33

6 F 8 A 0 9 3 4

6. Operation

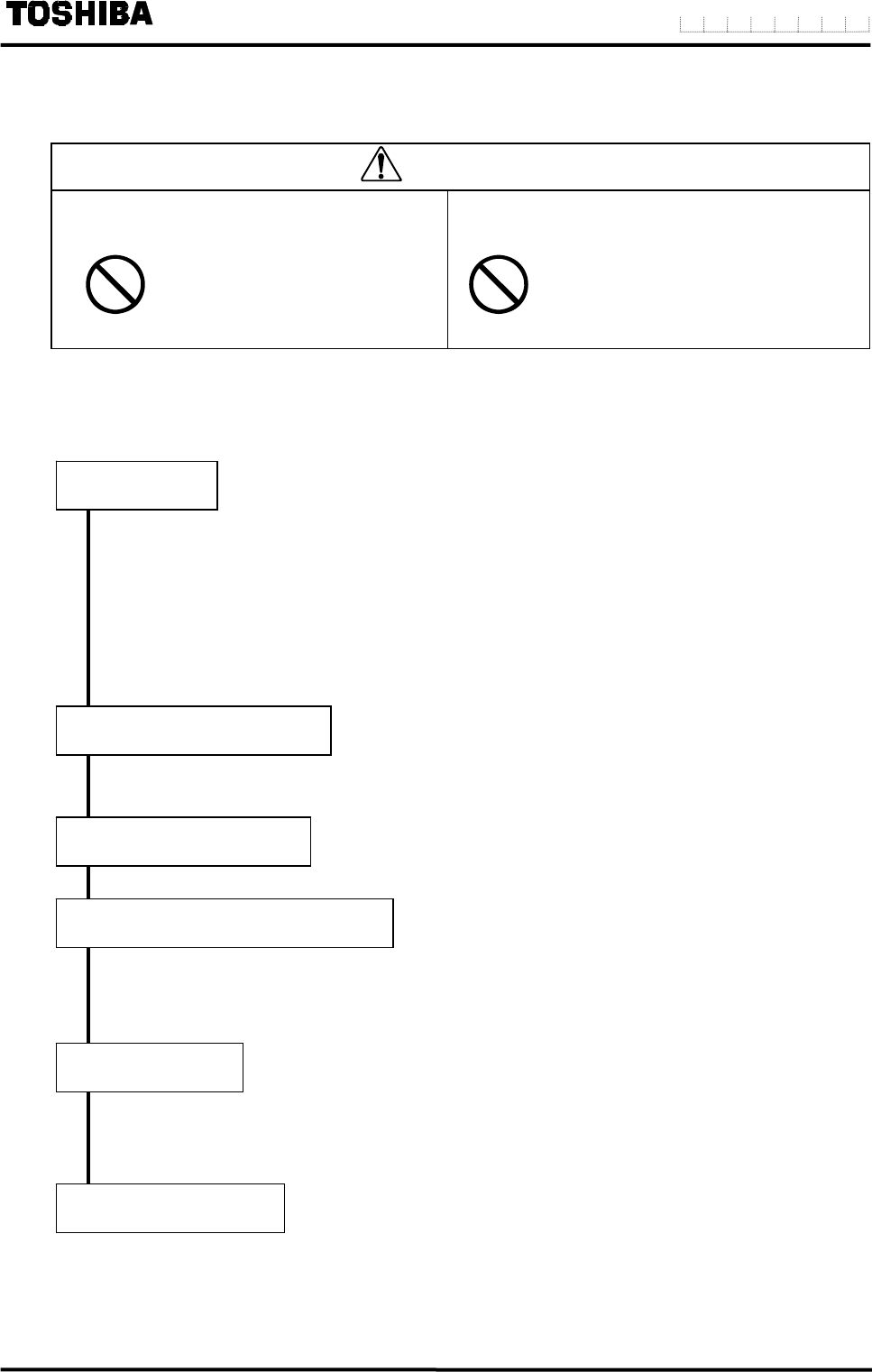

CAUTION

Do not touch the terminal board when power

is supplied.

Do not touch the main body when high

temperature fluid is being measured.

DON’T

Touching the terminal board

when power is supplied can

cause electric shock.

DON’T

The fluid raises the main body

temperature and can cause burns.

6.1 Preparatory check

Follow the procedure described below to prepare before starting the flow measurement

Check the items listed below

Check the wiring between the converter and related instruments.

Make sure all the bolts of connection flanges on which the flowmeter is mounted

securely tightened.

Make sure the direction of flow arrow is in accordance with actual flow.

Make sure the flowmeter is grounded with 100 ohm or less ground resistance.

Make sure the converter housing covers are securely tightened.

Let the fluid go through the detector pipe. (Note 1)

When the detector is filled with the fluid, stop the fluid and keep it still in the detector pipe.

Make sure the power supply is as specified.

Check the configuration parameter settings. Refer to Chapter 7, “LCD Display and

Controls,” Chapter 8, “Configuration Parameter Setting,” and Chapter 11,

“Communications Function.”

Wait for 30 minutes to warm up the flowmeter. Then making sure the fluid holds still in the

detector pipe before starting the zero adjustment.

Refer to 6.2, “Zero Adjustment.”

After checking the items and conducting the zero adjustment as listed above, let the fluid go

through the detector pipe. Output (4–20 mA dc) directly proportional to the flow rate can be

obtained.

System Check

Placing System On-Stream

Supplying Electric Power

Checking Converter Parameters

Zero Adjustment

On-line measurement