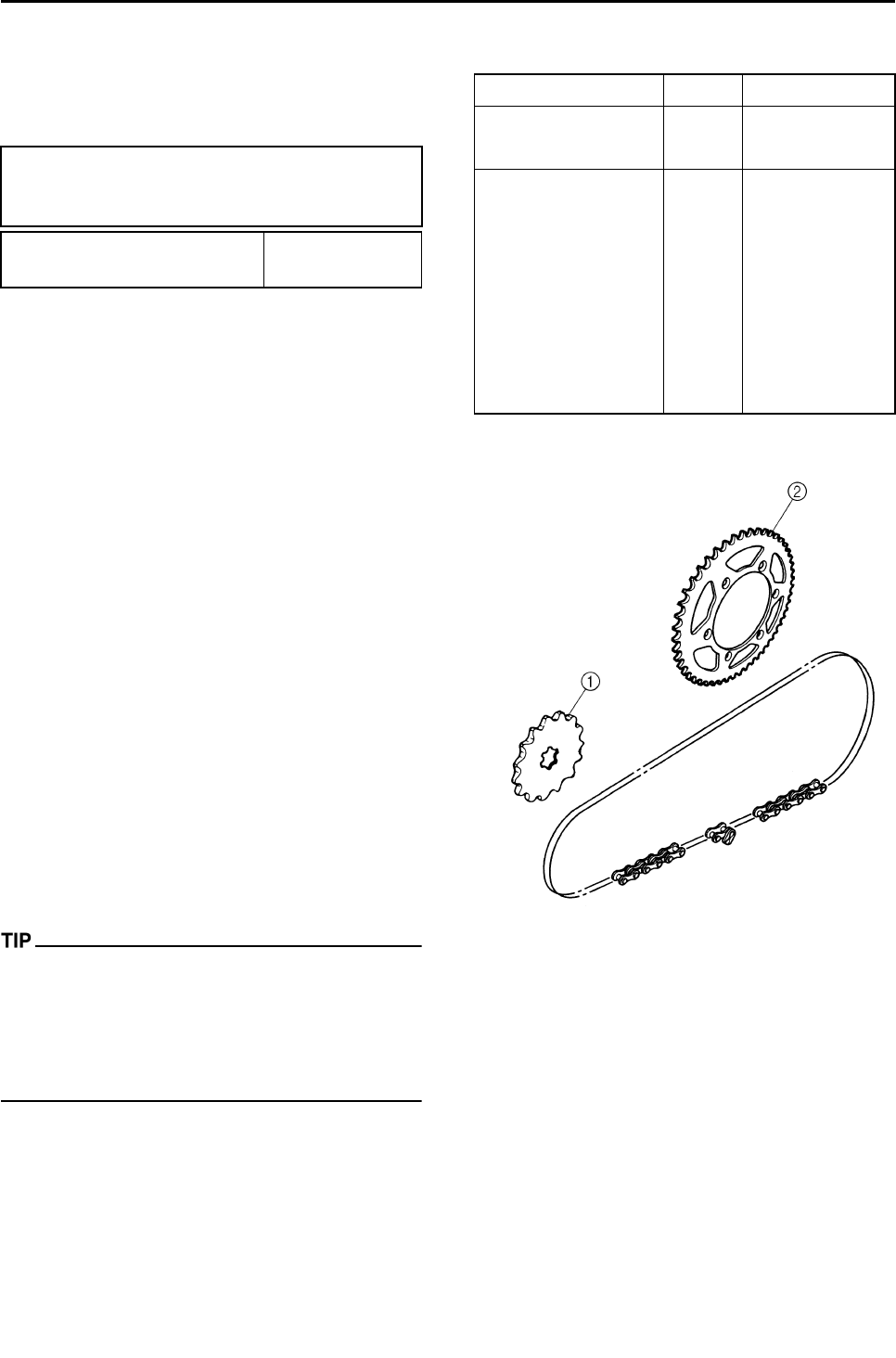

DRIVE AND REAR WHEEL SPROCKETS

SETTING PARTS

Secondary reduction ratio = Number of

rear wheel sprocket teeth/Number of

drive sprocket teeth

Standard secondary re-

duction ratio

48/13 (3.692)

* 49/13 (3.769)

* Except for USA and CDN

Part name Size Part number

Drive sprocket "1"

(STD) 13T 9383E-13233

Rear wheel

sprocket "2"

47T 17D-25447-50

(STD) 48T 17D-25448-50

* (STD) 49T 17D-25449-50

50T 17D-25450-50

51T 17D-25451-50

52T 17D-25452-50

* Except for USA and CDN