5.3

Section 5

Fuel System and Governor

5

2. Remove the hex. flange screws (securing pump

to blower housing) and fuel pump.

3. Remove the vacuum line that connects the pump

to the crankcase.

4. Install a new pump using the hex. flange screws.

NOTE: Make sure the orientation of the new

pump is consistent with the removed

pump. Internal damage may occur if

installed incorrectly.

5. Connect vacuum line between pulse pump and

crankcase. Route line so there are no low spots

where oil could collect.

6. Tighten the hex. flange screws to 2.3 N·m

(20 in. lb.).

7. Connect the fuel lines to the inlet and outlet

fittings.

Carburetor

General

Engines in this series are equipped with fixed main jet

carburetors. Most applications also utilize a fuel shut-

off solenoid, which is installed in place of the fuel bowl

retaining screw. All carburetors feature the self-

relieving choke components shown in the exploded

view on page 5.9. These carburetors include three

main circuits which function as follows.

Float Circuit: Fuel level in the bowl is maintained by

the float and fuel inlet needle. The buoyant force of the

float stops fuel flow when the engine is at rest. When

fuel is being consumed, the float will drop and fuel

pressure will push the inlet needle away from the seat,

allowing more fuel to enter the bowl. When demand

ceases, the buoyant force of the float will again

overcome the fuel pressure and stop the flow.

Fuel Pump

General

These engines are equipped with an external pulse

fuel pump. The pumping action is created by the

oscillation of positive and negative pressures within

the crankcase. This pressure is transmitted to the

pulse pump through a rubber hose connected between

the pump and crankcase. The pumping action causes

the diaphragm on the inside of the pump to pull fuel in

on its downward stroke and to push it into the

carburetor on its upward stroke. Two check valves

prevent fuel from going backward through the pump.

Performance

Minimum fuel delivery rate must be 7.5 L/hr.

(2 gal./hr.) with a pressure at .3 psi and a fuel lift of

24". A 1.3 L/hr. (.34 gal./hr.) fuel rate must be

maintained at 5 Hz.

Replacing the Fuel Pump

Replacement pumps are available through your

source of supply. To replace the pulse pump follow

these steps. Note orientation of pump before

removing.

1. Disconnect the fuel lines from the inlet and outlet

fittings.

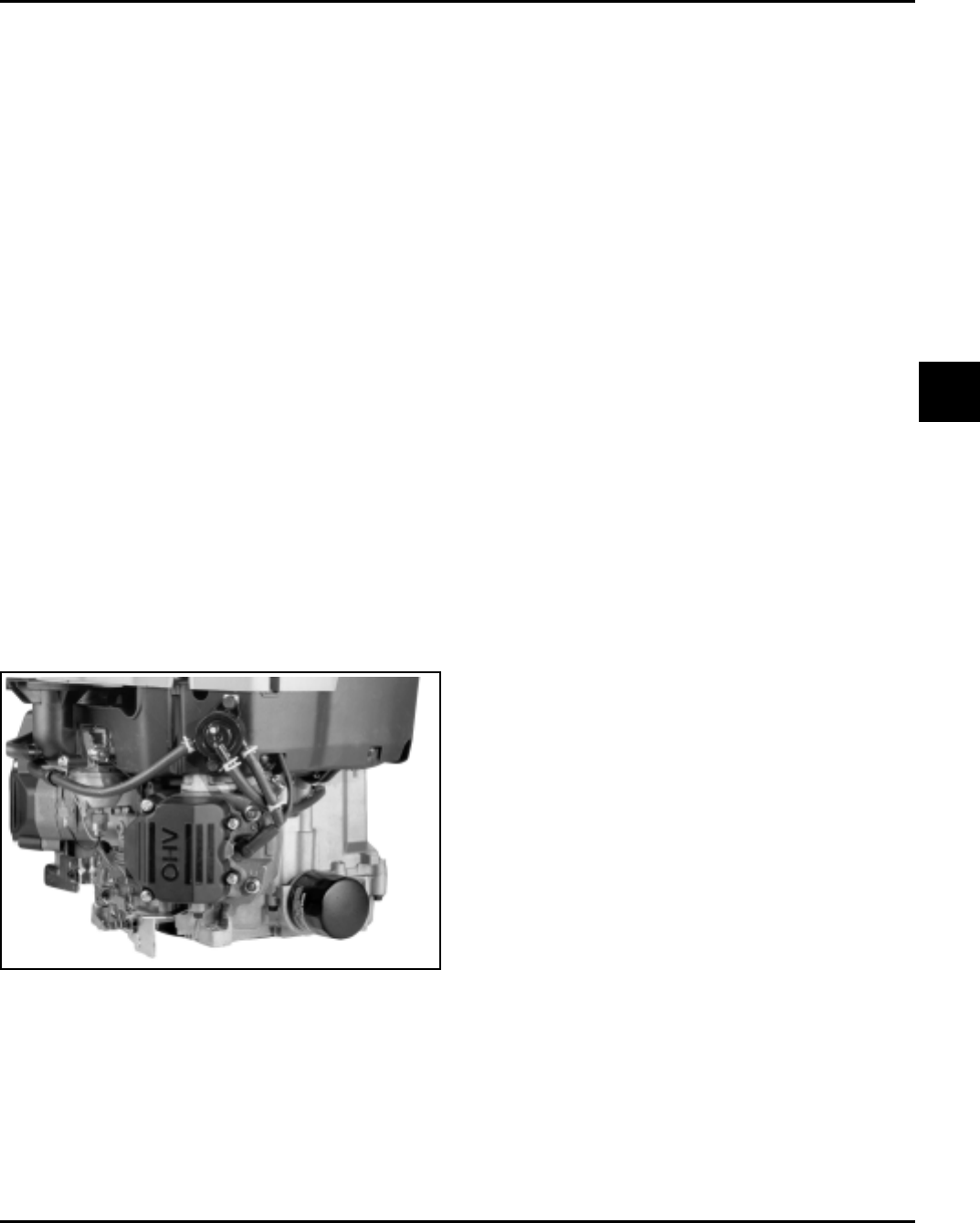

Figure 5-1. Fuel Pulse Pump Connections.