VALVES AND VALVE SPRINGS

5-19

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

4. Check:

•Valve face

Pitting/wear → Grind the valve face.

• Valve stem end

Mushroom shape or diameter larger than

the body of the valve stem → Replace the

valve.

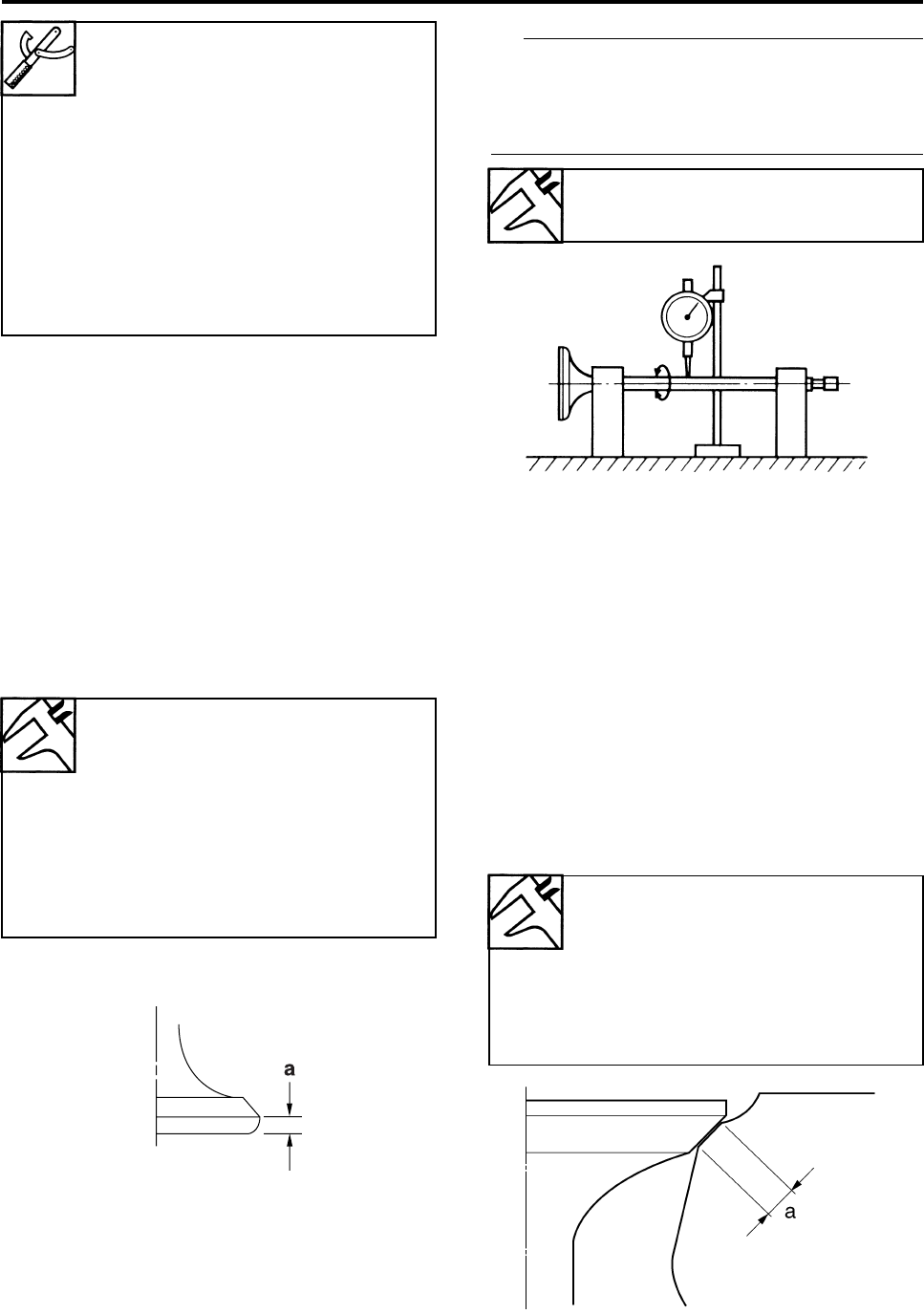

5. Measure:

• Valve margin thickness D “a”

Out of specification → Replace the valve.

6. Measure:

• Valve stem runout

Out of specification → Replace the valve.

TIP

• When installing a new valve, always replace

the valve guide.

• If the valve is removed or replaced, always

replace the oil seal.

EAS24300

CHECKING THE VALVE SEATS

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

2. Check:

• Valve seat

Pitting/wear → Replace the cylinder

head.

3. Measure:

• Valve seat width C “a”

Out of specification → Replace the cylin-

der head.

Valve guide remover (ø6)

90890-04064

Valve guide remover (6.0 mm)

YM-04064-A

Valve guide installer (ø6)

90890-04065

Valve guide installer (6.0 mm)

YM-04065-A

Valve guide reamer (ø6)

90890-04066

Valve guide reamer (6.0 mm)

YM-04066

Valve margin thickness

Valve margin thickness D

(intake)

0.80–1.20 mm (0.0315–0.0472

in)

Valve margin thickness D

(exhaust)

0.80–1.20 mm (0.0315–0.0472

in)

Valve stem runout

0.01 mm (0.0004 in)

Valve seat width

Valve seat width C (intake)

0.90–1.10 mm (0.0354–0.0433

in)

Valve seat width C (exhaust)

0.90–1.10 mm (0.0354–0.0433

in)