5B.22

Section 5B

EFI Fuel System

General

Special low permeation high-pressure fuel line with

an SAE 30 R9 rating is required for safe and reliable

operation, due to the higher operating pressure of the

EFI system. If hose replacement is necessary, order

Fuel Line Service Kit Part No. 25 111 37-S (containing

60” of high-pressure hose and 10 Oetiker clamps), or

use only the type of hose specified. Special Oetiker

clamps (Kohler Part No. 24 237 05-S) are used on all

fuel line connections to prevent tampering and safety

hazards with the high fuel pressure. The old clamp

must be cut to open a connection, so replacement is

necessary each time. Oetiker Clamp Pliers (part of EFI

Service Kit, see Section 2) is used to crimp the

replacement clamps.

CAUTION:

Fuel lines between the fuel pump and fuel rail must be made

from SAE 30 R9 fuel line. Standard fuel line (SAE 30 R7)

may only be used between the fuel tank and pump (5/16”

ID) and for the return line from the pressure regulator to

the tank (1/4” ID). All high-pressure fuel line connections

must be secured with Oetiker clamps (Kohler Part No.

24 237 05-S), installed/crimped with the corresponding

pliers.

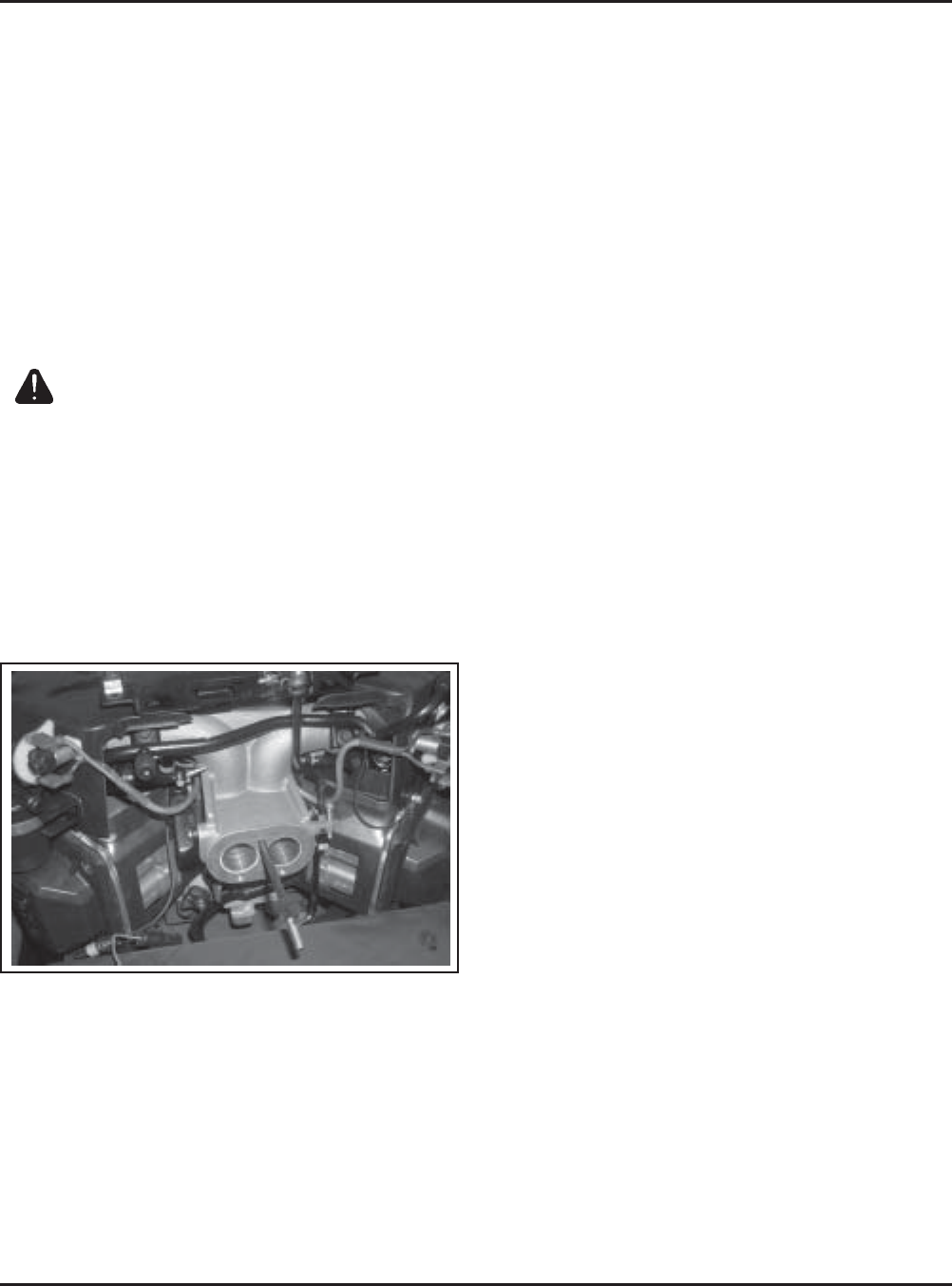

Throttle Body/Intake Manifold Assembly

Service

The throttle body/intake manifold is serviced as an

assembly, with the throttle shaft, TPS, throttle plates,

and idle speed adjusting screw installed. The throttle

shaft rotates on needle bearings (non-serviceable),

capped with rubber seals to prevent air leaks. A

throttle shaft repair kit is available to replace the shaft

if worn or damaged. The appropriate “TPS

Initialization Procedure” must be performed after any

throttle shaft service.

Idle Speed Adjustment (RPM)

General

The idle speed is the only adjustment that may be

performed on the EFI system. The standard idle speed

setting for EFI engines is 1500 RPM, but certain

applications might require a different setting. Check

the equipment manufacturer’s recommendation.

For starting and warm up, the ECU will adjust the fuel

and ignition timing, based upon ambient temperature,

engine temperature, and loads present. In cold

conditions, the idle speed will probably be higher than

normal for a few moments. Under other conditions,

the idle speed may actually start lower than normal,

but gradually increase to the established setting as

operation continues. Do not attempt to circumvent

this warm up period, or readjust the idle speed during

this time. The engine must be completely warmed up,

in closed loop operating mode for accurate idle

adjustment.

Adjustment Procedure

1. Make sure there are no fault codes present in the

ECU memory.

2. Start the engine and allow it to fully warm up

and establish closed looped operation

(approximately 5-10 min.).

3. Place the throttle control in the ‘‘idle/slow’’

position and check the idle speed with a

tachometer. Turn the idle speed screw in or out as

required to obtain 1500 RPM, or the idle speed

specified by the equipment manufacturer. See

Figure 5B-33.

4. The idle speed adjustment can affect the high idle

speed setting. Move the throttle control to the full

throttle position and check the high idle speed.

Adjust as necessary to 3750 RPM, or the speed

specified by the equipment manufacturer.

Figure 5B-32. Upper Throttle Body/Intake Manifold

Details.

General

The EFI engines have no carburetor, so the throttle

function (regulate incoming combustion airflow) is

incorporated in the intake manifold assembly. The

manifold consists of a one-piece aluminum casting

which also provides mounting for the fuel injectors,

throttle position sensor, fuel rail, air baffle, idle speed

screw, and air cleaner assembly.