6.2

Section 6

Lubrication System

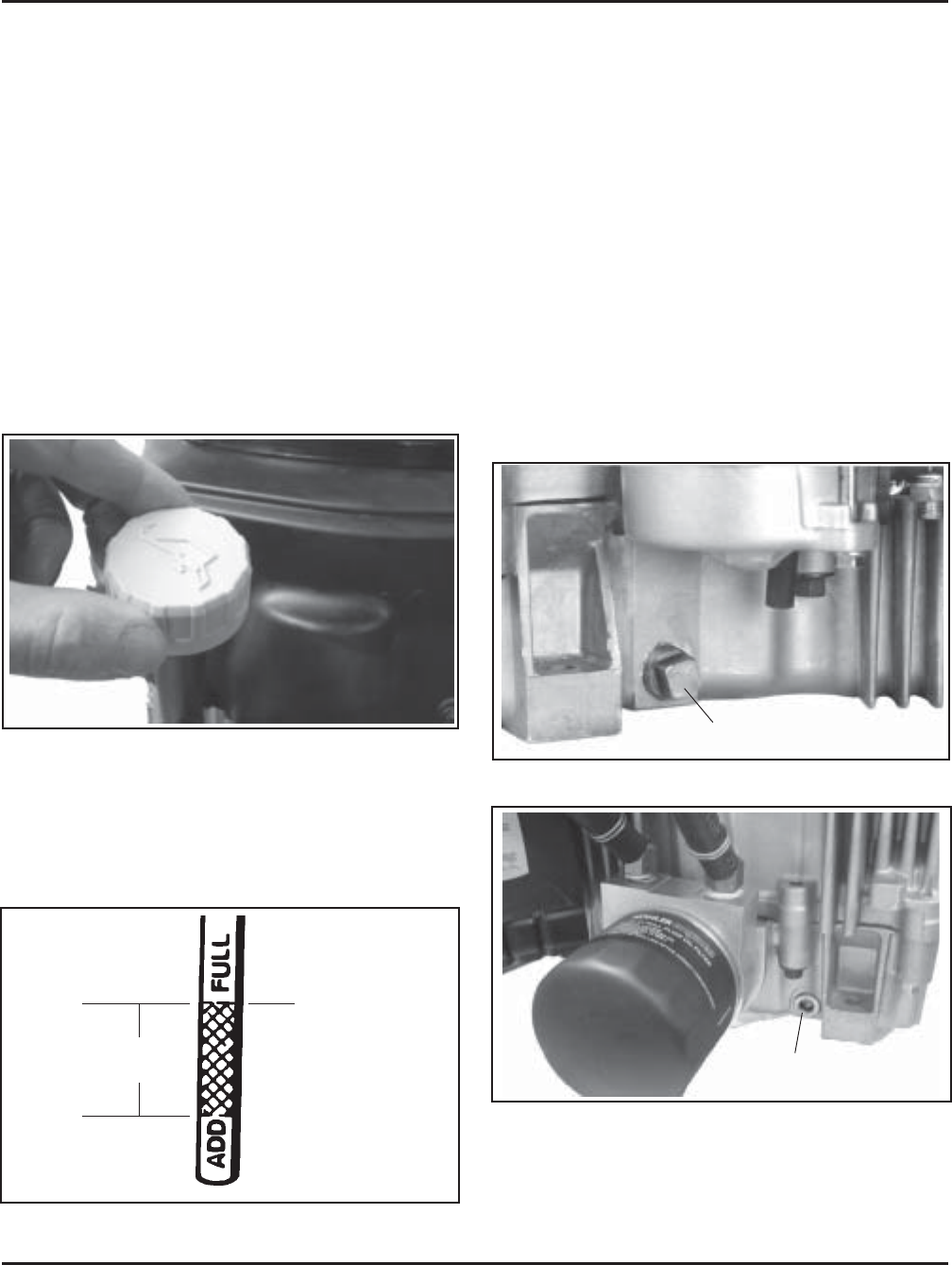

Figure 6-2. Oil Fill Cap/Dipstick.

4. Remove dipstick and check oil level. The level

should be between the FULL and ADD marks. If

low, add oil of the proper type up to the full

mark. Reinstall oil fill cap/dipstick and thread

tight.

Checking Oil Level

The importance of checking and maintaining the

proper oil level in the crankcase cannot be

overemphasized. Check oil BEFORE EACH USE as

follows:

1. Make sure the engine is stopped, level, and is cool

so the oil has had time to drain into the sump.

2. Clean the area around the oil fill cap/dipstick

before removing it. This will help to keep dirt,

grass clippings, etc., out of the engine.

3. Unthread and remove the oil fill cap/dipstick;

wipe oil off. Reinsert the dipstick into the tube

and rest the oil fill cap on the tube. Do not thread

the cap onto the tube. See Figure 6-2.

NOTE: To prevent extensive engine wear or damage,

always maintain the proper oil level in the

crankcase. Never operate the engine with the

oil level below the low mark or above the full

mark on the dipstick.

Changing Oil and Oil Filter

Changing Oil

Change the oil after every 100 hours of operation

(more frequently under severe conditions). Refill with

service class SG, SH, SJ or higher oil as specified in the

‘‘Viscosity Grades’’ table on page 6.1.

Change the oil while the engine is still warm. The oil

will flow more freely and carry away more

impurities. Make sure the engine is level when filling

or checking oil.

Figure 6-4. Oil Drain Plug (Starter Side).

Operating

Range

"Full" Mark

Figure 6-3. Oil Level Marks on Dipstick.

Figure 6-5. Oil Drain Plug (Oil Filter Side).

Oil Drain

Oil Drain

Oil Filter