32 CLCH-IM-16A

Units With More Than One Drain Pan

With the T-Series Climate Changer, each section can

be ordered with or without a drain pan. When more

than one section has a drain pan, you must trap each

section individually. Connecting all drains to a

common line with only one trap will result in

condensate retention, and possible water damage to

the air handler or adjoining space.

If a section has a drain pan for cleaning purposes

only, it does not need a trap; however a cap or shut

off valve should be installed on the drain connection.

Only sections handling condensate, such as a

cooling coil section or eliminator section, require a

trap.

Figure 28

through

Figure 37

are examples of

typical installations.

Coil Piping And Connections

See

Table 27

through

Table 29

for connection sizes.

For supply, vent and drain connections, refer to

Figure 28

through

Figure 37

.

NOTE: DRAIN AND VENT CONNECTIONS ARE

PROVIDED AS STANDARD ON UW, UU, DD, AND D

COILS ONLY. ALL OTHERS, IF REQUIRED, MUST BE

FIELD INSTALLED.

NOTE: DRAIN AND VENT CONNECTIONS ON THE UU

AND UW COILS ARE RECESSED. IF EXTENDED

DRAINS AND VENTS ARE REQUIRED, THEY MUST BE

FIELD PROVIDED.

General Coil Piping Recommendations

Proper installation, piping and trapping is necessary

to ensure satisfactory coil operation and to prevent

operational damage.

q Support all piping independently of the coils.

q Provide swing joints or flexible fittings on all

connections that are adjacent to heating coils in

order to absorb thermal expansion and

contraction strains.

q If ordered with factory mounted controls, install

the control valves. The valves ship separately in

the unit. The contractor should supply the pipe

nipples, couplings, etc.for installation.

NOTE: WHEN USING ELECTRONIC VALVE

ACTUATORS ON CHILLED WATER VALVES, THE

VALVE SHOULD BE MOUNTED ABOVE THE

HORIZONTAL POSITION TO PREVENT COLLECTION

OF CONDENSATE IN THE ACTUATOR ELECTRONIC

CIRCUITS AND SUBSEQUENT ACTUATOR FAILURE.

WHEN USING ELECTRONIC VALVE ACTUATORS ON

HOT WATER OR STEAM COILS, THE ACTUATOR

SHOULD BE INSTALLED APPROXIMATELY 45

DEGREES FROM VERTICAL. VERTICAL

INSTALLATION OF A VALVE ACTUATOR ON A HOT

WATER OR STEAM COIL WILL EXPOSE THE

ACTUATOR TO HIGH TEMPERATURES, RESULTING

IN ACTUATOR FAILURE.

THE EXTERNAL CABINET IS ONLY SUFFICIENTLY

SIZED FOR HOUSING COIL PIPING. ALL VALVES AND

VALVE ACTUATORS MUST BE LOCATED

ELSEWHERE.

For best results, The Trane Company recommends

that a short pipe nipple be used on the coil headers

prior to making any welded flange or welded elbow

type connections.

IMPORTANT: TEFLON TAPE OR PIPING COMPOUND

SHOULD NOT BE USED FOR ANY FIELD

CONNECTIONS BECAUSE ITS HIGH LUBRICITY MAY

ALLOW CONNECTIONS TO BE OVER-TIGHTENED,

RESULTING IN DAMAGE TO THE COIL HEADER.

NOTE: USE A BACK-UP WRENCH WHEN ATTACHING

PIPING TO COILS WITH TUBE HEADER

CONSTRUCTION TO PREVENT DAMAGE TO THE COIL

HEADER. DO NOT USE BRASS CONNECTORS. BRASS

DISTORTS EASILY AND COULD CAUSE CONNECTION

LEAKS.

When attaching the piping to the coil header, make

the connection only tight enough to prevent leaks.

Maximum recommended torque is 200 pound-feet.

Use pipe sealer on all thread connections.

After completing the piping connections, use mastic

to seal between the pipe and casing before insulating

the pipe.

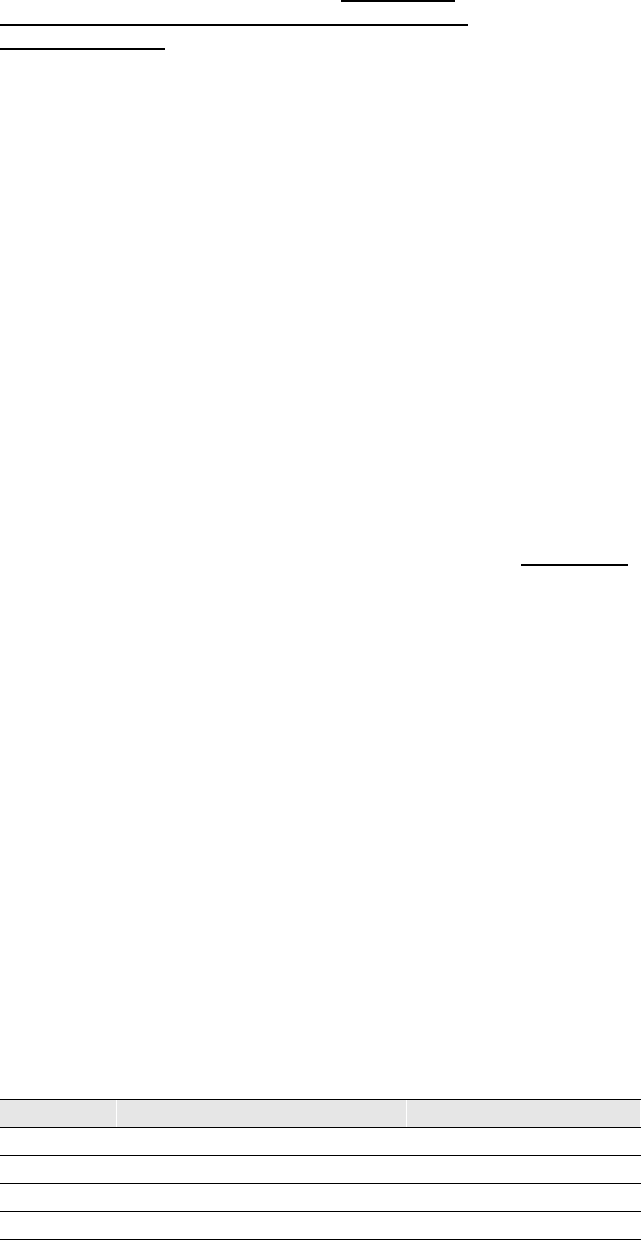

Table 27

Shipping Coil Water and Steam Connection Sizes

Coil Type Header Height Supply Return Drain/Vent

W, WA 18, 24, 30, 33 2-1/2 2-1/2 1/2

W 42, 48, 54 2-1/2 2-1/2 1/2

D, DD, WD, K 18, 24, 30, 33 2-1/2 2-1/2 1/2

P2 18, 24, 30 3/4 3/4 1/2