60 CLCH-IM-16A

*NOTE: Soft metric conversions not acceptable for screw and hex

sizes

q Check damper linkages, set screws and blade

adjustment. Clean, but do not lubricate, the nylon

damper rod bushings.

q Clean damper operators.

q Inspect the control and power box wiring for

secure connections and insulation.

q Rotate the fan wheel and check for obstructions in

the fan housing. The wheel should not rub on the

fan housing. Adjust the center if necessary and

tighten wheel set screws to the proper torque.

q Check condition of gasketing and insulation

around unit, door and dampers.

q Examine flex connections for cracks or leaks.

Repair or replace damaged material.

Drain Pans

Inspecting and Cleaning Drain Pans

For units with sloped drain pans

, if evidence of

standing water or condensate overflow exists,

identify and remedy the cause immediately. (Refer to

the troubleshooting section for possible causes and

solutions.) If microbial growth (mold) in the drain pan

is observed, clean the pan immediately using the

following procedure:

7 Disconnect all electrical power to the unit.

8 Don the appropriate personal protective

equipment (PPE).

9 Remove all standing water.

10 Use a scraper or other tools to remove any solid

matter. Remove solid matter with a vacuum

device that uses high efficiency particulate

arrestance (HEPA) filters with a minimum

efficiency of 99.97% at 0.3 micron particle size.

11 Thoroughly clean the contaminated area with a

mild bleach and water solution or an EPA-

approved sanitizer specifically designed for HVAC

use. Carefully follow the sanitizer manufacturer’s

instructions regarding the use of the product.

12 Immediately rinse the drain pan thoroughly with

fresh water to prevent potential corrosion from the

cleaning solution of the drain pan and drain line

components.

13 Allow the unit to dry thoroughly before putting the

system back into service.

14 Determine and correct the cause of the microbial

contamination.

15 Be careful that the contaminated material does

not contact other areas of the unit or building.

Properly dispose of all contaminated materials

and cleaning solution.

IMPORTANT: STANDING WATER IN DRAIN PANS CAN

PROMOTE MICROBIAL GROWTH (MOLD) THAT MAY

CAUSE UNPLEASANT ODORS AND SERIOUS

HEALTH-RELATED INDOOR AIR QUALITY

PROBLEMS. IF MOLD IS FOUND, IT MUST BE

REMOVED IMMEDIATELY AND THAT PORTION OF

THE UNIT PROPERLY CLEANED AND SANITIZED.

Air Filters

Catalog data tables provide filter size, type and

quantity.

Throwaway Filters

To replace throwaway filters, install new filters with

the directional arrows pointing in direction of airflow.

NOTE: FILTERS MUST HAVE AN AIRTIGHT SEAL TO

PREVENT AIR BYPASS. IF USING OTHER THAN

TRANE-SUPPLIED FILTERS, APPLY FOAM

GASKETING TO THE VERTICAL EDGES OF THE

FILTER.

Permanent Filters

To clean permanent filters, wash under a stream of

water to remove dirt and lint. Remove oil filter with a

wash of mild alkali solution. Rinse in clean, hot water

and allow to dry. Coat both sides of the filter by

immersing or spraying it with Air Maze Filter Lote W

or an equivalent. Allow to drain and dry for about 12

hours.

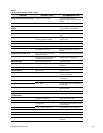

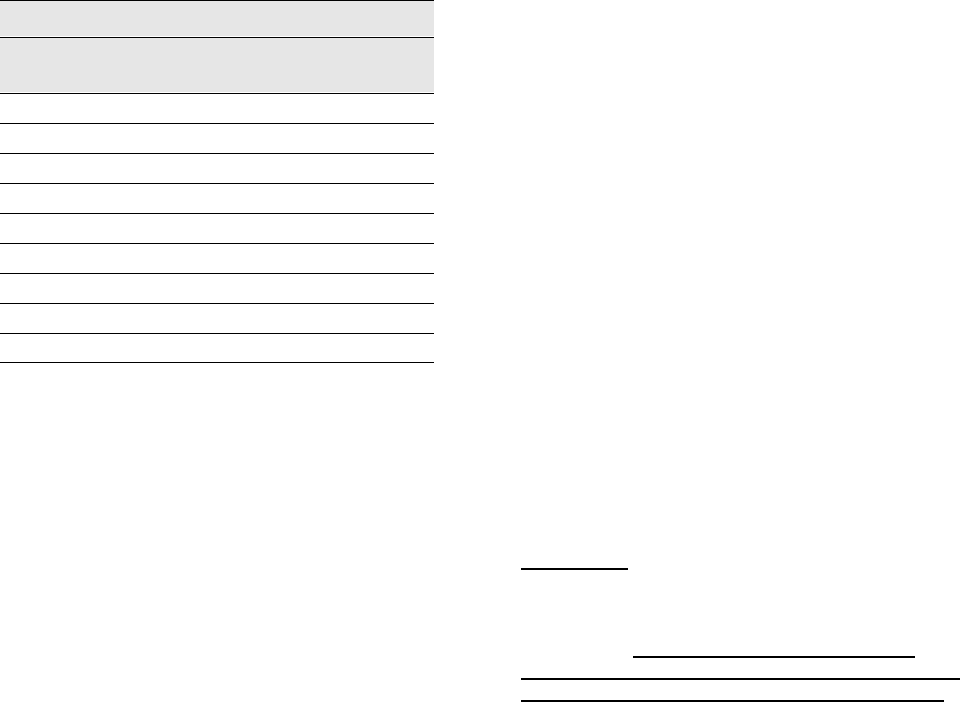

9/16, 18

UNF 118

5/8, 11

UNC 150

5/8, 18

UNF 176

3/4, 10

UNC 254

3/4, 16

UNF 301

7/8, 9

UNC 358

7/8, 14

UNF 422

1, 8

UNC 500

1, 14

UNF 602

Table 48

Minimum Hex Head Bolt Torque in lb-ft

Grade 5 Bolts

Size (inches*)

Thread

Designation

Min. Torque