7.7

Section 7

Cooling System

7

Figure 7-12. Adapter Installed onto the Tester.

2. Pressurize the tester to 15 psi.

3. Observe the indicated pressure. It should hold

steady and not decrease or leak down.

If leakage is detected, the cap should be

replaced. If the tester pressure is increased to 16

psi, or above, the cap should then ‘‘bleed off’’ this

excess pressure.

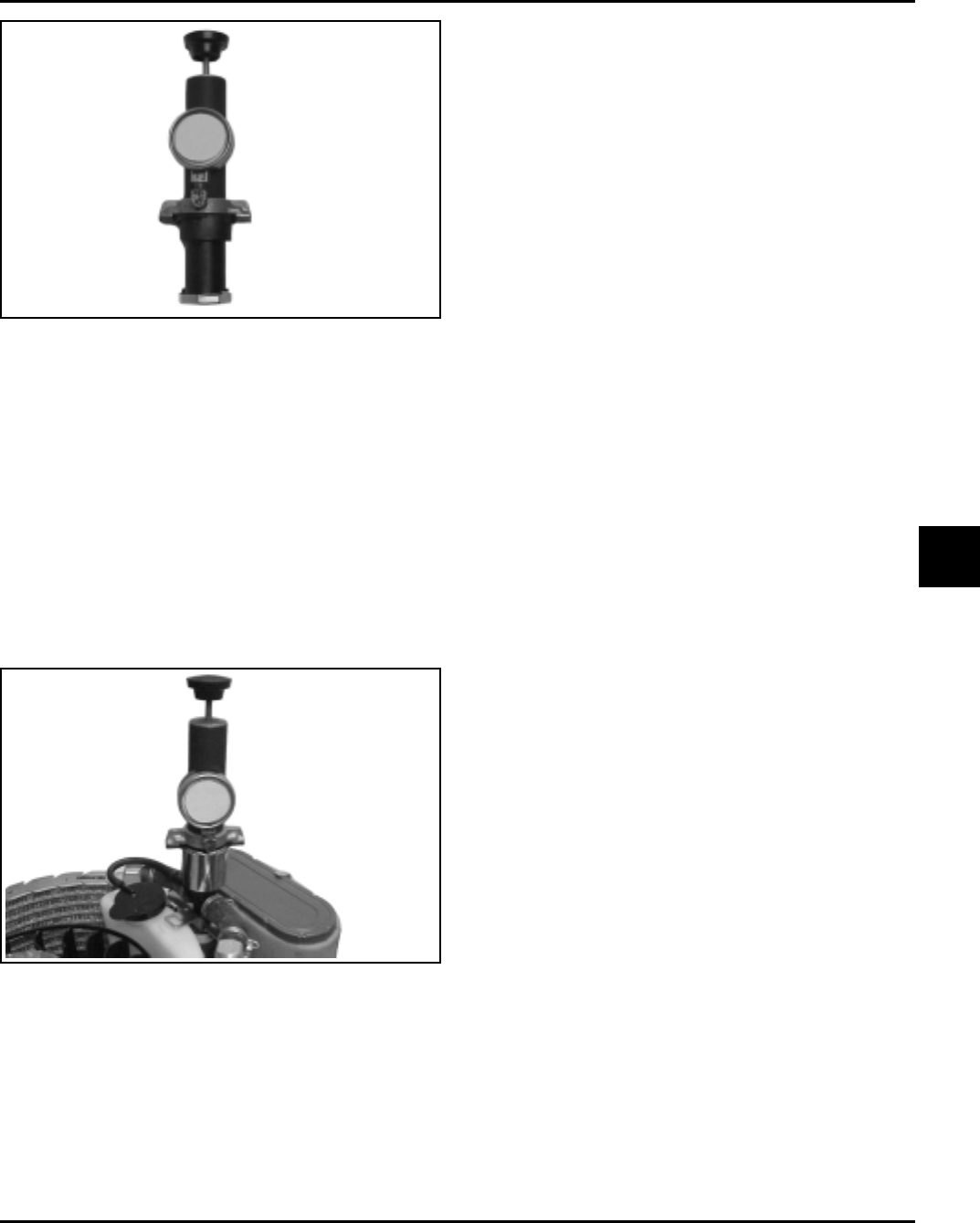

4. Install and lock the system adapter and tester

onto the neck of the cooling system. Pressurize

the tester to 14-15 psi. See Figure 7-13.

5. Observe the system pressure on the gauge.

Gauge holds steady pressure

If the gauge needle holds steady, there should be

no serious leaks in the system. It is

recommended that all connections be checked for

overall condition anyway, using a flashlight.

Pressure drops slowly

If the gauge needle drops slowly it indicates the

presence of a small leak or seepage. Check all

components and connections for signs of

leakage. Check the condition of the radiator

hoses. If they swell excessively while testing the

system, they may be weak and should be

replaced.

Pressure drops quickly

A steady drop or loss of pressure indicates

serious leakage is occurring within the system,

which must be located and corrected before the

engine is returned to service.

If a pressure loss is noted:

1. With pressure on the system, apply a soap/water

solution and check all joint connections, hoses,

and cooling system components for external

leakage. Repair or replace as required.

2. Remove the dipstick and check the appearance

of the oil in the crankcase. Another method would

be to remove an oil drain plug and drain a small

amount of oil for inspection. A milky or an opaque

color, similar to chocolate milk, indicates the

presence of engine coolant in the oil. Check for a

blown head gasket (step 3 below) or a possible

crack or internal leakage from the water jacket.

3. Remove the spark plugs. Apply 14-15 lbs. of

pressure and listen/inspect for internal coolant

leakage into the cylinder/combustion chambers.

This can denote a head gasket failure/leak. If

required, further test by performing a ‘‘Cylinder

Leakdown Test’’ as described in Section 3.

Figure 7-13. Adapter and Tester Installed.

15 psi

14-15

psi