62 CLCH-IM-16A

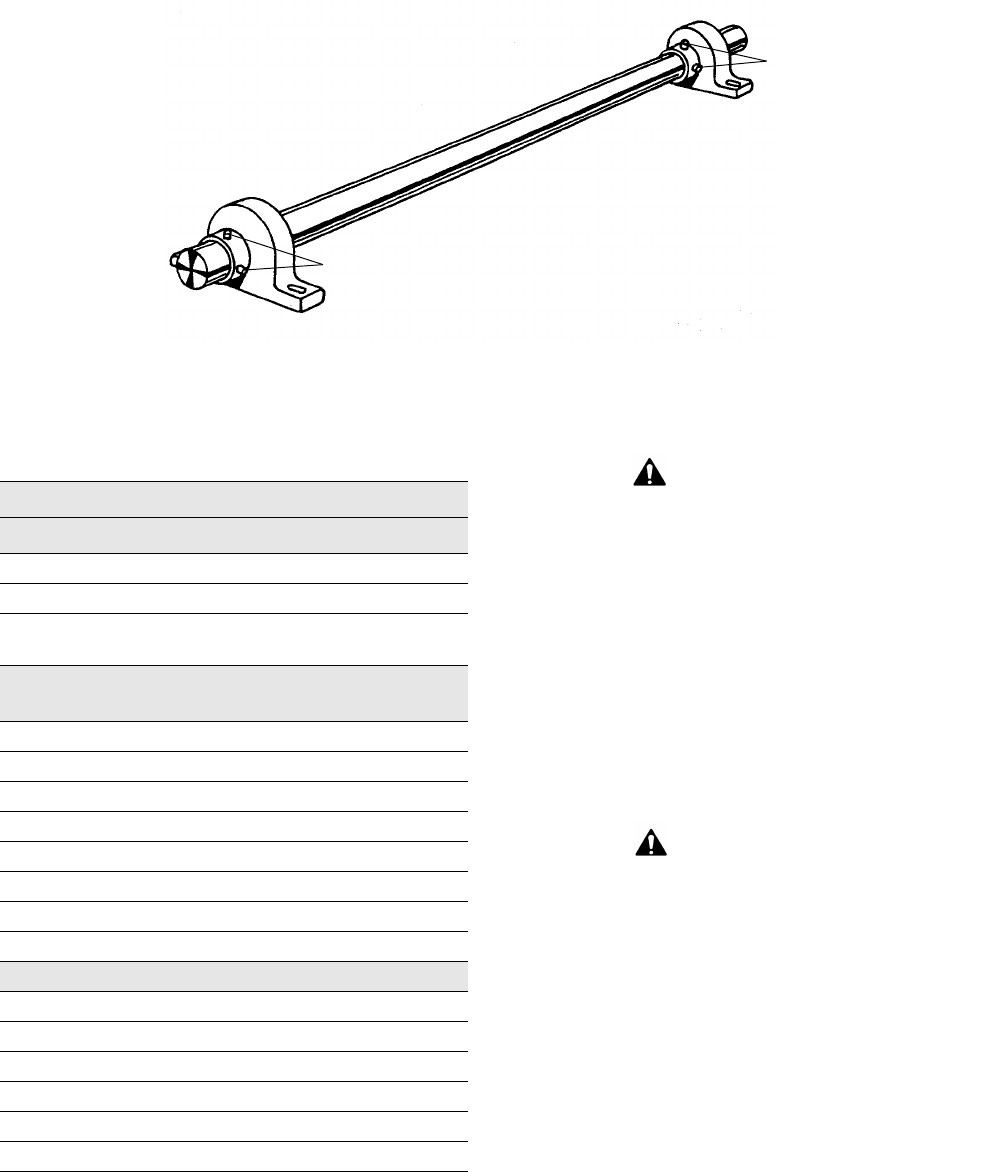

Figure 50

Bearing Setscrew Alignment

Fan Bearing Lubrication

Note: Greases used should conform to NLGI No. 2 penetration.

Fan bearings should be lubricated with a lithium base

grease which conforms to NLGI Number 2 for

consistency. See

Table 49

and

Table 50

for

recommended lubricants and bearing grease

capacities.

CAUTION

Improper lubrication can result in

premature bearing failure.

Do not mix greases with different

bases within the bearing. This can

cause an audible squealing noise

that may be transmitted through

the system ductwork. Premature

bearing failure may result.

To lubricate the fan bearings, complete the following:

WARNING

Disconnect electrical power

source before servicing the unit. If

unit must be on for maintenance

procedures, exercise extreme cau-

tion. Failure to do so may result in

personal injury or death from elec-

trical shock or entanglement in

moving parts.

Disconnect electrical power prior

to access into a fan or ductwork.

Even when locked out electrically,

fans may cause injury or damage if

the impeller is subject to “wind-

milling.” The impeller should be

Set Screws (2)

Set Screws (2)

Table 49

Recommendations for Grease-Lubricated Fan Bearings

Greasing Intervals

Operating Conditions -20

°

F to +140

°

F 140

°

F to 200

°

F

Clean, Dry

3-6 months 1-3 months

Dirty, Dry

1-3 months 1-4 weeks

Dirty, Wet, High

Humid.

1-4 weeks 1-14 days

Recommended

Greases

Recommended Operating Range

Texaco-Multi Fak #2

-20

°

F to +250

°

F

Shell Alvania #2

-20

°

F to +250

°

F

Mobil Mobilux #2

-20

°

F to +250

°

F

Exxon Unirex #2

-20

°

F to +250

°

F

Texaco Prem. RB

-20

°

F to +250

°

F

Mobil 532

-20

°

F to +250

°

F

Exxon Beacon

-65

°

F to +250

°

Keystone 84H

-40

°

F to +225

°

F

Shaft Size (In)

Max. Grease Cap. of Bearing (Oz.)

1/2 to 3/4

1/8

7/8 to 1-3/16

3/8

1-1/4 to 1-1/2

5/8

1-11/16 to 1-15/16

7/8

2 to 2-7/16

1-1/4

2-1/2 to 2-15/16

2