4-27

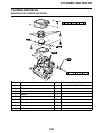

VALVES AND VALVE SPRINGS

b. Apply molybdenum disulfide oil to the valve

stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and valve

seat are evenly polished, then clean off all of

the compound.

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth be-

tween your hands.

e. Apply a fine lapping compound to the valve

face and repeat the above steps.

After every lapping operation be sure to clean

off all of the compound from the valve face and

valve seat.

f. Apply Mechanic's blueing dye (Dykem) to

the valve face.

g. Install the valve into the cylinder head.

h. Press the valve through the valve guide and

onto the valve seat to make a clear pattern.

i. Measure the valve seat width again. If the

valve seat width is out of specification,

reface and relap the valve seat.

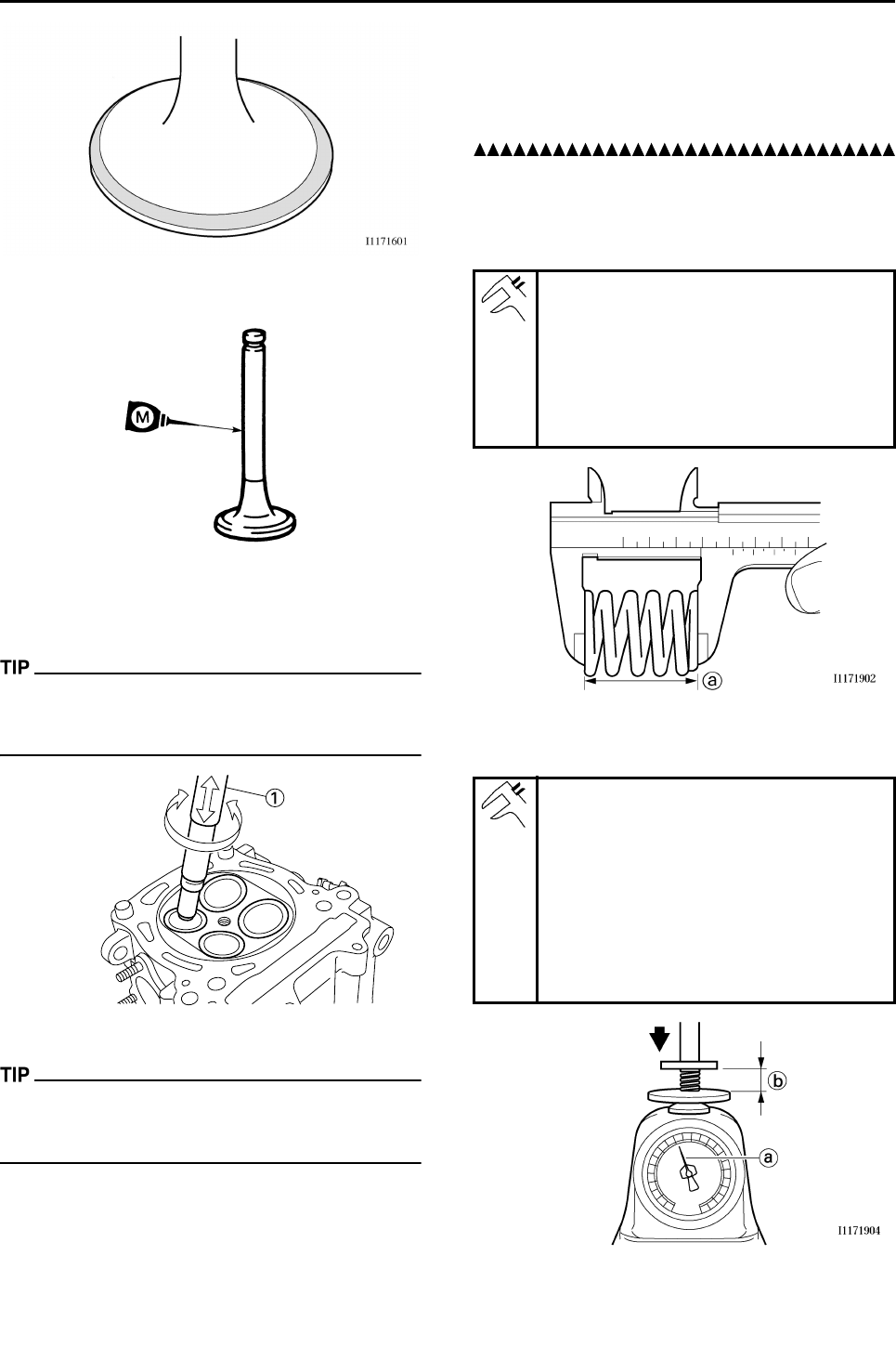

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification → Replace.

2. Measure:

• Compressed spring force "a"

Out of specification → Replace.

b. Installed length

Free length (valve spring):

Intake:

40.76 mm (1.60 in)

<Limit>: 39.76 mm (1.57 in)

Exhaust:

37.01 mm (1.46 in)

<Limit>: 36.01 mm (1.42 in)

Compressed spring force:

Intake:

178–204 N at 34.78 mm (18.2–20.8

kg at 34.78 mm, 40.01–45.86 lb at

1.37 in)

Exhaust:

124–142 N at 30.83 mm (12.6–14.5

kg at 30.83 mm, 27.88–31.92 lb at

1.21 in)