7-45

ELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensor

Refer to "REMOVING THE CYLINDER

HEAD" section in the CHAPTER 4.

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.

2. Check:

• Coolant temperature sensor resistance

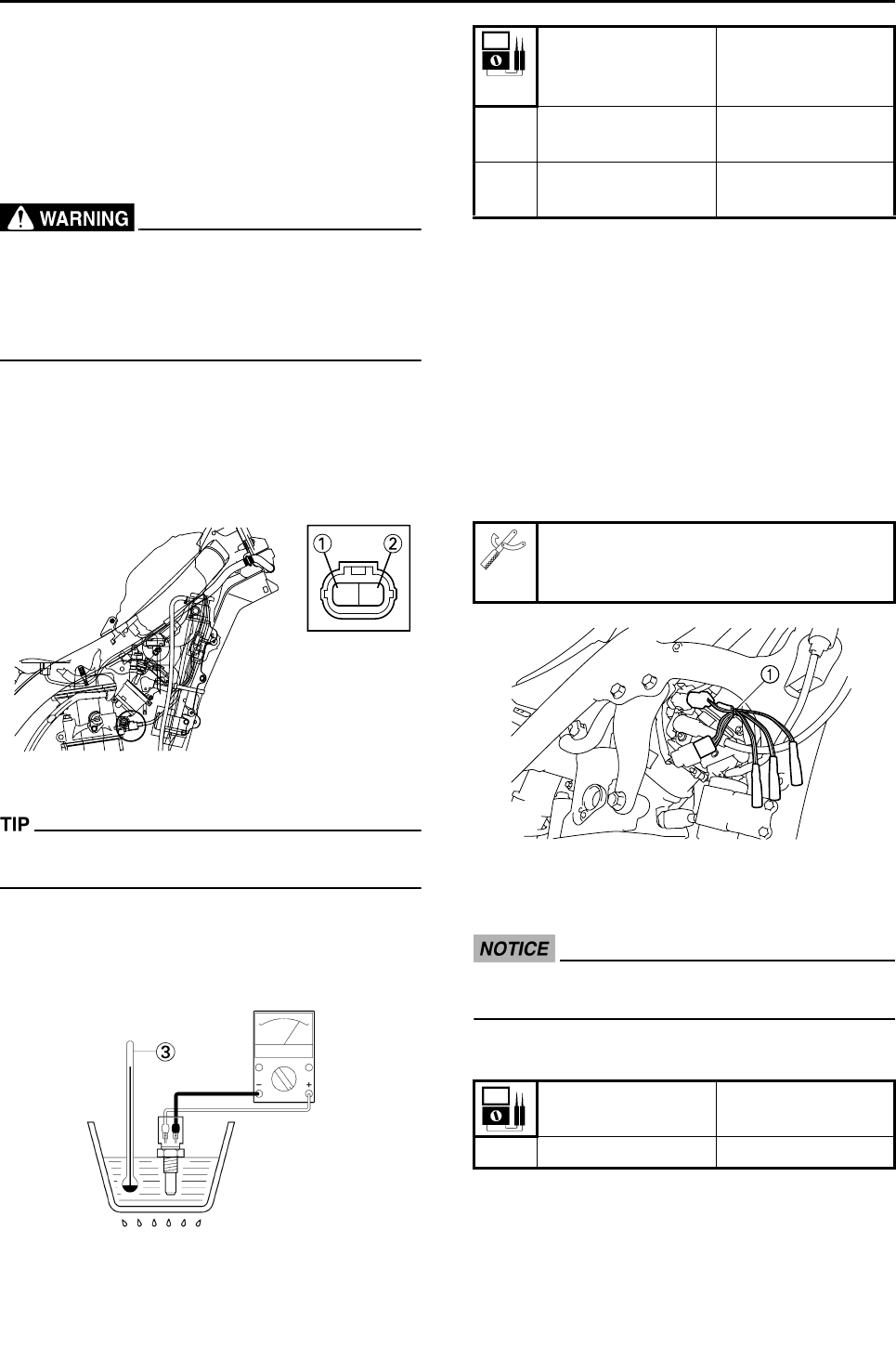

3. Connect:

• Tester

Tester (+) lead → Brown lead "1"

Tester (-) lead → Black/Blue lead "2"

4. Immerse the coolant temperature sensor in

a container filled with coolant.

Make sure the coolant temperature sensor ter-

minals do not get wet.

5. Place a thermometer "3" in the coolant.

6. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

Out of specification → Replace.

CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

2. Connect:

• Test harness S–pressure sensor (3P) "1"

• Tester

Tester (+) lead → Pink/White lead (wire har-

ness color)

Tester (-) lead → Black/Blue lead (wire har-

ness color)

3. Connect the FI diagnostic tool sub-wire har-

ness to a battery, and then set the switch on

the harness to "ON".

When checking the intake air pressure sen-

sor, do not start the engine.

4. Measure the intake air pressure sensor out-

put voltage.

Out of specification → Replace.

B/L

Br

Coolant tempera-

ture sensor resis-

tance

Tester selector po-

sition

210 — 220 Ω (100

°C, 212 °F)

Ω×100

2.51—2.78 kΩ (20

°C, 68°F)

kΩ×1

Test harness S–pressure sensor

(3P):

YU-03207/90890-03207

Output voltage

Tester selector po-

sition

3.4 — 3.8 V DCV