5.14

Section 5

Fuel System and Governor

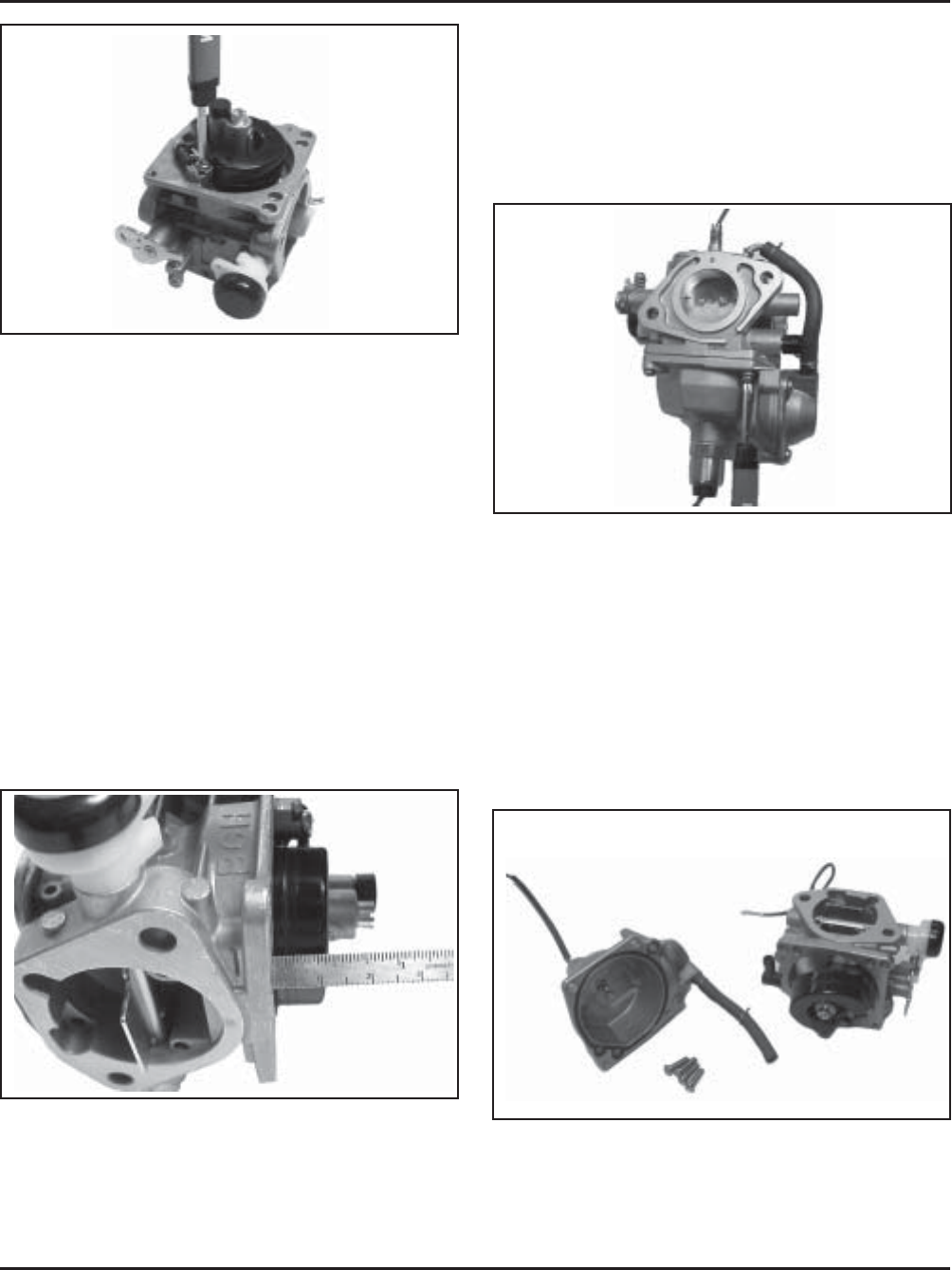

Figure 5-14. Installing Float Assembly.

6. Hold the carburetor body so the float assembly

hangs vertically and rests lightly against the fuel

inlet needle. The inlet needle should be fully

seated but the center pin of the needle (on

retainer clip end) should not be depressed. Check

the float height adjustment.

NOTE: The inlet needle center pin is spring loaded.

Make sure the float assembly rests against the

fuel inlet needle without depressing the

center pin.

7. The correct float height adjustment is 12.0 mm

(0.472 in.) measured from the float bottom to the

body of the carburetor. See Figure 5-15. Adjust

the float height by carefully bending the metal

tang of the float.

8. When the proper float height is obtained,

carefully reinstall the fuel bowl, with the

O-Ring(s) in place, onto the carburetor. Secure

with the four original screws. Torque the screws

to 2.5 ± 0.3 N·m (23 ± 2.6 in. lb.). Reattach the

accelerator pump hose (if so equipped), and

secure with the clip. See Figure 5-16.

Figure 5-15. Checking Float Height.

NOTE: Be sure to measure from the casting

surface, not the rubber gasket, if still

attached.

Figure 5-16. Installing Fuel Bowl.

Disassembly/Overhaul

1. Clean the exterior surfaces of dirt or foreign

material before disassembling the carburetor.

Unseat the clamp and disconnect the accelerator

pump hose (if so equipped), from the upper

fitting. Remove the four fuel bowl screws and

separate the fuel bowl from the carburetor.

Transfer any remaining fuel into an approved

container. Remove and discard the old O-Ring(s).

See Figure 5-17.

Figure 5-17. Fuel Bowl Removed from Carburetor.

NOTE: Further disassembly of fuel bowl is not

necessary unless the Accelerator Pump Kit

24 757 47-S, or Fuel Solenoid Kit 24 757 45-S

(obtained separately), are also being installed.