Close out VNC to the on-board computer. You are now ready to start the Monster Truck

program from the main command console.

CHAPTER 6 – Time Replacement Items

6-1 REPLACEMENT OF INVERTER PARTS

The inverter consists of many electronic parts such as semiconductor devices. The following

parts may deteriorate with age due to their structure or physical characteristics, leading to

reduced performance or failure of the inverter. For preventative maintenance, the parts must

be changed periodically.

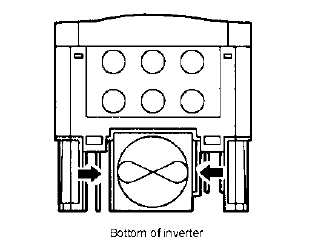

6-1A COOLING FAN

The cooling fan cools heat generating parts such as the main circuit semiconductor devices.

The life of the cooling fan bearing is usually 10,000 to 35,000 hours. Hence, the cooling fan

must be changed every 2 to 3 years if the inverter is run continuously. When unusual noise

and/or vibration is noticed during inspection, the cooling fan must be changed immediately.

Figure 1 Fan replacement

Removal

3) Push the catches on both sides and pull the fan casing down.

4) Disconnect the fan power connector.

Reinstallation

3) Reconnect the fan power connector.

Push the fan casing up until it locks into place.

6-1B SMOOTHING CAPACITORS

A large-capacity aluminum electrolytic capacitor is used for smoothing the DC in the main

circuit, and an aluminum electrolytic capacitor is also used for stabilizing the control power

in the control circuit. Their characteristics are adversely affected by ripple current, etc.

When the inverter is operated in an ordinary, air-conditioned environment, change the

capacitors about every 5 years. When 5 years have elapsed, the capacitors will deteriorate

more rapidly.

Check the capacitors at least every year (less than six months if their life will be expired

soon).

Check the following:

1.) Case (side faces and bottom face for expansion)

2.) Sealing plate (for remarkable warping and extreme cracks)

3.) Explosion-proof valve (for excessive valve expansion and operation)