Installation and Maintenance 55

Over-tensioning of belts can cause damage to

bearings, shafts, and drive components. Belts should

not squeal at start-up. Belt tension should be

rechecked after 8 hours, 24 hours, and 100 hours of

operation and monthly thereafter. When the belt is in

operation, the tight side of the belt should form a

straight line from sheave with only a slight bow on the

slack side.

Fan Belt Tension

NOTE: FAN BELT TENSION SHOULD BE CHECKED AT

LEAST THREE TIMES DURING THE FIRST DAYS OF

OPERATION, SINCE THERE IS A RAPID DECREASE IN

TENSION UNTIL BELTS SETTLE IN. REFER TO THE

DRIVE STICKER FOR PROPER TENSION.

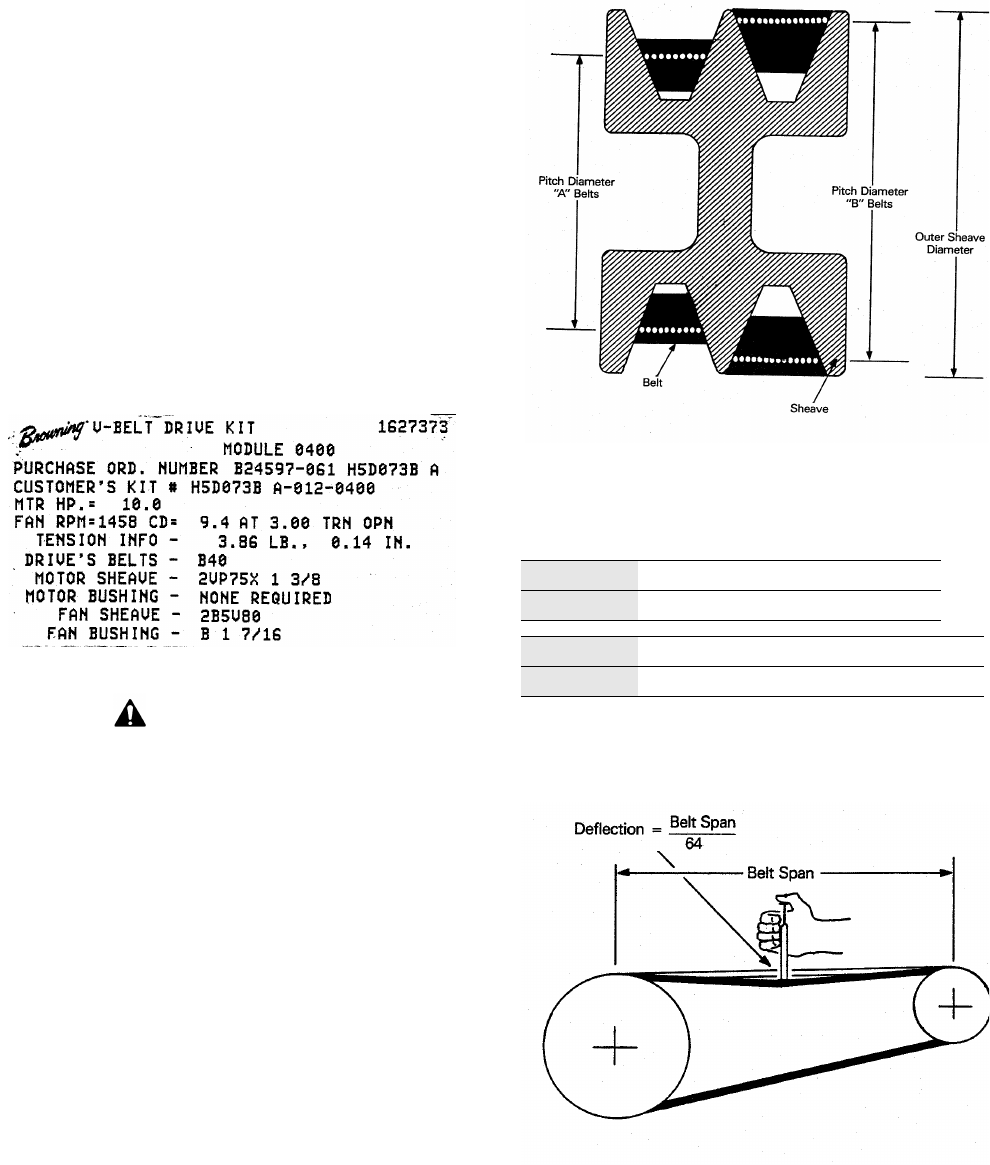

Figure 46

Typical Drive Belt Label

WARNING

Disconnect electrical power

source and allow all rotating

equipment to stop completely

before inspecting or servicing the

unit. Failure to do so may result in

personal injury or death from elec-

trical shock or moving parts.

Disconnect electrical power prior

to access into a fan or ductwork.

Even when locked out electrically,

fans may cause injury or damage if

the impeller is subject to “wind-

milling.” The impeller should be

secured to physically restrict rota-

tional movement. Failure to secure

impeller can cause severe per-

sonal injury or death.

Figure 47

Fan Sheave Pitch Diameter

Figure 48

Belt Tension Measurement

Table 46

Values for K-Factor (Belt Cross Section Types)

Belt Type

ABCDE3L4L

K Factor

8 13408095 6 6

Belt Type

5L 3V 5V 8V AX BX CX DX

K Factor

6 6 12 25 11 18 54 101