62--113625--1

SECTION 5

FUEL SYSTEM

5.1 CHECKING AND ADJUSTING

5.1.1 Injection Timing

1. Remove the fuel speed solenoid.

2. Remove the injection pipes and nozzle.

3. Move the speed control lever to the maximum speed

position.

NOTE

T urn the flywheel with a screwdriver .

4. Turn the flywheel counterclockwise (facing the fly-

wheel) until the fuel fills up the hole of the delivery

valve holder for #1 cylinder.

5. Turn the flywheel further and stop turning when the

fuel begins to flow over.

6. Open the view port on the flywheel bell housing and

read the number on the flywheel. The number indi-

cated is the timing value for the engine. (The flywheel

has a mark ’1TC’ and marks every 5° of engine timing

to 25° total).

Injection Timing

Factory

Specification

0.0568 to 0. 0829 rad.

3.25

° to 4. 75°

B.T.D.C.

NOTE

Injection timing adjustment is accomplished by

adding or removing shims under the injection

pump.

The timing advances byremovingone shimand

retards timing by adding the same shim.

The addition or removal of 0.05 mm (0.0020in.)

of shim, changes the injection timing by approx-

imately 0.009 rad. (0.5°).

Sealant should be applied to both sides of soft

metal gasket shims except for the .0175mm

shim. A .0175mm shim should have sealant ap-

plied to one side only.

When replacing the injection pump be sure to

use the same number and size of new gasket

shims.

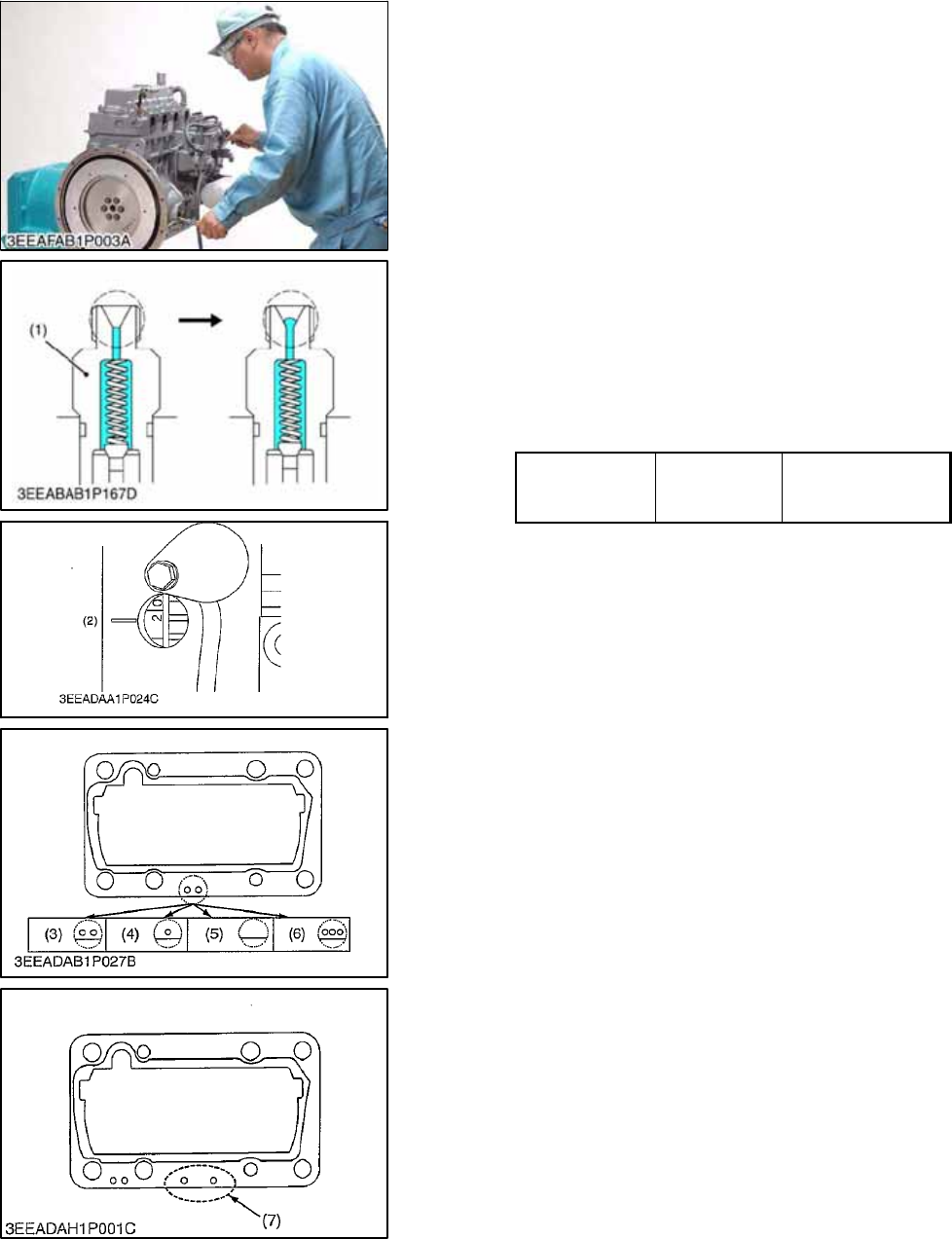

5.1.2 Shim Identification

Shims are available in thicknesses of 0.20 mm,

0.25 mm, 0.30 mm, and 0.35mm. Combine

shims for adjustments.

1. Delivery Valve Holder

2. Timing Mark

3. 2--Holes: 0.20 mm s him

4. 1--Hole: 0.25 mm shim

5. 0--Holes: 0.30 mm s him

6. 3--Holes: 0.35 mm s him

7. 2--Holes: 0.175 mm shim