11.6

Section 11

Reassembly

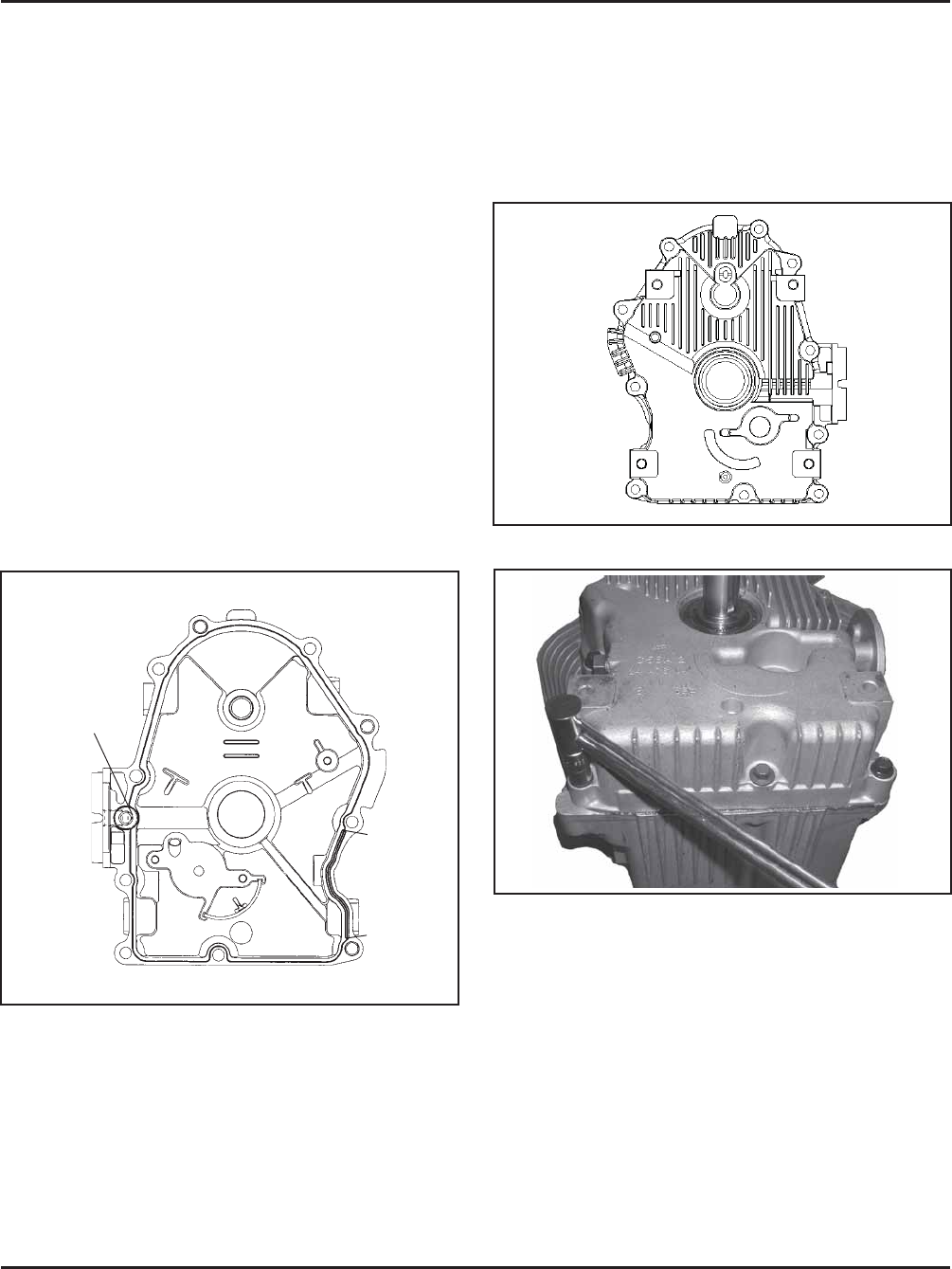

6. Install the ten hex flange screws securing the oil

pan to the crankcase. Torque the fasteners in the

sequence shown in Figure 11-18 to 24.4 N·m

(216 in. lb). On some engines one of the ten

mounting screws is plated. The plated screw is

typically installed in the #6 hole shown in Figure

11-18.

Figure 11-19. Torquing Oil Pan Fasteners.

Install Stator and Backing Plates

1. Apply pipe sealant with Teflon

®

(Loctite

®

No.

59241 or equivalent) to the stator mounting holes.

2. Position the stator aligning the mounting holes so

that the leads are at the bottom, towards the

crankcase.

3. Install and torque the two hex flange screws to

6.2 N·m (55 in. lb.). See Figure 11-20.

Install Oil Pan Assembly

RTV sealant is used as a gasket between the oil pan

and the crankcase on CV17-23 engines. CV25-750

engines use an oil pan gasket. Refer to Section 2 for a

listing of approved sealants. Always use fresh sealant.

Using outdated sealant can result in leakage.

1. Be sure the sealing surfaces have been cleaned

and prepared as described at the beginning of

Section 10 or in Service Bulletin 252.

2. Check to make sure that there are no nicks or

burrs on the sealing surfaces of the oil pan or

crankcase.

3. Apply a 1.5 mm (1/16 in.) bead of sealant to the

sealing surface of the oil pan on CV17-23 engines.

See Figure 11-17 for the sealant pattern. On

CV25-750 engines use a new gasket. Before

installing the gasket, check the dowel pin on the

oil filter side of the crankcase. If a “split” style

dowel pin is contained, replace it with a closed

seam style pin provided with the new gasket.

Figure 11-17. Oil Pan Sealant Pattern CV17-23.

4. Make sure the end of the governor cross shaft is

lying against the bottom of cylinder 1 inside the

crankcase. See Figure 11-13.

5. Install the oil pan to the crankcase. Carefully seat

the camshaft and the crankshaft into their mating

bearings. Rotate the crankshaft slightly to help

engage the oil pump and governor gear meshes.

Apply 1.5 mm (1/16 in.)

bead of sealant.

RTV must be

all around

O-Ring

groove

Point "B"

Fill groove between points "A" and "B" with RTV.

Point "A"

Figure 11-18. Oil Pan Fastener Torque Sequence.

1

10

8

6

4

2

9

7

5

3