11.13

Section 11

Reassembly

11

Figure 11-43. Using Spanner Wrench to Lift Rocker

Arm Over Push Rod.

5. Repeat the above steps for the remaining

cylinder. Do not interchange parts from the

cylinder heads.

6. Rotate the crankshaft to check for free operation

of the valve train. Check the clearance between

the valve spring coils at full lift. Minimum

allowable clearance is 0.25 mm (0.010 in.).

Check Assembly

Important: Rotate the crankshaft a minimum of two

revolutions to check longblock assembly and overall

proper operation.

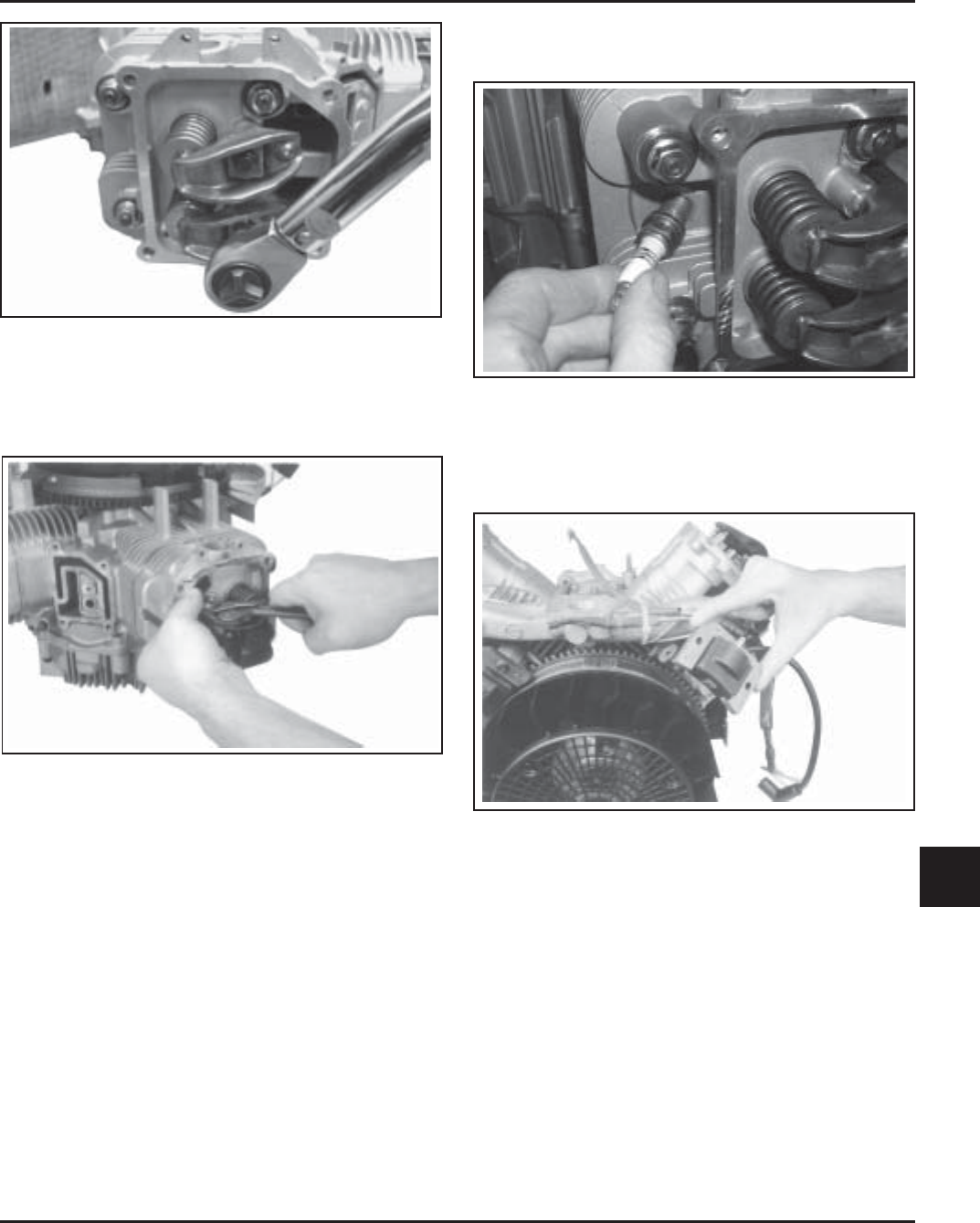

Install Spark Plugs

1. Use new Champion

®

(or equivalent) spark plugs.

2. Set the gap at 0.76 mm (0.030 in.).

Figure 11-44. Installing Spark Plugs.

Install Ignition Modules

1. Rotate the flywheel to position the magnet away

from the ignition module bosses.

Figure 11-45. Installing Ignition Modules.

2. On engines equipped with SMART-SPARK

™,

both

modules are installed the same way – with the

two tabs out. See Figure 11-46 and 11-52.

On engines not equipped with SMART-SPARK

™

the modules are installed with the spark plug

lead wire from module always away from the

cylinder. On #1 cylinder, the single kill tab should

be towards you. See Figure 11-45. On #2 cylinder,

the single kill tab should be away from you (in).

3. Install each ignition module to the crankcase

bosses with the two screws (hex flange or allen

head, based on model). Slide the modules up as

far away from the flywheel as possible and snug

the screws to hold them in that position.

Figure 11-42. Torquing Rocker Arm Screws.

4. Use a spanner wrench or rocker arm lifting tool

(see Section 2), to lift the rocker arms and

position the push rods underneath. See Figure

11-43.

3. Install new plugs and torque to 24.4-29.8 N·m

(18-22 ft. lb.). See Figure 11-44.