4-22

CYLINDER HEAD

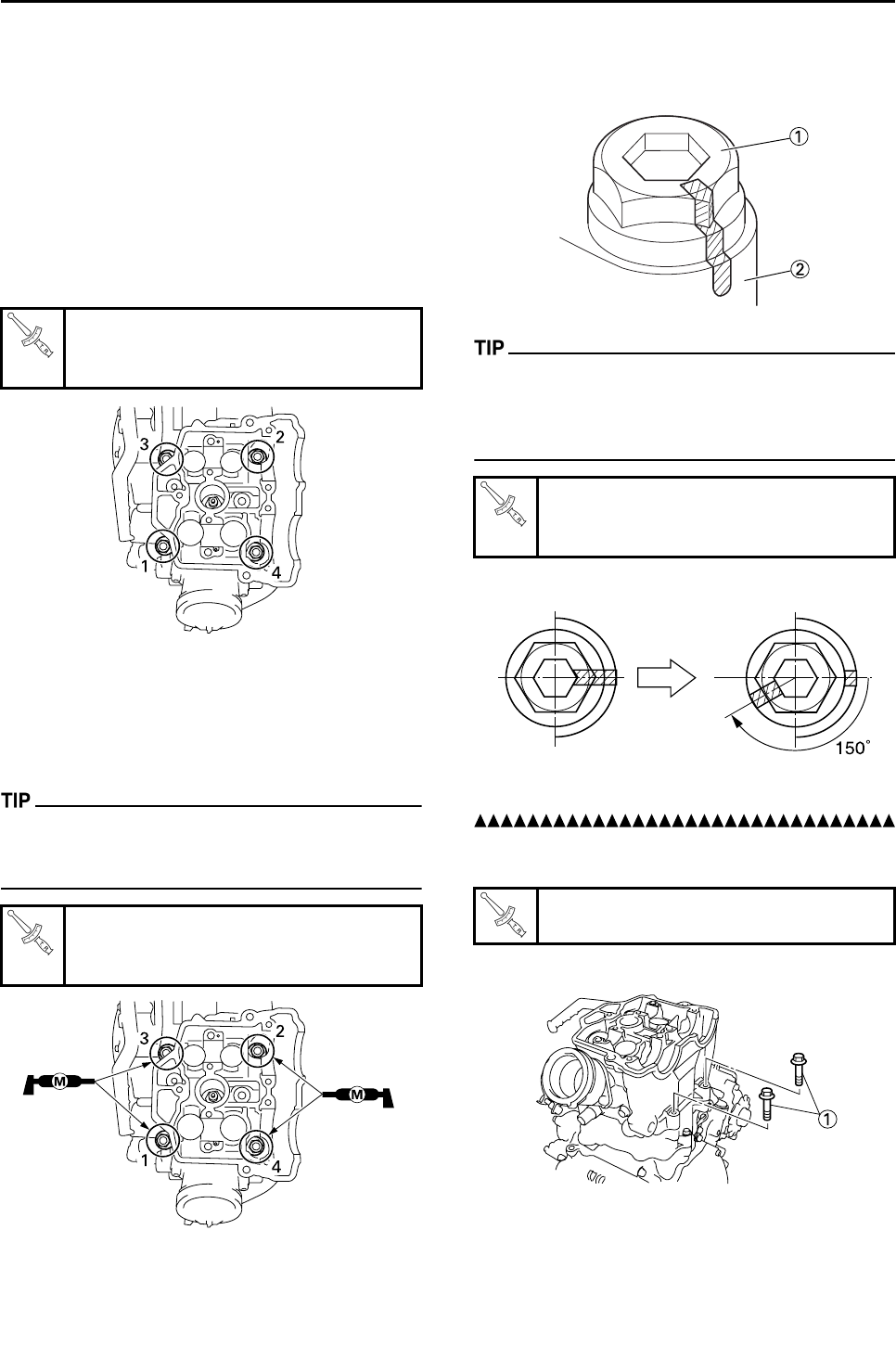

a. Wash the threads and contact surfaces of

the bolts, the contact surfaces of the plain

washers, the contact surface of the cylinder

head, and the threads of the crankcase.

b. Apply the molybdenum disulfide grease on

the threads and contact surfaces of the bolts

and on both contact surfaces of the plain

washers.

c. Install the plain washers and bolts.

d. Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown.

e. Remove the bolts.

f. Again apply the molybdenum disulfide

grease on the threads and contact surfaces

of the bolts and on both contact surfaces of

the plain washers.

g. Retighten the bolts.

Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

h. Put a mark on the corner "1" of the bolt (cyl-

inder head) and the cylinder head "2" as

shown.

Tighten the bolts two times at specified angles

of 90°and 60° to reach the specified angle of

150° in the proper tightening sequence as

shown.

3. Install:

• Bolt (cylinder head) "1"

Bolts (cylinder head):

1st:

30 Nm (3.0 m•kg, 22 ft•lb)

Bolts (cylinder head):

2nd:

20 Nm (2.0 m•kg, 14 ft•lb)

Bolts (cylinder head):

Final:

Specified angle 150°

Bolt (cylinder head):

10 Nm (1.0 m•kg, 7.2 ft•lb)