10.14

Section 10

Inspection and Reconditioning

5. After torquing, rotate the gear and check for

freedom of movement. Make sure there is no

binding. If binding occurs, loosen the screws,

reposition the pump, retorque the hex flange

screws and recheck the movement.

Crankcase Breather System

The breather system is designed to control the amount

of oil in the head area and still maintain the necessary

vacuum in the crankcase.

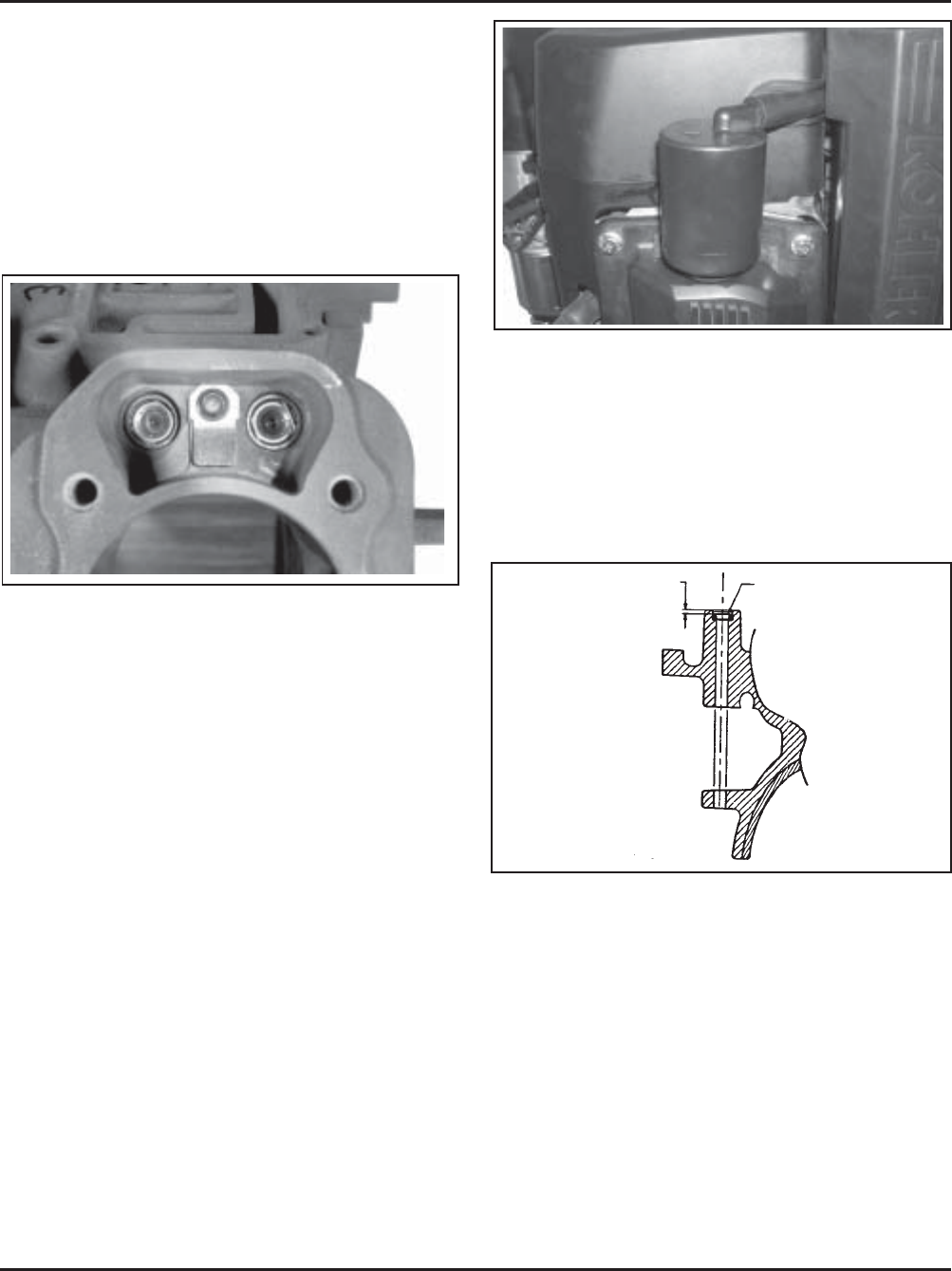

Figure 10-20. Oil Separator.

Governor Cross Shaft Oil Seal

If the governor cross shaft seal is damaged and/or

leaks, replace it using the following procedure.

Remove the oil seal from the crankcase and replace it

with a new one. Install the new seal to the depth

shown in Figure 10-21 using a seal installer.

Figure 10-19. Crankcase with Breather Reed.

A spring steel reed and stop is mounted on each bank

of the crankcase, between the lifter bores. See Figure

10-19. When the pistons move downward, air is

pushed past the reeds into the cylinder head cavities.

On the #2 cylinder, the upper end of the head is

completely sealed by the rocker cover, so a low,

positive pressure is created in the head cavity. The #1

rocker cover has a hole in it for venting. The bottom

nipple of an oil separator canister is fitted into the

hole with a grommet. From the top nipple of the

canister, a breather hose goes back to the air cleaner

base. The air moving into the #1 head cavity is filtered

through the oil separator and then is drawn into the

air intake. See Figure 10-20.

The upward travel of the pistons closes the reeds and

creates a low vacuum in the lower crankcase. The

combination of low pressure above and low vacuum

below forces any accumulated oil out of the #2 head

area into the crankcase. On the #1 bank you have

atmospheric pressure above and vacuum below, again

drawing any oil toward the crankcase.

2.0 mm (0.0787 in.)

Governor Cross

Shaft Seal

Figure 10-21. Installing Cross Shaft Oil Seal.