5B.15

Section 5B

EFI Fuel System

5B

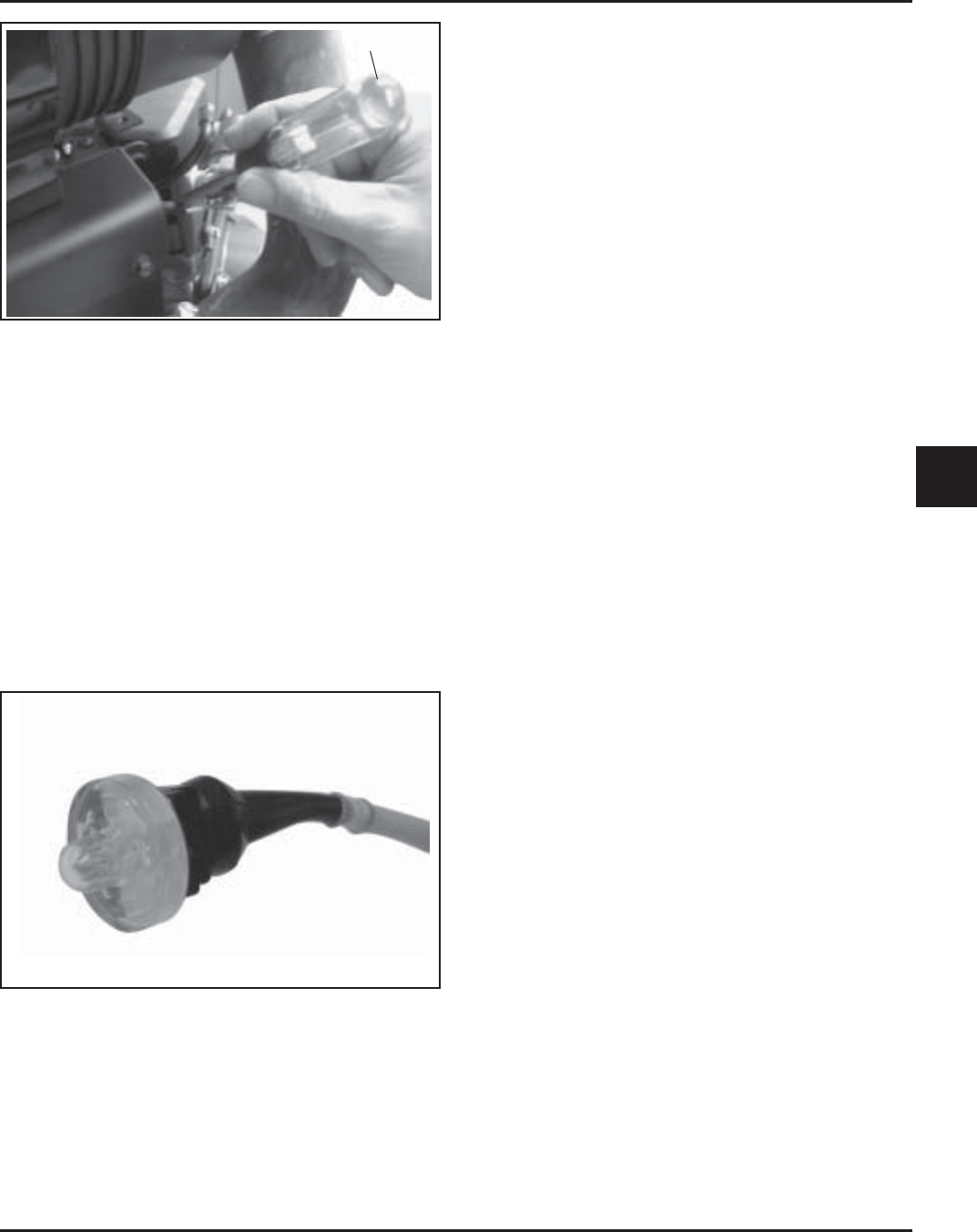

Figure 5B-18. Volt Noid Light.

1. Disconnect the electrical connector from both

injectors. Plug a 12 volt noid light (part of EFI

Service Kit, see Section 2) into one connector.

2. Make sure all safety switch requirements are met.

Crank the engine and check for flashing of the

test light. Repeat test at other connector.

a. If flashing occurs, use an ohmmeter (Rx1

scale) and check the resistance of each

injector across the two terminals. Proper

resistance is 12-20

ΩΩ

ΩΩ

Ω. If injector resistance is

correct, check whether the connector and

injector terminals are making a good

connection. If the resistance is not correct,

replace the injector following steps 1-8 and

13-16 below.

b. If no flashing occurs, reattach the connectors

to both injectors. Disconnect the main harness

connector from the ECU and the connector

from the relay. Set the ohmmeter to the Rx1

scale and check the injector circuit resistance

as follows:

“24 Pin” (MSE 1.0) Plastic-Cased ECU:

Check the resistance between relay terminal

#87 and pin #16 in the main connector. Then

check the resistance between relay terminal

#87 and pin #17. Resistance should be 4-15

ΩΩ

ΩΩ

Ω

for each circuit.

“32 Pin” (MSE 1.1) Plastic-Cased ECU:

Check the resistance between relay terminal

#87 and pin #14 in the main connector. Then

check the resistance between relay terminal

#87 and pin #15. Resistance should be

4-15

ΩΩ

ΩΩ

Ω for each circuit.

Check all electrical connections, connectors, and

wiring harness leads if resistance is incorrect.

Injector leakage is very unlikely, but in those rare

instances it can be internal (past the tip of the valve

needle), or external (weeping around the injector

body). See Figure 5B-19. The loss of system pressure

from the leakage can cause hot restart problems and

longer cranking times. To check for leakage it will be

necessary to loosen or remove the blower housing

which may involve removing the engine from the unit.

Figure 5B-17. Checking Injectors.

3. Disconnect the electrical connector from an

injector and listen for a change in idle

performance (only running on one cylinder) or a

change in injector noise or vibration.

If an injector is not operating, it can indicate either a

bad injector, or a wiring/electrical connection

problem. Check as follows:

NOTE: Do not apply voltage to the fuel injector(s).

Excessive voltage will burn out the

injector(s). Do not ground the injector(s) with

the ignition “on.” Injector(s) will open/turn

on if relay is energized.

Listen Here