5.30

Section 5

Fuel System and Governor

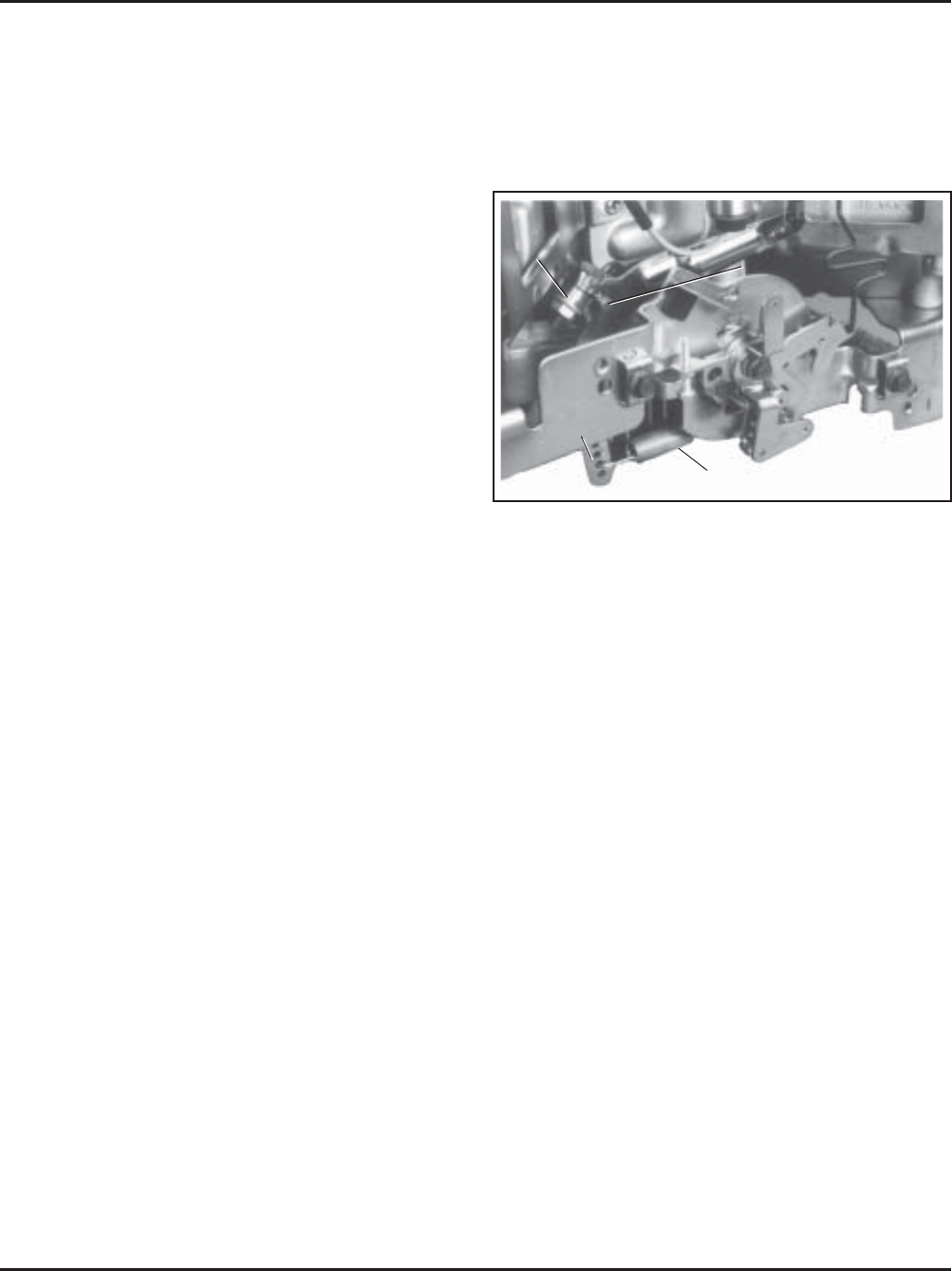

Figure 5-66. Governor Controls and Linkage

(External).

Initial Adjustment

NOTE: EFI engines require a special initial

adjustment procedure, which is covered in

subsection 5B. Refer to “Initial Governor

Adjustment” in that section for setting the

governor on EFI-equipped engines.

Procedure - Carburetor Equipped Engines

Make this adjustment whenever the governor arm is

loosened or removed from the cross shaft. See Figure

5-66 and adjust as follows:

1. Make sure the throttle linkage is connected to the

governor lever and the throttle lever on the

carburetor.

2. Loosen the hex nut holding the governor lever to

the cross shaft.

3. Move the governor lever toward the carburetor

as far as it will move (wide-open throttle) and

hold in position.

4. Insert a nail into the hole in the end of the cross

shaft and rotate the shaft counterclockwise as far

as it will turn, then tighten the hex nut securely.

Adjustments

General

The governed speed setting is determined by the

position of the throttle control. It can be variable or

constant, depending on the engine application.

Governor

General

The engine is equipped with a centrifugal flyweight

mechanical governor. It is designed to hold the engine

speed constant under changing load conditions. The

governor gear/flyweight mechanism is mounted

inside the crankcase on the oil pan, and is driven off

the gear on the camshaft. The governor works as

follows:

• Centrifugal force acting on the rotating governor

gear assembly causes the flyweights to move

outward as speed increases. Governor spring

tension moves them inward as speed decreases.

• As the flyweights move outward, they cause the

regulating pin to move outward.

• The regulating pin contacts the tab on the cross

shaft causing the shaft to rotate. One end of the

cross shaft protrudes through the crankcase. The

rotating action of the cross shaft is transmitted to

the throttle lever of the carburetor through the

external linkage. See Figure 5-66.

• When the engine is at rest, and the throttle is in

the “fast” position, the tension of the governor

spring holds the throttle plate open. When the

engine is operating, the governor gear assembly

is rotating. The force applied by the regulating

pin against the cross shaft tends to close the

throttle plate. The governor spring tension and

the force applied by the regulating pin balance

each other during operation, to maintain engine

speed.

• When load is applied and the engine speed and

governor gear speed decreases, the governor

spring tension moves the governor lever to open

the throttle plate wider. This allows more fuel

into the engine, increasing engine speed. As

speed reaches the governed setting, the governor

spring tension and the force applied by the

regulating pin will again offset each other to hold

a steady engine speed.

Hex

Nut

Cross Shaft

Governor Spring

Governor

Arm