5.26

Section 5

Fuel System and Governor

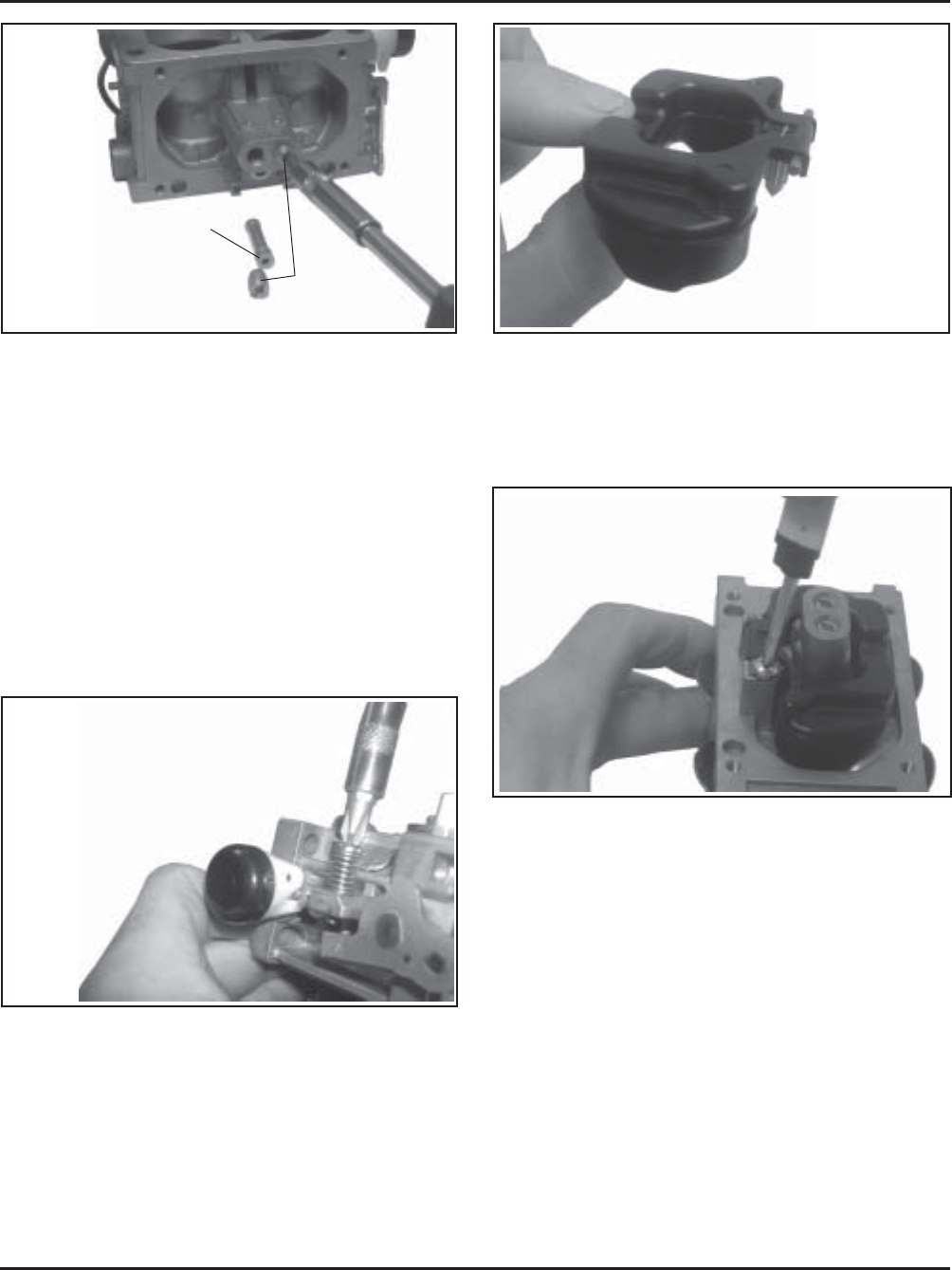

Figure 5-57. Installing Float Assembly.

14. Hold the carburetor body so the float assembly

hangs vertically and rests lightly against the fuel

inlet needle. The inlet needle should be fully

seated but the center pin of the needle (on

retainer clip end) should not be depressed. Check

the float height adjustment.

NOTE: The inlet needle center pin is spring

loaded. Make sure the float rests against

the fuel inlet needle without depressing

the center pin.

15. The correct float height setting is 17 mm

(0.669 in.) ± 1.5 mm (0.059 in.), measured from

the float bottom to the body of the carburetor. See

Figure 5-58. Replace the float if the height is

different than the specified setting. Do not

attempt to adjust by bending float tab.

Figure 5-56. Float and Inlet Needle Details.

13. Install the float and inlet needle down into the

seat and carburetor body. Install the new pivot

pinthrough the float hinge and secure with the

new retaining screw. See Figure 5-57.

Figure 5-54. Installing Main Nozzles and Main Jets.

9. Make sure the O-Ring near the bottom of each

slow jet is new, or in good condition. Align and

insert the two slow jets into the top of carburetor.

See Figure 5-53.

10. Install the large flat retaining washer and secure

with the mounting screw, attaching the ground

lead if originally secured by the screw.

11. Install the new idle speed (RPM) adjustment

screw and spring onto the carburetor. Thread in

until 3 or 4 threads are exposed, as an initial

adjustment. See Figure 5-55.

Nozzle End with Two

Shoulders (Out/Down)

Main Jets

Figure 5-55. Installing Idle Speed Adjusting Screw

and Spring.

12. Attach the inlet needle to the plastic tang of the

float with the wire clip. The formed 90° lip

should point up, with the needle valve hanging

down. See Figure 5-56.