10.2

Section 10

Inspection and Reconditioning

The connecting rod journal can be ground one size

under. When grinding the crankshaft, grinding stone

deposits can get caught in the oil passages, which

could cause severe engine damage. Removing the

crankpin plug when the crankshaft is ground provides

easy access for removing any grinding deposits that

may collect in the oil passages.

Use the following procedure to remove and replace

the plug.

Procedure to Remove Crankshaft Plug:

1. Drill a 3/16" hole through the plug in the

crankshaft.

2. Thread a 3/4" or 1" long self-tapping screw with a

flat washer into the drilled hole. The flat washer

must be large enough to seat against the shoulder

of the plug bore. See Figure 10-2.

3. Tighten the self-tapping screw until it draws the

plug out of the crankshaft.

Procedure to Install New Plug:

1. Use a single cylinder camshaft pin Part No.

47 380 09-S as a driver and tap the plug into the

plug bore until it seats at the bottom of the bore.

Make sure the plug is tapped in evenly to prevent

leakage.

Inspect the crankshaft bearing surfaces for scoring,

grooving, etc. Measure the running clearance between

the crankshaft journals and their respective bearing

bores. Use an inside micrometer or telescoping gauge

to measure the inside diameter of both bearing bores

in the vertical and horizontal planes. Use an outside

micrometer to measure the outside diameter of the

crankshaft main bearing journals. Subtract the journal

diameters from their respective bore diameters to get

the running clearances. Check the results against the

specifications in Section 1. If the running clearances

are within specification, and there is no evidence of

scoring, grooving, etc., no further reconditioning is

necessary. If the bearing surfaces are worn or

damaged, the crankcase and/or oil pan will need to be

replaced.

Inspect the crankshaft keyways. If worn or chipped,

replacement of the crankshaft will be necessary.

Inspect the crankpin for score marks or metallic

pickup. Slight score marks can be cleaned with crocus

cloth soaked in oil. If wear limits, as stated in

“Specifications and Tolerances” are exceeded, it will

be necessary to either replace the crankshaft or regrind

the crankpin to 0.25 mm (0.010 in.) undersize. If

reground, a 0.25 mm (0.010 in.) undersize connecting

rod (big end) must then be used to achieve proper

running clearance. Measure the crankpin for size,

taper, and out-of-round.

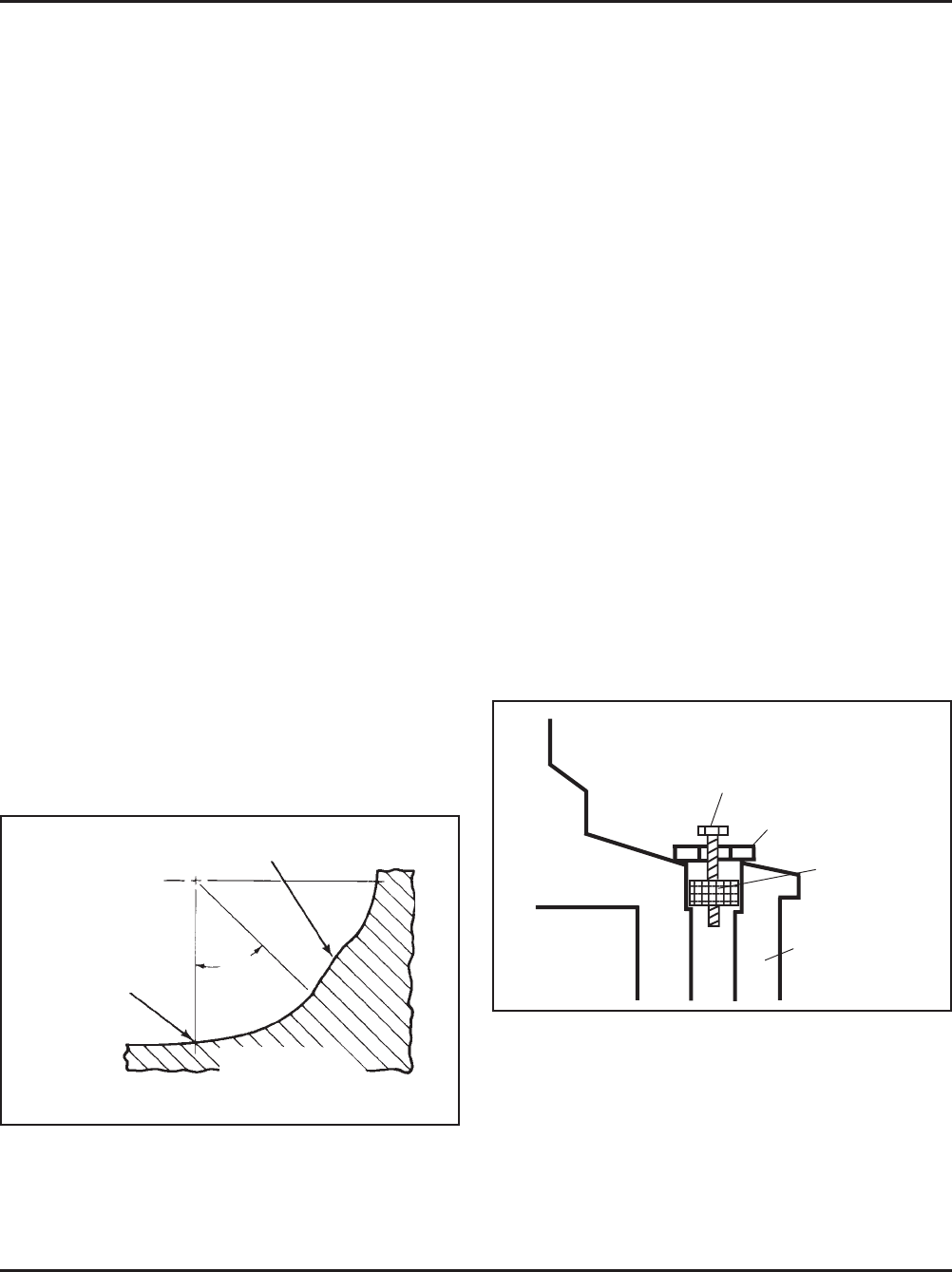

NOTE: If the crankpin is reground, visually check to

insure that the fillet blends smoothly with the

crankpin surface. See Figure 10-1.

Figure 10-1. Crankpin Fillets.

Figure 10-2. Removing Crankpin Plug.

45°

High Point from

Fillet Intersections

This Fillet Area

Must Be Completely

Smooth

Minimum

The Fillet Must

Blend Smoothly

with the Bearing

Journal Surface

Flat Washer

Self-Tapping Screw

Plug

Crankshaft