10.13

Section 10

Inspection and Reconditioning

10

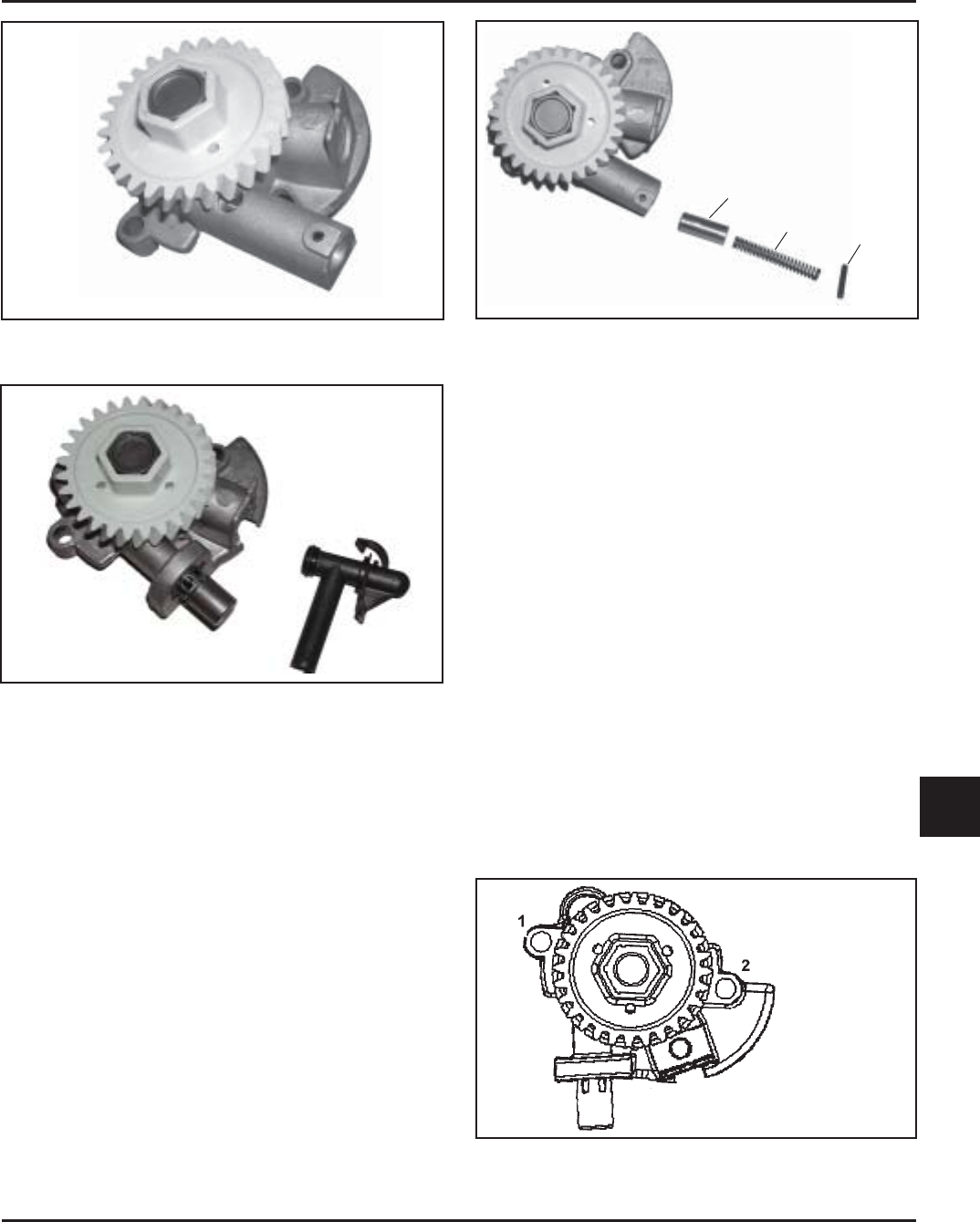

Figure 10-16. Oil Pump, Oil Pickup, and Relief

Valve (Original Style).

Figure 10-17. Oil Pump, Plastic Oil Pickup, and

One-Piece Relief Valve (Later Style).

Inspection

Inspect the oil pump housing, gear, and rotors for

nicks, burrs, wear, or any visible damage. If any parts

are worn or damaged, replace the oil pump.

Inspect the oil pressure relief valve piston. It should be

free of nicks or burrs.

Check the spring for wear or distortion. The free

length of the spring should be approximately 47.4 mm

(1.8 in.). Replace the spring if it is distorted or worn.

See Figure 10-18.

Figure 10-18. Oil Pressure Relief Valve Piston and

Spring.

Reassembly

1. Install the pressure relief valve piston and spring.

2. Install the oil pickup to the oil pump body.

Lubricate the O-Ring with oil and make sure it

remains in the groove as the pickup is being

installed.

3. Install the rotor.

4. Install the oil pump body to the oil pan and

secure with the two hex flange screws. Torque the

hex flange screws as follows:

a. Install fastener into location No. 1 and lightly

tighten to position pump.

b. Install fastener into location No. 2 and fully

torque to the recommended value.

c. Torque fastener in location No. 1 to the

recommended value.

Piston

Spring

Roll Pin

First Time Installation: 10.7 N·m (95 in. lb.)

All Reinstallations: 6.7 N·m (60 in. lb.)

Oil Pump Torque Sequence