11.8

Section 11

Reassembly

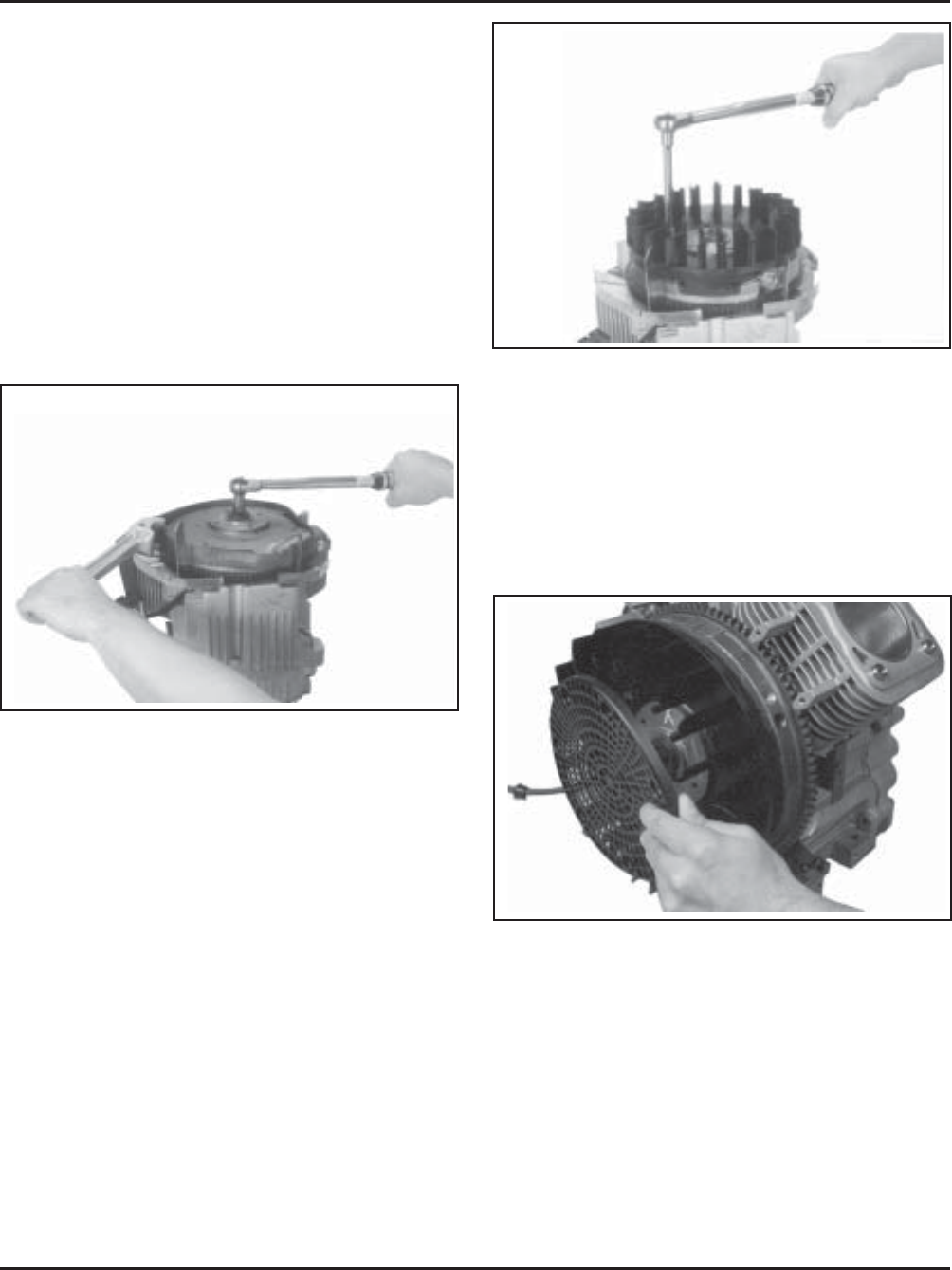

Figure 11-26. Installing Fan.

3. If the engine has a plastic grass screen, snap the

screen onto the fan. See Figure 11-27. Due to the

possibility of damaging the posts during removal,

install the retainers on different posts from which

they were removed. Start the retainers by hand,

then push them down with a 13 mm (1/2”) socket

until they lock. If the engine has a metal screen, it

will be installed later.

NOTE: Make sure the flywheel key is installed

properly in the keyway. The flywheel

can become cracked or damaged if the

key is not properly installed.

2. Install the flywheel onto the crankshaft being

careful not to shift the woodruff key. See Figure

11-24.

3. Install the hex flange screw and washer.

4. Use a flywheel strap wrench or holding tool to

hold the flywheel. Torque the hex flange screw

securing the flywheel to the crankshaft to

66.4 N·m (49 ft. lb.). See Figure 11-25.

Figure 11-25. Installing and Torquing Flywheel

Fastener.

Install Fan and Grass Screen

1. Install the fan onto the flywheel using the four

hex flange screws (engines with plastic grass

screen).

NOTE: Position the locating tabs on the back of the

fan in the recesses of the flywheel. See Figure

11-26.

2. Torque the screws to 9.9 N·m (88 in. lb.).

Figure 11-27. Installing Plastic Grass Screen.

Install Supports for the Metal Grass

Screen

1. If a metal grass screen is used, with threaded

individual supports, install a spacer washer on

the external threads. Apply blue Loctite

®

No 242

(removable) to the threads. Install the four

supports as shown in Figure 11-28.