5.22

Section 5

Fuel System and Governor

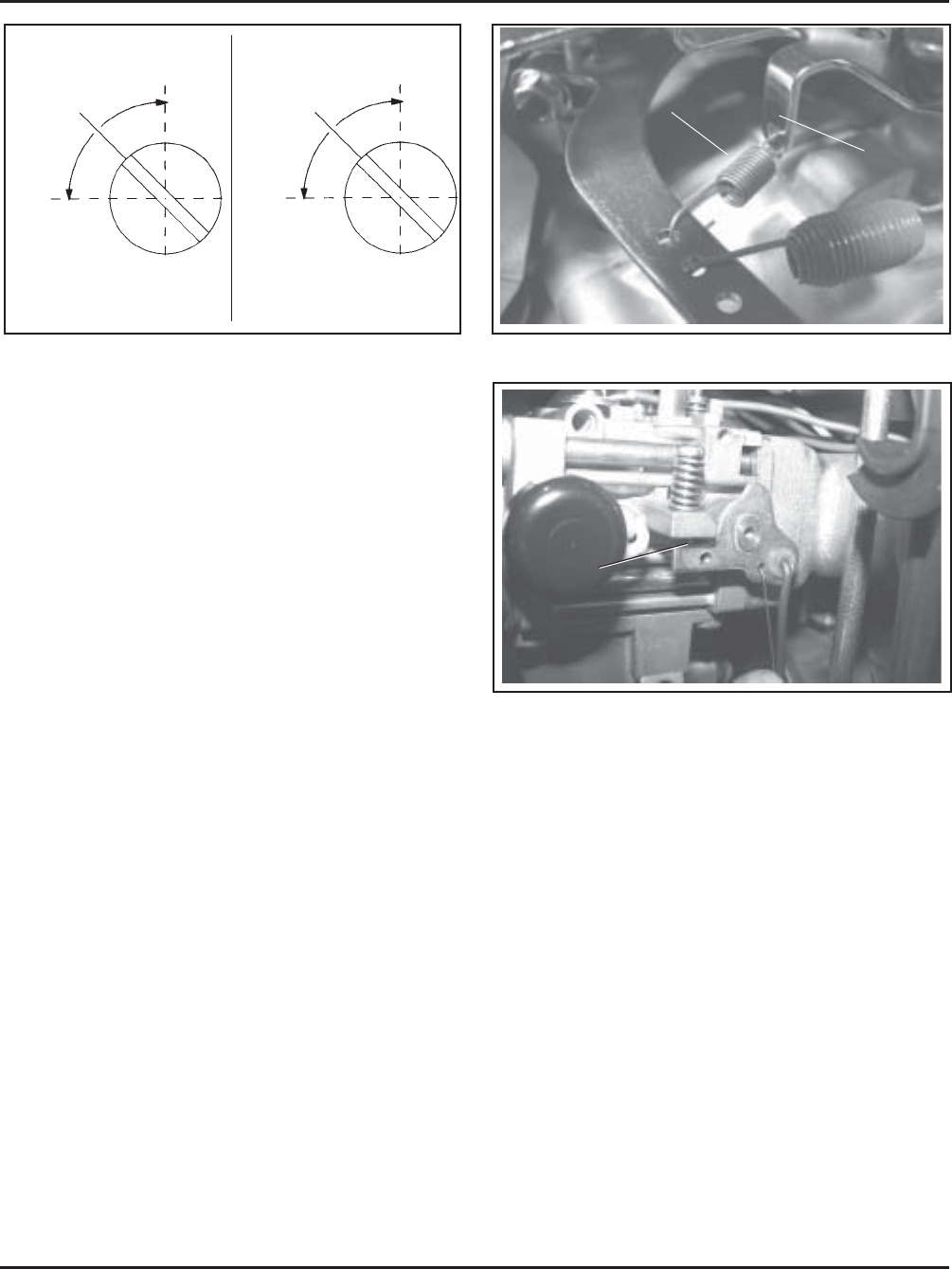

Figure 5-41. Governed Idle Spring Location.

Figure 5-40. Optimum Low Idle Fuel Settings.

Models with Governed Idle System

An optional governed idle control system is supplied

on some engines. The purpose of this system is to

maintain a desired idle speed regardless of ambient

conditions (temperature, parasitic load, etc.) that may

change. Engines with this feature contain a small

secondary spring connected between the governor

lever and the lower adjustment tab of the main

bracket. See Figure 5-41.

The system requires an additional procedure for

setting the idle speed. If speed adjustments are

required proceed as follows.

1. Make any necessary speed or control adjustments

following the appropriate instructions covered in

this section.

2. Move the throttle control to the idle position.

Hold the governor lever away from the

carburetor, or hold the throttle lever so it is tight

against the idle speed adjusting screw, to negate

the governor activation. See Figure 5-42. Check

the speed with a tachometer and adjust it to 1500

RPM.

3. Release the governor lever and allow the engine

to return to the governed idle speed. Check it

with a tachometer against the equipment

manufacturers recommended idle speed.

Governed Idle Speed (RPM) is typically 300 RPM

(approximate) higher than the low idle speed. If

adjustment is necessary, bend the adjusting tab on

the speed control assembly to set. See Figure 5-41.

Lean

Rich

Adjust to

Midpoint

Lean

Rich

Adjust to

Midpoint

Left Side Right Side

Governed

Idle Spring

Tab

Figure 5-42. Holding Throttle Lever Against Idle

Stop Screw (Two-Barrel Carburetor).

Carburetor Servicing

Float Replacement

If symptoms described in the carburetor

troubleshooting guide indicate float level problems,

remove the carburetor from the engine to check and/

or replace the float. Use a float kit to replace the float,

pin, float valve, clip and screw.

1. Perform the removal procedures for the Heavy

Duty Air Cleaner and Carburetor outlined in

Section 9 “Disassembly.”

2. Clean the exterior surfaces of dirt or foreign

material before disassembling the carburetor.

Remove the four mounting screws and carefully

separate the fuel bowl from the carburetor. Do

not damage the inner or bowl O-Ring. Transfer

any remaining fuel into an approved container.

Save all parts. Fuel can also be drained prior to

bowl removal by loosening/removal of the bowl

drain screw. See Figure 5-43.

Hold

Throttle

Lever

Against

Screw