2--15

62--11362

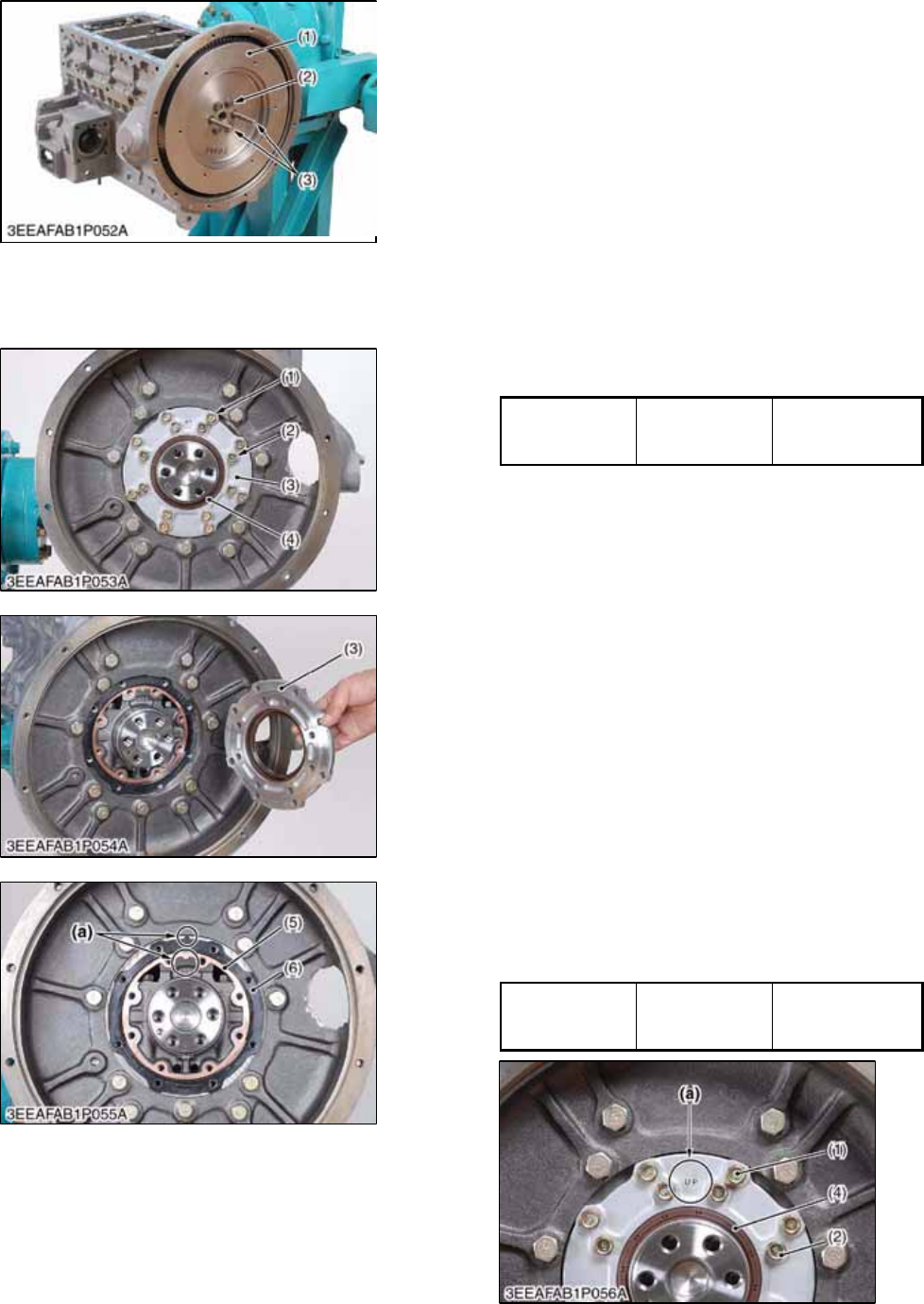

2.2.7 Crankshaft

1. Flywheel

2. Fl

y

wheel Bolt

3. Flywheel G uide Bolts

1. Bearing Case Cover

Mounting Bolt

2. Bearing Case Cover

Mounting bolt

3. Bearing Case Cover

4. Oil Seal

5. Bearing Case Gasket

6. Bearing Case Cover

Gasket

(a). Top

2.2.7.a Flywheel

1. Prevent the flywheel (1) from rotating.

2. Remove two flywheel bolts (2).

NOTE

The use of air tools to remove the flywheel bolts

may damage the threads in the crankshaft.

3. Install two flywheel guide bolts (3).

4. Remove all of the flywheel bolts (2).

5. Remove the flywheel (1) slowly along the flywheel

guide bolts (3).

When Reassembling

Install two flywheel guide bolts (3).

Check to see that the mating surfaces of the crankshaft

and flywheel are clean.

Apply engine oil to the flywheel bolts and install.

Tightening

Torque

Flywheel Bolts

98.0 to 107. 8 N

.

m

10.0 to 11.0 kgf

.

m

72.3 to 79. 5 ft--lbs

2.2.7.b Bearing Case Cover

1. Remove thebearing case covermountingbolts. First,

remove the inside bolts ( 2) and then the outside bolts

(1).

2. Screw two of the removed bolts into the bolt hole of

the bearing case cover (3) to remove it.

NOTE

The length o f the inside (2) and the outside (1)

bolts is different. When reassembling reinstall

the appropriate bolt in the correct location.

When Reassembling

Fit the bearing case gasket (5) and the bearing case

cover gasket (6) to the bearing case cover (3). Orient

them correctly.

Install the bearing case cover (3), again orienting it

correctly, using the “UP” mark (a).

Apply oil to the oil seal (4), and take care not to roll the

seal when installed.

T ighten the bearing case cover bolts diagonally and

evenly.

Tightening

Torque

Bearing C ase

Cover Mounting

bolt

24 to 27 N

.

m

2.4to2.8kgf

.

m

18 to 20 ft--lbs