11.5

Section 11

Reassembly

11

Determining Camshaft End Play

1. Install the shim removed during disassembly onto

the camshaft.

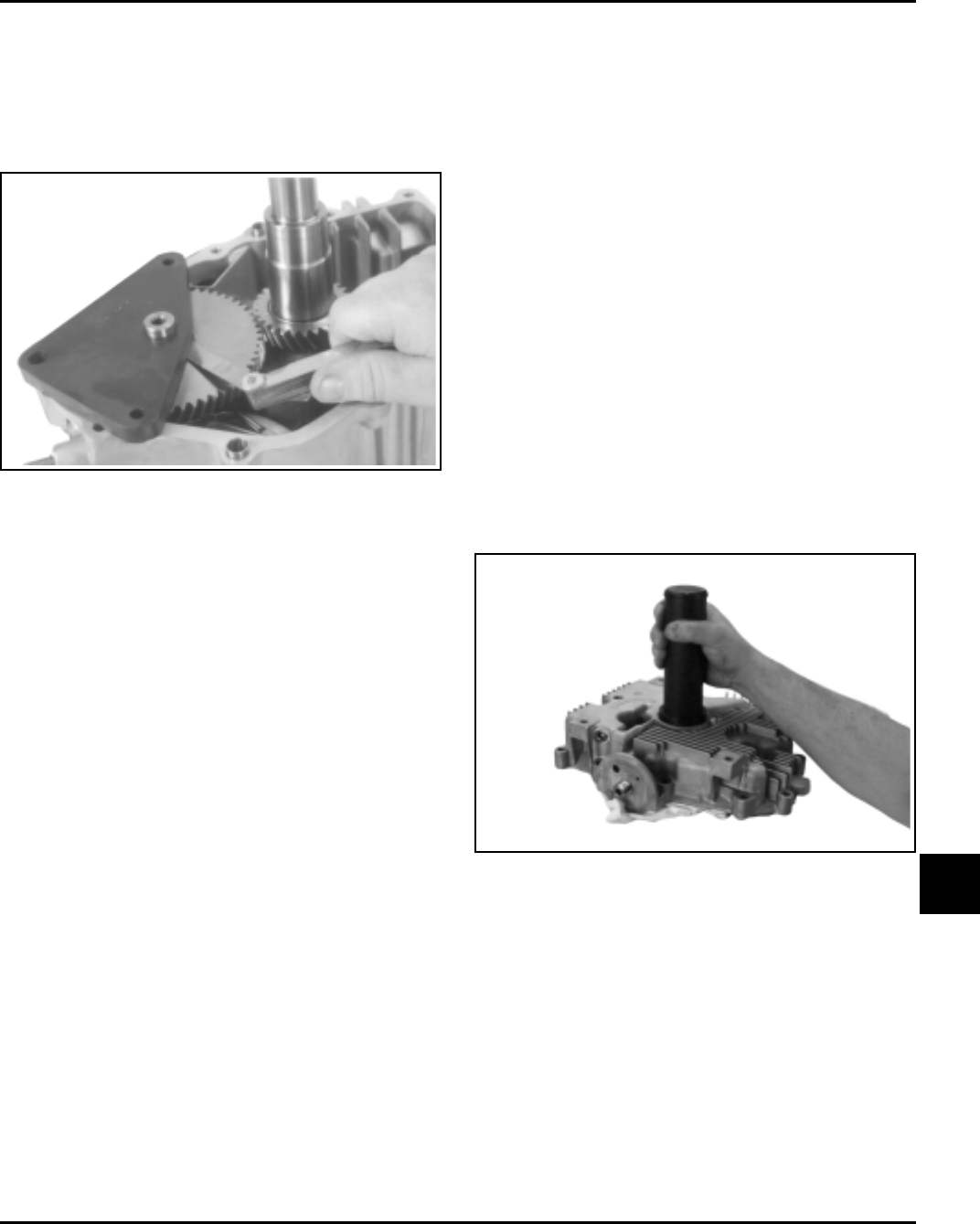

2. Position the camshaft end play checking tool on

the camshaft. See Figure 11-12.

Figure 11-12. Checking Camshaft End Play.

3. Apply pressure on the end play tool, pushing the

camshaft toward the crankshaft. Use a feeler

gauge to measure the camshaft end play between

the shim spacer and the end play tool. Camshaft

end play should be 0.076/0.127 mm (0.003/

0.005 in.).

4. If the camshaft end play is not within the specified

range, remove the end play tool and replace shim

as necessary.

Several color coded shims are available.

White: 0.69215/0.73025 mm (0.02725/0.02875 in.)

Blue: 0.74295/0.78105 mm (0.02925/0.03075 in.)

Red: 0.79375/0.83185 mm (0.03125/0.03275 in.)

Yellow:0.84455/0.88265 mm (0.03325/0.03475 in.)

Green:0.89535/0.99345 mm (0.03525/0.03675 in.)

Gray: 0.94615/0.98425 mm (0.03725/0.03875 in.)

Black: 0.99695/1.03505 mm (0.03925/0.04075 in.)

5. Reinstall the camshaft end play checking tool

and recheck end play.

6. Repeat steps 4 and 5 until end play is within

specified range.

Oil Pump Assembly

The oil pump is mounted in the oil pan. If service was

required, and the oil pump was removed, refer to the

assembly procedures under ‘‘Oil Pump Assembly’’ in

Section 10.

Governor Assembly

The governor assembly is located inside the oil pan. If

service was required, and the governor was removed,

refer to the assembly procedures under ‘‘Governor

Assembly’’ in Section 10.

Install Oil Seal in Oil Pan

1. Check to make sure that there are no nicks or

burrs in the crankshaft bore of the oil pan.

2. Apply a light coat of engine oil to the outside

diameter of the oil seal.

3. Drive the oil seal into the oil pan using a seal

driver. Make sure the oil seal is installed straight

and true in bore and that the tool bottoms against

the oil pan. See Figure 11-13.

Figure 11-13. Installing Oil Pan Seal.

Install Oil Pan Assembly

RTV silicone sealant is used as a gasket between the

oil pan and the crankcase.

NOTE: Always use fresh sealant. Using outdated

sealant can result in leakage.

1. Prepare the sealing surfaces of the crankcase

and oil pan as directed by the sealant

manufacturer.

2. Check to make sure that there are no nicks or

burrs on the sealing surfaces of the oil pan or

crankcase.